The primary environmental issue with modern Wellington boots stems from their most common material: polyvinyl chloride, or PVC. This oil-derived plastic is fundamentally at odds with sustainability because it is non-biodegradable, cannot be recycled, and its production and disposal release harmful pollutants into the air and water.

The utility and affordability of modern PVC Wellies come at a significant environmental cost. From their fossil fuel origins to a final destination in a landfill where they will persist for centuries, their entire lifecycle presents a challenge for environmental stewardship.

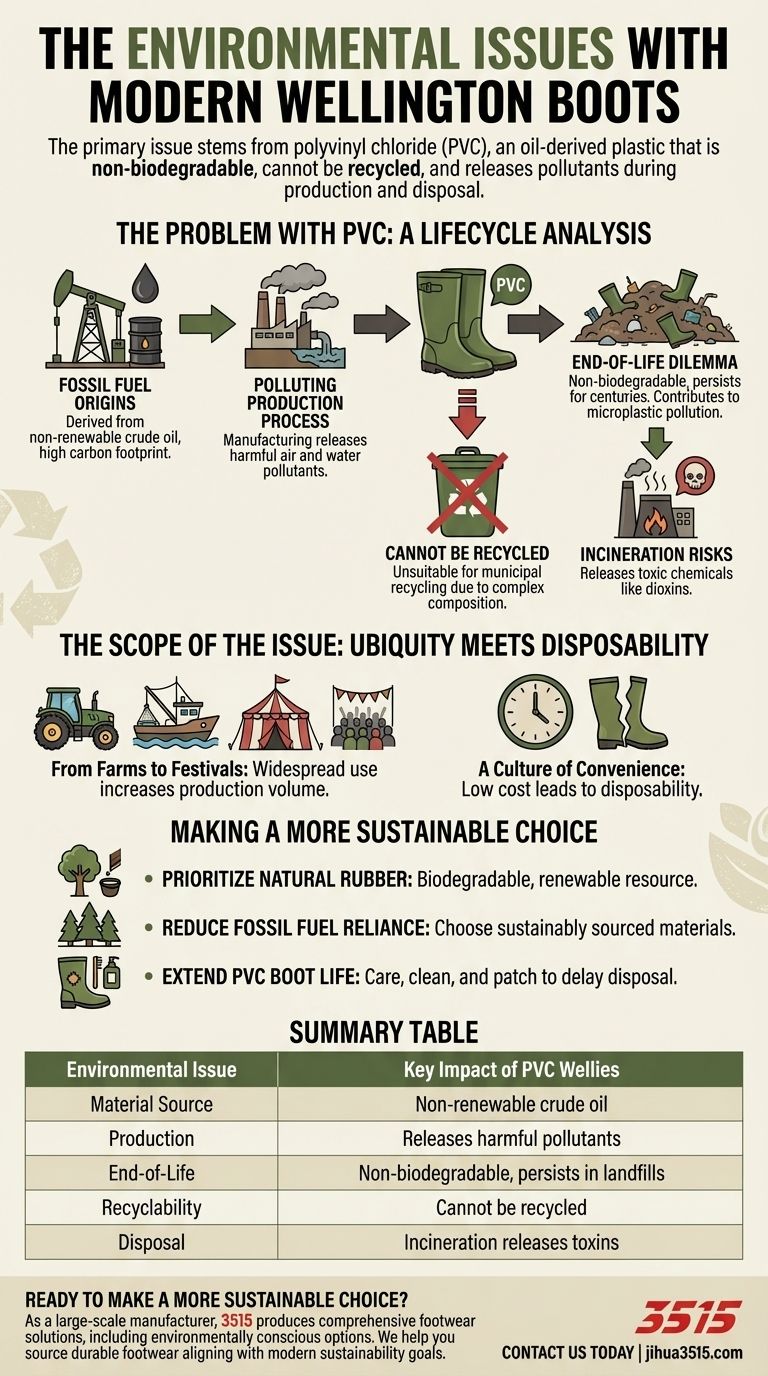

The Problem with PVC: A Lifecycle Analysis

To grasp the full environmental impact of a modern Welly, we must look at its journey from creation to disposal. The problem is not just what happens when you throw it away, but how it's made in the first place.

Fossil Fuel Origins

The journey begins with crude oil. PVC is a petroleum-based plastic, meaning its raw materials are extracted from the earth, a process with a significant carbon footprint and environmental risk.

This reliance on a non-renewable resource makes the entire product lifecycle inherently unsustainable from the start.

The Polluting Production Process

Manufacturing PVC is an intensive industrial process. The creation and chemical synthesis involved are known to release pollutants that harm both air and water quality in the regions surrounding the factories.

The End-of-Life Dilemma

This is where the environmental cost becomes most apparent. Unlike natural materials, PVC does not decompose in a meaningful timeframe.

Once a pair of PVC Wellies is discarded, it is destined to exist for centuries. It does not biodegrade, but simply breaks down into smaller plastic fragments over time, contributing to microplastic pollution.

Furthermore, PVC boots cannot be placed in your standard recycling bin. The complex chemical composition and additives used in footwear make them unsuitable for most municipal recycling programs, meaning their only destination is the landfill or incinerator.

When PVC is incinerated in an attempt to recover energy from waste, it can release toxic chemicals, including dioxins, which are potent environmental pollutants.

The Scope of the Issue: Ubiquity Meets Disposability

The material choice is compounded by the sheer volume of boots being produced. Their practicality has made them a staple in numerous settings, scaling the environmental problem significantly.

From Farms to Festivals

Wellington boots are essential equipment in agriculture, fishing, and heavy industry, where their durability and protective qualities are invaluable.

Simultaneously, they have become fashion items, popular at outdoor events like music festivals. This widespread use means millions of pairs are produced and sold annually.

A Culture of Convenience

The low cost and rugged application of PVC Wellies can lead to a perception of them as disposable. Whether worn for a single festival weekend or used until they split on a farm, their ultimate destination is the waste stream, adding to the ever-growing plastic burden on the planet.

Making a More Sustainable Choice

Understanding the material science behind your boots is the key to making a better decision. Your purchasing power can favor materials with a less damaging lifecycle.

- If your primary focus is minimizing landfill waste: Prioritize boots made from natural, biodegradable rubber and actively avoid PVC.

- If your primary focus is reducing reliance on fossil fuels: Choose footwear made from renewable resources, such as natural rubber sourced from sustainably managed forests.

- If you already own PVC boots: The most sustainable action is to extend their life. Care for them, clean them, and patch any leaks to keep them in use and out of the landfill for as long as possible.

Choosing footwear thoughtfully by considering its entire lifecycle is a critical step toward reducing your personal environmental impact.

Summary Table:

| Environmental Issue | Key Impact of PVC Wellies |

|---|---|

| Material Source | Derived from non-renewable crude oil (fossil fuels). |

| Production | Manufacturing process releases harmful air and water pollutants. |

| End-of-Life | Non-biodegradable; persists in landfills for centuries. |

| Recyclability | Cannot be recycled in standard municipal programs. |

| Disposal | Incineration risks releasing toxic chemicals like dioxins. |

Ready to make a more sustainable choice for your footwear needs?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including environmentally conscious options. We can help you source or develop durable footwear that aligns with modern sustainability goals, reducing reliance on materials like PVC.

Contact us today to discuss how we can provide high-quality, responsible footwear solutions for your business.

Visual Guide

Related Products

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

People Also Ask

- What features should one look for in high-quality gardening boots? Ensure Dry, Comfortable Feet All Day

- What should you consider when choosing shoes for wet weather? Key Features for Dry, Safe Feet

- How can wellies be made sustainable? Shift to Natural Rubber & Ethical Production

- What should adults consider when buying wellington boots? Find the Perfect Fit for Your Needs

- What special features should be considered when choosing Wellington boots? A Guide to Safety, Fit & Performance

- What are some features of high-quality eco-friendly wellies? Look for Durability, Ethics, and Eco-Credentials

- What are some common uses for wellington boots? Essential Footwear for Wet & Muddy Conditions

- What should you avoid when drying rubber boots? The #1 Mistake That Ruins Them