The primary materials used in safety shoes are a strategic combination of traditional leathers, advanced synthetics like polyurethane and rubber, and specialized protective reinforcements. For impact and puncture resistance, materials such as steel, composite plastics, aluminum, and Kevlar are integrated into the shoe's core structure.

A safety shoe is a system of specialized components. Each material—from the upper to the toe cap and outsole—is deliberately selected for its unique protective properties, whether it's impact resistance, puncture-proofing, heat resistance, or grip.

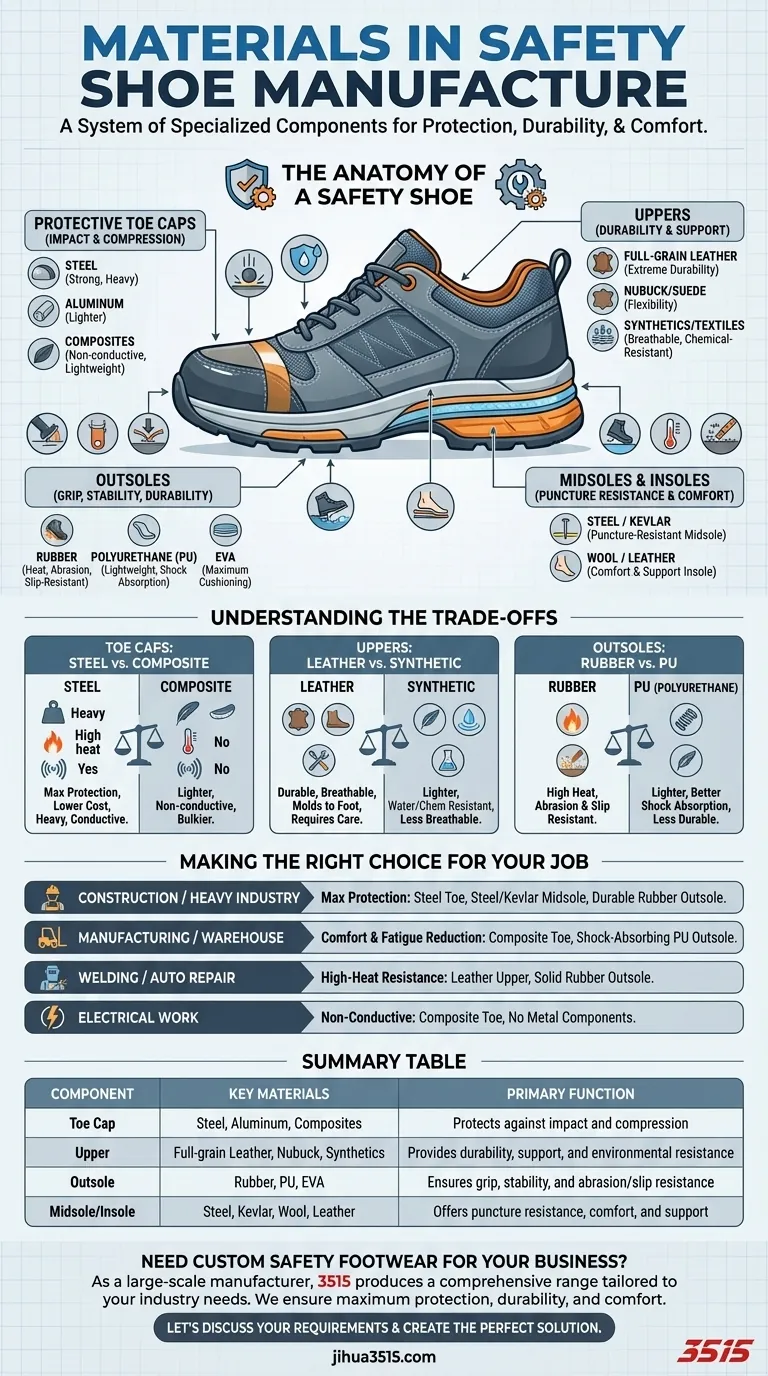

The Anatomy of a Safety Shoe: A Component-by-Component Breakdown

To truly understand safety footwear, you must look at it as an engineered product. The materials are chosen to fulfill a specific function in each part of the shoe.

Protective Toe Caps (The First Line of Defense)

The toe cap is the most recognized safety feature, designed to protect against compression and impact.

The most common materials are steel, aluminum, and composites (like carbon fiber, plastic, or Kevlar). Steel offers maximum strength, while composites are lighter and do not conduct electricity or temperature.

Uppers (Balancing Durability and Comfort)

The upper part of the shoe protects the foot from the top and sides while providing structural support.

Materials range from full-grain leather, known for its extreme durability, to nubuck or suede leather for more flexibility. Synthetics and textiles are also common, often used to improve breathability or provide resistance to chemicals and water.

Outsoles (The Foundation of Safety)

The outsole is the critical point of contact with the ground, dictating the shoe's grip, stability, and durability.

The three main materials are Rubber, Polyurethane (PU), and Ethylene Vinyl Acetate (EVA). Rubber offers excellent resistance to abrasion, heat, and slips. PU provides great shock absorption and is lightweight, while EVA offers the most cushioning but is the least durable of the three.

Midsoles and Insoles (Puncture Resistance and Support)

The midsole provides puncture resistance, while the insole delivers comfort and support.

Puncture-resistant midsoles are often made of steel or flexible woven fabrics like Kevlar. Insoles are typically made from comfortable, moisture-absorbing materials like wool, leather, or other non-woven fabrics.

Understanding the Trade-offs

Choosing the right safety shoe involves balancing competing material properties. No single material is perfect for every application.

Steel vs. Composite Toe Caps

Steel is the traditional choice, offering maximum protection at a lower cost. However, it's heavy, conducts heat and cold, and will set off metal detectors.

Composite toe caps are significantly lighter and non-conductive, making them ideal for electricians or workers in extreme temperatures. Their primary trade-off is that they can be bulkier than steel to achieve the same safety rating.

Leather vs. Synthetic Uppers

Leather is exceptionally durable, breathable, and molds to the wearer's foot over time. Its main drawback is that it can be heavy and requires maintenance to retain its properties.

Synthetics like PVC and advanced textiles are often lighter, more water-resistant, and can be designed for specific chemical resistance. However, they typically offer less breathability than natural leather.

The Outsole Dilemma: PU vs. Rubber

Rubber outsoles are the superior choice for high-heat environments like welding or asphalt work. They also provide excellent slip and abrasion resistance.

Polyurethane (PU) outsoles are lighter and offer better shock absorption, making them ideal for workers who spend long hours on hard concrete floors in warehouses or manufacturing plants.

Making the Right Choice for Your Job

Your work environment is the single most important factor in selecting the right materials for your safety footwear.

- If your primary focus is construction or heavy industry: You need maximum protection from impact and puncture, so look for steel toes and steel or Kevlar midsoles with a durable rubber outsole.

- If your primary focus is manufacturing or warehouse work: Prioritize comfort and fatigue reduction with a lightweight composite toe and a shock-absorbing polyurethane (PU) outsole.

- If your primary focus is welding or auto repair: You require high-heat resistance, making a leather upper and a solid rubber outsole the only reliable choice.

- If your primary focus is electrical work: Your absolute priority is eliminating conductivity, so choose a boot with a composite toe and no metal components.

Understanding these materials empowers you to choose footwear that is not just compliant, but a genuine asset to your daily safety and performance.

Summary Table:

| Component | Key Materials | Primary Function |

|---|---|---|

| Toe Cap | Steel, Aluminum, Composites (Carbon Fiber, Kevlar) | Protects against impact and compression |

| Upper | Full-grain Leather, Nubuck, Synthetics (PVC, Textiles) | Provides durability, support, and environmental resistance |

| Outsole | Rubber, Polyurethane (PU), Ethylene Vinyl Acetate (EVA) | Ensures grip, stability, and abrasion/slip resistance |

| Midsole/Insole | Steel, Kevlar, Wool, Leather | Offers puncture resistance, comfort, and support |

Need Custom Safety Footwear for Your Business?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, tailored to your specific industry needs—from heavy-duty construction to specialized electrical work.

We ensure maximum protection, durability, and comfort by expertly selecting the right materials for every component.

Let's discuss your requirements and create the perfect safety solution for your team.

Contact 3515 today for a quote

Visual Guide

Related Products

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Waterproof Nubuck Safety Boots for Wholesale

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- What causes corns in steel toe boots and how can they be prevented? Master the Perfect Fit to Avoid Pain

- What is the importance of choosing the right size for steel toe boots? Avoid Injury and Boost Productivity

- What are the consequences of not wearing safety shoes? Protect Your Feet from Severe Workplace Injuries

- What are the key features of a work boot? Essential Protection for Hazardous Work Environments

- What types of safety toe boots are available for different job requirements? Choose the Right Protection for Your Work