Failing to wear required safety shoes is not a minor oversight; it's a direct exposure to a range of preventable and often severe workplace injuries. The most immediate consequences include serious foot damage from falling objects or punctures from sharp materials on the ground. Beyond these obvious impacts, it also opens you up to slips and falls, chemical burns, electrical shock, and injuries from extreme temperatures.

Safety footwear is not merely about protecting your toes from a single impact. It is a critical engineering control designed to mitigate a wide spectrum of common and severe workplace hazards that can lead to debilitating, life-altering injuries.

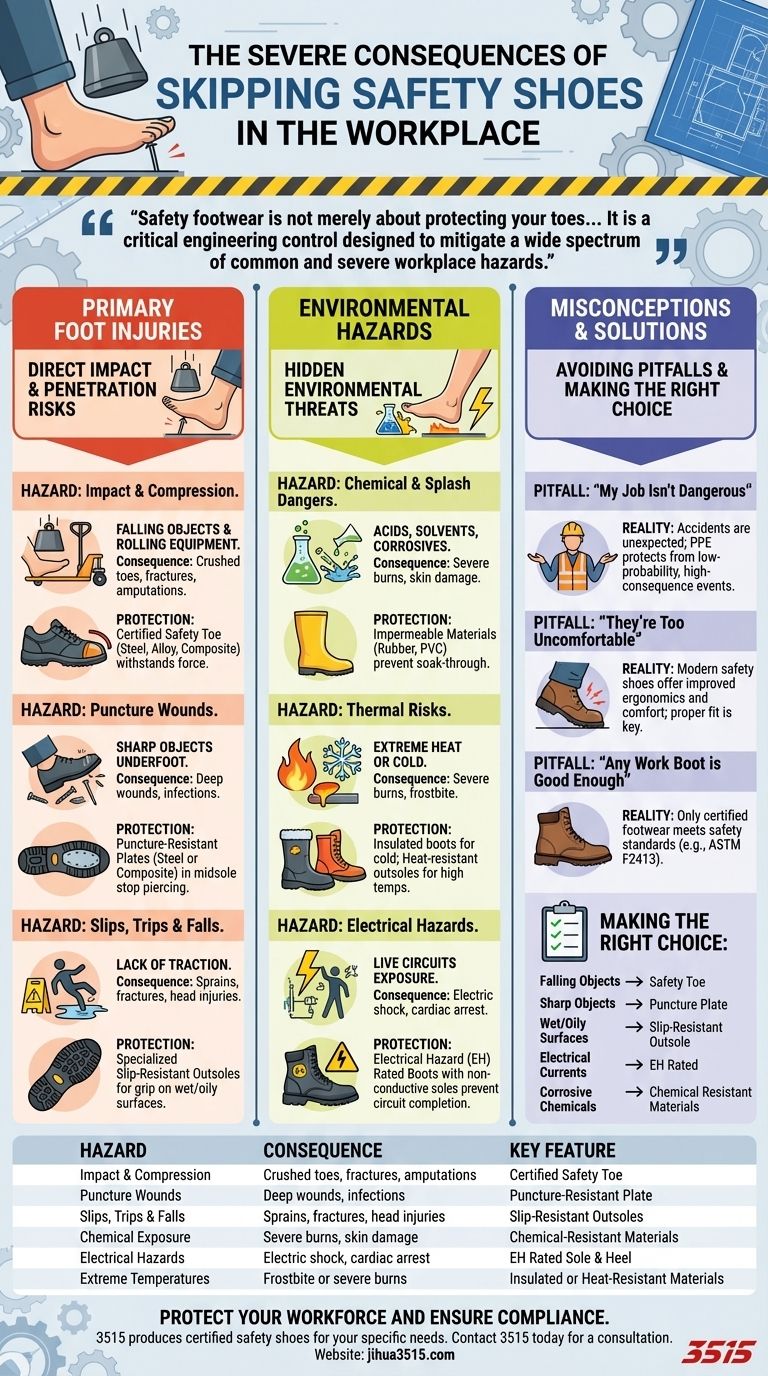

The Primary Categories of Foot Injury

To understand the consequences, we must first break down the specific risks that safety footwear is designed to prevent. Each feature of a safety shoe corresponds to a distinct category of hazard.

Impact and Compression

This is the most well-known risk. Dropped tools, falling materials, or rolling equipment like carts and pallet jacks can easily cause crushing injuries to the feet.

Safety toes, made from materials like steel, aluminum alloy, or composite materials, are engineered to withstand significant force, preventing fractures and amputations.

Puncture Wounds

Construction sites, manufacturing floors, and maintenance areas are often littered with sharp objects like nails, screws, and metal shavings.

A standard shoe sole offers no protection. Puncture-resistant plates, often made of steel or advanced composite fabrics, are built into the midsole of safety shoes to stop these objects from piercing through to your foot.

Slips, Trips, and Falls

According to safety regulators, slips, trips, and falls are among the most common causes of all workplace injuries, and the consequences can be severe.

Regular shoes lack the grip needed for industrial environments. Safety footwear uses specialized slip-resistant outsoles with tread patterns and compounds designed to maintain traction on wet, oily, or uneven surfaces.

Environmental Hazards Beyond the Obvious

Many risks are not from physical force but from the environment itself. Specialized safety footwear is essential for protecting against these less visible but equally dangerous threats.

Chemical and Splash Dangers

Workers in labs, chemical plants, and cleaning operations can be exposed to acids, solvents, and other corrosive materials.

Footwear made from materials like PVC or specialized rubber is designed to be impermeable, preventing dangerous chemicals from soaking through and causing severe burns or skin damage.

Thermal Risks

Working near furnaces, molten metal, or in outdoor winter conditions presents significant thermal hazards.

Insulated boots protect against frostbite in cold environments, while footwear with high-heat outsoles and materials can prevent severe burns in high-temperature settings like foundries or welding shops.

Electrical Hazards

This is one of the most critical and misunderstood areas of foot protection. For electricians or maintenance staff working near live circuits, the body can become a path for electricity.

Electrical Hazard (EH) rated boots are constructed with non-conductive soles and heels. This feature insulates you from the ground, helping to prevent the completion of an electrical circuit through your body in the event of accidental contact.

Common Misconceptions and Pitfalls

Trusting in myths or assumptions about safety footwear can be just as dangerous as ignoring the rules outright. Understanding these common pitfalls is crucial for true on-the-job safety.

"My Job Isn't That Dangerous"

Many workers underestimate the risks present in their environment, believing an accident is unlikely to happen to them.

This thinking is a fallacy. Serious accidents are almost always unexpected. The purpose of personal protective equipment (PPE) is to protect you from low-probability but high-consequence events.

"They're Too Uncomfortable"

This is a common complaint, but it often stems from improper fit or outdated equipment.

Modern safety shoes have seen dramatic improvements in ergonomics, weight, and comfort. The temporary discomfort of breaking in a new pair of properly-fitted boots is insignificant compared to the long-term pain and disability of a serious foot injury.

"Any Work Boot is Good Enough"

A standard leather work boot is not a safety shoe. It lacks the certified and tested protective features required to mitigate industrial hazards.

Always look for the official certification markings (such as ASTM F2413 in the United States) that guarantee the footwear has been tested to meet specific safety standards for impact, compression, and other hazards.

Making the Right Choice for Your Goal

Selecting the correct safety footwear is not a one-size-fits-all decision. It must be based on a clear assessment of the specific risks in your work environment.

- If your primary risk is falling objects: Ensure your footwear has a certified safety toe (steel, alloy, or composite).

- If your primary risk is sharp objects underfoot: You require footwear with a puncture-resistant plate built into the midsole.

- If you work on wet or oily surfaces: Prioritize a high-traction, slip-resistant outsole designed for those conditions.

- If you are exposed to electrical currents: You must use footwear specifically rated for Electrical Hazard (EH) protection.

- If you handle corrosive chemicals: Select boots made from impermeable materials like rubber or PVC that are rated for chemical resistance.

Ultimately, wearing the correct safety footwear is a non-negotiable part of professional responsibility, safeguarding not just your feet, but your entire livelihood.

Summary Table:

| Hazard Type | Potential Consequence | Key Protective Feature in Safety Shoes |

|---|---|---|

| Impact & Compression | Crushed toes, fractures, amputations | Certified Safety Toe (Steel, Alloy, Composite) |

| Puncture Wounds | Deep foot wounds, infections | Puncture-Resistant Midsole Plate |

| Slips, Trips & Falls | Sprains, fractures, head injuries | Slip-Resistant Outsoles |

| Chemical Exposure | Severe burns, skin damage | Chemical-Resistant Materials (e.g., Rubber, PVC) |

| Electrical Hazards | Electric shock, cardiac arrest | Electrical Hazard (EH) Rated Sole & Heel |

| Extreme Temperatures | Frostbite or severe burns | Insulated or Heat-Resistant Materials |

Protect your workforce and ensure compliance with the right safety footwear.

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear designed to mitigate the specific hazards your workers face—from impact and puncture resistance to electrical hazard protection.

Let us help you equip your team with durable, comfortable, and compliant safety footwear that safeguards their well-being and your business.

Contact 3515 today for a consultation and to discuss your specific needs.

Visual Guide

Related Products

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Waterproof Nubuck Safety Boots for Wholesale

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- What biomechanical factors are essential in safety shoe outsole design? Expert Guide to Trip and Fall Prevention

- What is the importance of safety footwear in various industries? Essential Protection for Your Workforce

- What are ASTM rated security guard safety boots? Ensure Foot Protection and All-Day Comfort

- How does puncture-resistant footwear work? Your Ultimate Guide to Foot Safety

- What is the core function of an Asset and Service Information System (ASIS)? Optimize Safety Footwear Lifecycles

- What specific protective features do professional safety shoes provide for stroke survivors? Enhance Workplace Safety

- What role do pressure sensors play in the detection nodes of safety footwear? Smart Compliance for Construction Sites

- What organization defines the OSHA standard for safety shoes in the US? A Guide to Compliance & Worker Protection