The key features of a work boot are a carefully engineered system of protection, durability, and support designed for hazardous environments. At its core, a quality boot combines a protective safety toe, typically made of steel or composite material, with thick, durable upper materials like cowhide and a robust, puncture-resistant sole to shield the wearer from common job site dangers.

A work boot is not a single product but a system of integrated features. The right choice moves beyond a simple checklist to a careful evaluation of your specific work environment and the daily hazards you face.

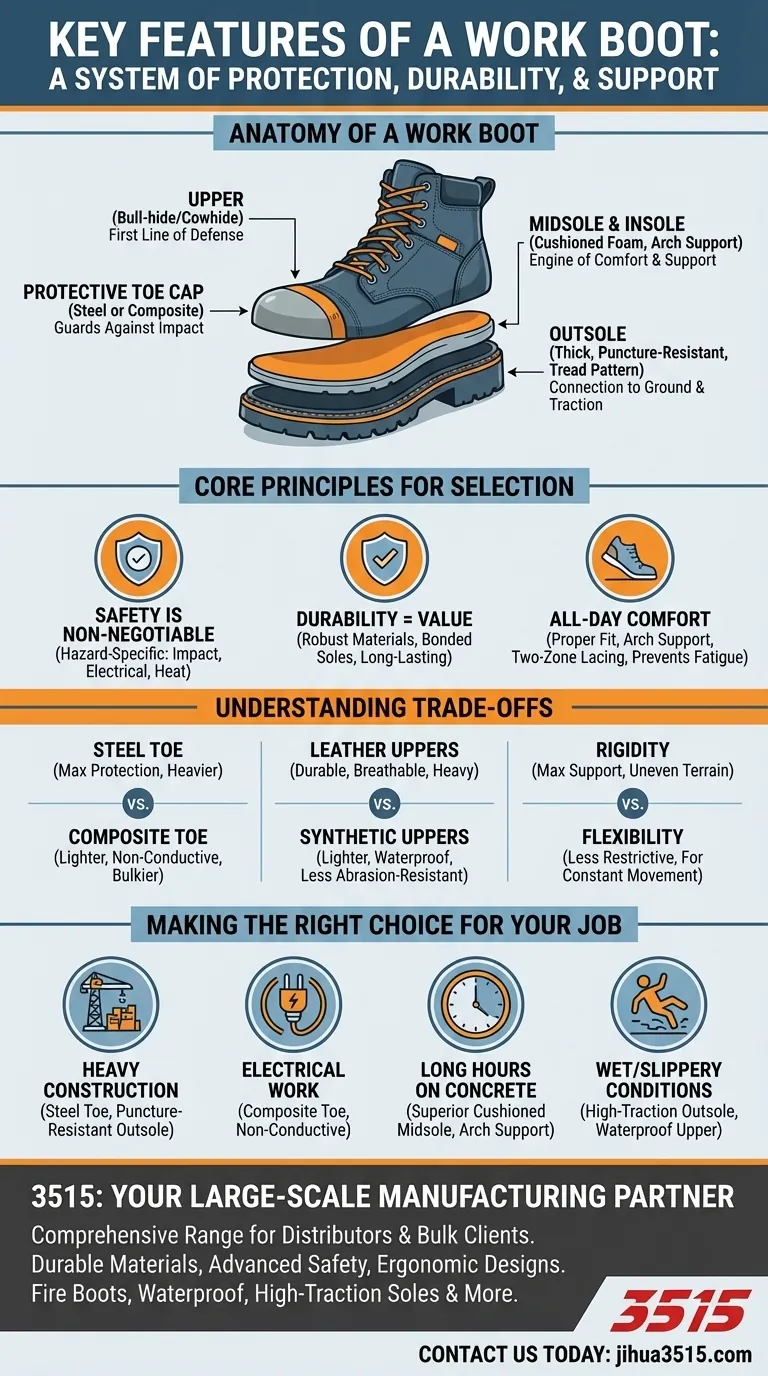

The Anatomy of a Work Boot: A System of Layers

Understanding how a work boot is constructed is the first step in appreciating its function. Each component serves a distinct purpose, working together to provide safety and comfort.

The Upper: Your First Line of Defense

The upper is the part of the boot that covers your foot. It is most often made from thick, durable leather, such as bull-hide or cowhide, which provides excellent resistance to abrasion and punctures.

The Protective Toe Cap: Guarding Against Impact

This is the most recognized safety feature. A reinforced toe cap protects against crushing and impact injuries from falling objects. The choice between a steel toe and a composite toe often depends on your specific job requirements.

The Outsole: Your Connection to the Ground

The outsole is the bottom layer that makes direct contact with surfaces. It must be made from a thick, durable material to resist punctures from sharp objects like nails. Equally important is its tread pattern, which provides traction and a solid grip to prevent slips and falls.

The Midsole and Insole: The Engine of Comfort and Support

Sandwiched between the outsole and your foot, the midsole provides cushioning and absorbs shock. The insole sits directly beneath your foot, offering arch support and improving the overall fit. Together, these components are critical for preventing fatigue during long days.

Core Principles for Selecting the Right Boot

Beyond the individual parts, several guiding principles should inform your decision. These concepts ensure the boot functions effectively as a piece of personal protective equipment.

Safety is Non-Negotiable

The primary purpose of a work boot is to prevent injury. Your choice must be dictated by the specific hazards of your job, whether that's impact, electrical risk, or extreme heat, as is the case for specialized fire boots.

Durability Translates to Value

A well-made boot with robust materials and construction will last longer, providing a better return on your investment. Look for features like high-quality leather and strongly bonded or stitched soles.

All-Day Comfort Prevents Fatigue

A boot that doesn't fit correctly is a constant distraction and can lead to long-term foot problems. Proper fit means about a half-inch of room for your toes, a snug heel that doesn't slip, and adequate arch support. Advanced features like two-zone lacing can also enhance comfort by allowing for a customized fit.

Understanding the Trade-offs

Choosing a work boot always involves balancing competing features. Recognizing these trade-offs is key to selecting the ideal boot for your needs.

Steel Toe vs. Composite Toe

Steel toes offer maximum impact protection but are heavier and conduct heat and cold. Composite toes are lighter, do not conduct electricity or temperature, but can be slightly bulkier to achieve the same safety rating.

Leather vs. Synthetic Uppers

Traditional leather uppers are exceptionally durable and breathable but can be heavy and require maintenance. Synthetic fabrics are often lighter and may offer better waterproofing out of the box, but can be less resistant to abrasion over time.

Rigidity vs. Flexibility

A highly rigid boot provides maximum ankle support and protection, which is ideal for uneven terrain. However, that same rigidity can feel restrictive and cause fatigue in jobs that require constant kneeling or climbing.

Making the Right Choice for Your Job

Your final decision should be dictated by your daily tasks and work environment. Match the boot's features to the demands of your job.

- If your primary focus is heavy construction or demolition: Prioritize maximum protection with a steel toe and a thick, puncture-resistant outsole.

- If your primary focus is electrical work or airport security: Choose a composite toe to avoid conductivity and meet metal-detector requirements.

- If your primary focus is long hours on concrete floors: Emphasize a boot with a superior cushioned midsole and proper arch support to combat fatigue.

- If your primary focus is working in wet or slippery conditions: Ensure the outsole is rated for high traction and consider a boot with a waterproof upper.

Ultimately, the best work boot is the one that allows you to focus on your job, confident that your feet are protected and supported.

Summary Table:

| Key Feature | Purpose | Common Materials/Examples |

|---|---|---|

| Protective Toe Cap | Guards against impact and crushing injuries | Steel toe, Composite toe |

| Upper Material | First line of defense against abrasions and punctures | Bull-hide, Cowhide leather |

| Outsole | Provides traction and puncture resistance | Thick rubber with deep treads |

| Midsole/Insole | Absorbs shock and provides arch support | Cushioned foam, Arch support systems |

| Safety Standards | Meets specific job hazard requirements | Electrical hazard, Puncture-resistant |

Ready to equip your workforce with superior safety footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of work boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety footwear, from steel-toe boots for heavy construction to composite-toe models for electrical work.

We combine durable materials, advanced safety features, and ergonomic designs to create boots that protect workers and prevent fatigue. Whether you need specialized fire boots, waterproof models, or high-traction soles, we have the manufacturing expertise to meet your specific requirements.

Contact 3515 today to discuss your work boot needs and discover how our manufacturing solutions can enhance your product line and protect your customers.

Visual Guide

Related Products

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What safety standards should oilfield work boots meet? Ensure OSHA & ASTM F2413 Compliance

- What are the benefits of steel toe caps in work boots? Achieve Maximum Protection for Heavy-Duty Work

- Why is specialized personal protective equipment required for specific industries? Enhancing Safety in Heavy Industry

- Why are industrial safety shoes necessary for mining machinery maintenance? Protect Feet from Crushing and Punctures

- What safety standards does the 11-inch waterproof pull-on boot meet? ASTM-Certified Protection for Industrial Work