The primary types of safety toe boots are defined by the material used in the protective cap: steel, composite, and alloy. Each offers a distinct combination of protection, weight, and environmental resistance tailored to different job requirements.

Choosing the right safety boot isn't about finding the "strongest" one, but about matching the specific properties of the toe material and boot style to the unique hazards and demands of your workplace.

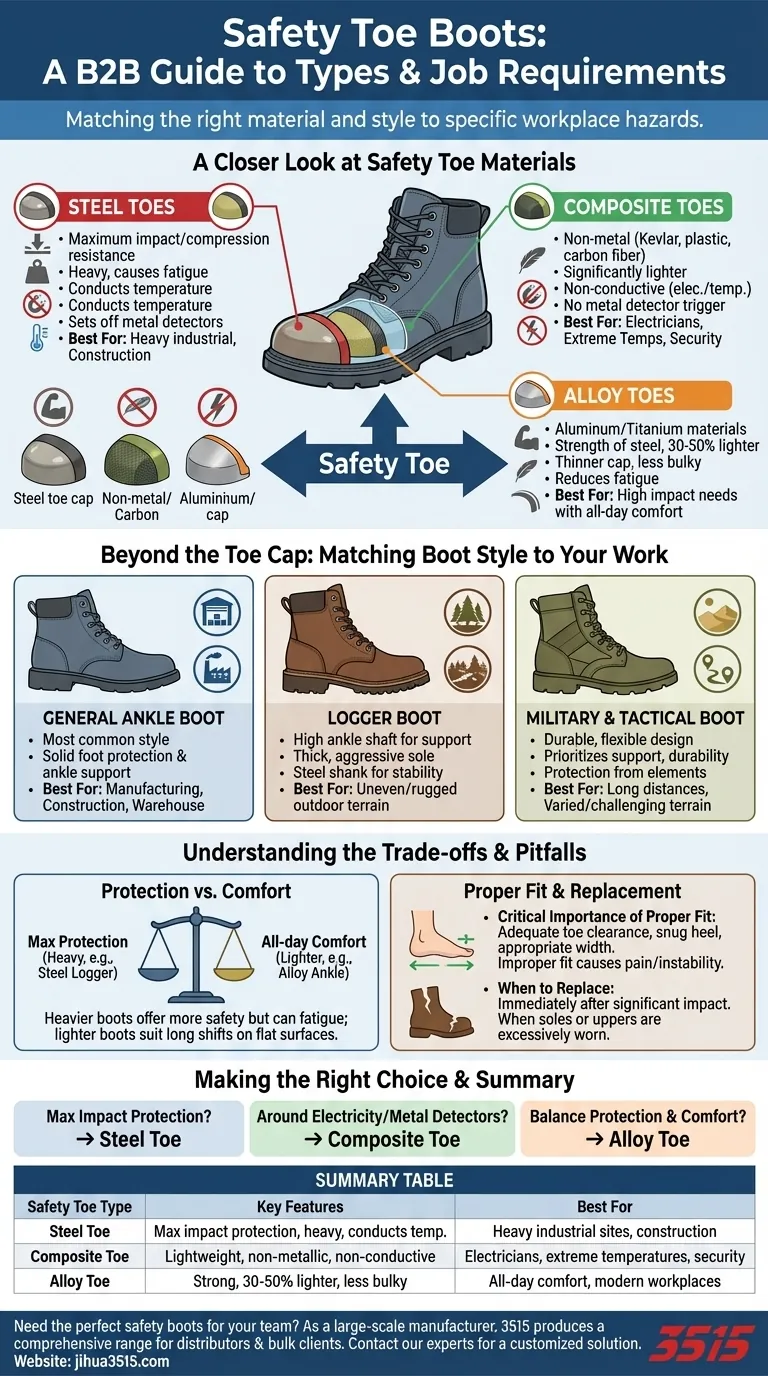

A Closer Look at Safety Toe Materials

The protective toe cap is the core safety feature. Understanding the fundamental differences between the materials is the first step in making an informed decision.

Steel Toes: The Original Standard

Steel toes have long been the industry benchmark for impact and compression resistance. They provide the maximum level of protection against heavy falling objects.

However, steel is heavy, which can lead to fatigue over a long workday. It also readily conducts temperature, making it feel cold in winter, and it will set off metal detectors.

Composite Toes: The Lightweight Alternative

Composite toes are made from non-metal materials like Kevlar, carbon fiber, or plastic. Their primary advantage is being significantly lighter than steel.

Because they contain no metal, they do not conduct electricity or temperature, making them ideal for electricians or those working in extreme cold or heat. They also won't trigger metal detectors. While strong, they can be slightly bulkier than steel to achieve a similar safety rating.

Alloy Toes: The Modern Hybrid

Alloy toes, typically made from materials like aluminum or titanium, offer a modern compromise. They provide the strength and protection of steel but are 30-50% lighter.

This makes them an excellent choice for those who need high impact resistance without the fatigue associated with steel toes. They are often thinner than composite caps, resulting in a more comfortable, less bulky fit in the toe box.

Beyond the Toe Cap: Matching Boot Style to Your Work

The safety toe is just one component. The overall design of the boot must match your work environment for true safety and stability.

General Ankle Boots

This is the most common style, seen in manufacturing, construction, and warehouse settings. It provides a solid balance of foot protection and ankle support for general-purpose work.

Logger Boots

Designed for uneven and rugged outdoor terrain, logger boots feature a much higher ankle shaft for maximum support. They also have a thick, aggressive sole and often a steel shank for stability when climbing or navigating difficult ground.

Military & Tactical Boots

Built for performance in harsh conditions, these boots prioritize ankle support, durability, and protection from the elements. They are designed for those covering long distances on foot over varied and challenging terrain.

Understanding the Trade-offs and Common Pitfalls

Selecting the wrong boot can compromise safety and cause significant discomfort. Awareness of the key trade-offs is crucial.

Protection vs. Comfort

The core trade-off often comes down to maximum protection versus all-day comfort. Heavier steel-toe logger boots offer incredible safety but can be fatiguing, whereas a lighter alloy-toe ankle boot may be more suitable for long shifts on concrete floors.

The Critical Importance of Proper Fit

A boot that doesn't fit correctly is a safety hazard. Ensure there is adequate toe clearance, your heel fits snugly without slipping, and the width is appropriate for your foot. An improper fit can lead to blisters, pain, and instability.

When to Replace Your Boots

Safety toe boots should be replaced immediately after any significant impact event, as the protective cap's structural integrity may be compromised. They should also be replaced when the soles or uppers become excessively worn, as this reduces support and slip resistance.

Making the Right Choice for Your Job

Your specific work environment and daily tasks should be the ultimate guide for your selection.

- If your primary focus is maximum impact protection in heavy industrial or construction sites: A steel toe boot provides the highest, time-tested level of safety.

- If your primary focus is working around electricity or metal detectors: A composite toe is the essential choice for its non-conductive, metal-free properties.

- If your primary focus is balancing strong protection with all-day comfort: An alloy toe offers a lightweight yet highly protective solution ideal for many modern workplaces.

Ultimately, the best safety boot is the one that correctly addresses the specific risks you face every day.

Summary Table:

| Safety Toe Type | Key Features | Best For |

|---|---|---|

| Steel Toe | Maximum impact protection, heavy, conducts temperature | Heavy industrial sites, construction |

| Composite Toe | Lightweight, non-metallic, non-conductive | Electricians, extreme temperatures, security checks |

| Alloy Toe | Strong protection, 30-50% lighter than steel, less bulky | All-day comfort, modern workplaces requiring high safety |

Need the perfect safety boots for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety toe boots—from steel and composite to alloy—ensuring your workforce has the right protection, comfort, and durability for their specific job requirements.

Contact our experts today for a customized solution that meets your safety standards and operational needs.

Visual Guide

Related Products

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What are the general care precautions for all types of work footwear? Protect Your Investment & Safety

- What is the current safety footwear standard in Europe? Your Guide to EN ISO 20345

- What is the significance of using ergonomic protective footwear to mitigate legal disputes? Shield Your Business Now

- What are the slip resistance requirements for safety boots? Professional Grip Standards for Poultry Facility Cleaning

- Why is centralized procurement management necessary for specialty protective shoes? Maximize Safety and Cost Efficiency

- What type of safety boots are suitable for an oil construction worker? Essential Features for Hazardous Sites

- How does vegan leather compare to genuine leather in work shoes? Choose the Right Material for Your Job

- Why is strict compliance with standards like CNS 20345 essential for safety shoe production? Ensure Industrial Safety