At its core, a high-quality oilfield boot is a system of specialized materials working in concert. The most common components include durable uppers made from full-grain or abrasion-resistant leather, advanced outsoles of rubber or thermoplastic polyurethane (TPU), and climate-control linings like waterproof membranes and Thinsulate insulation.

The selection of materials in an oilfield boot is a deliberate engineering choice. It's not about finding one "best" material, but about creating a balanced system that provides maximum protection, slip resistance, and durability without sacrificing the all-day comfort required for demanding work.

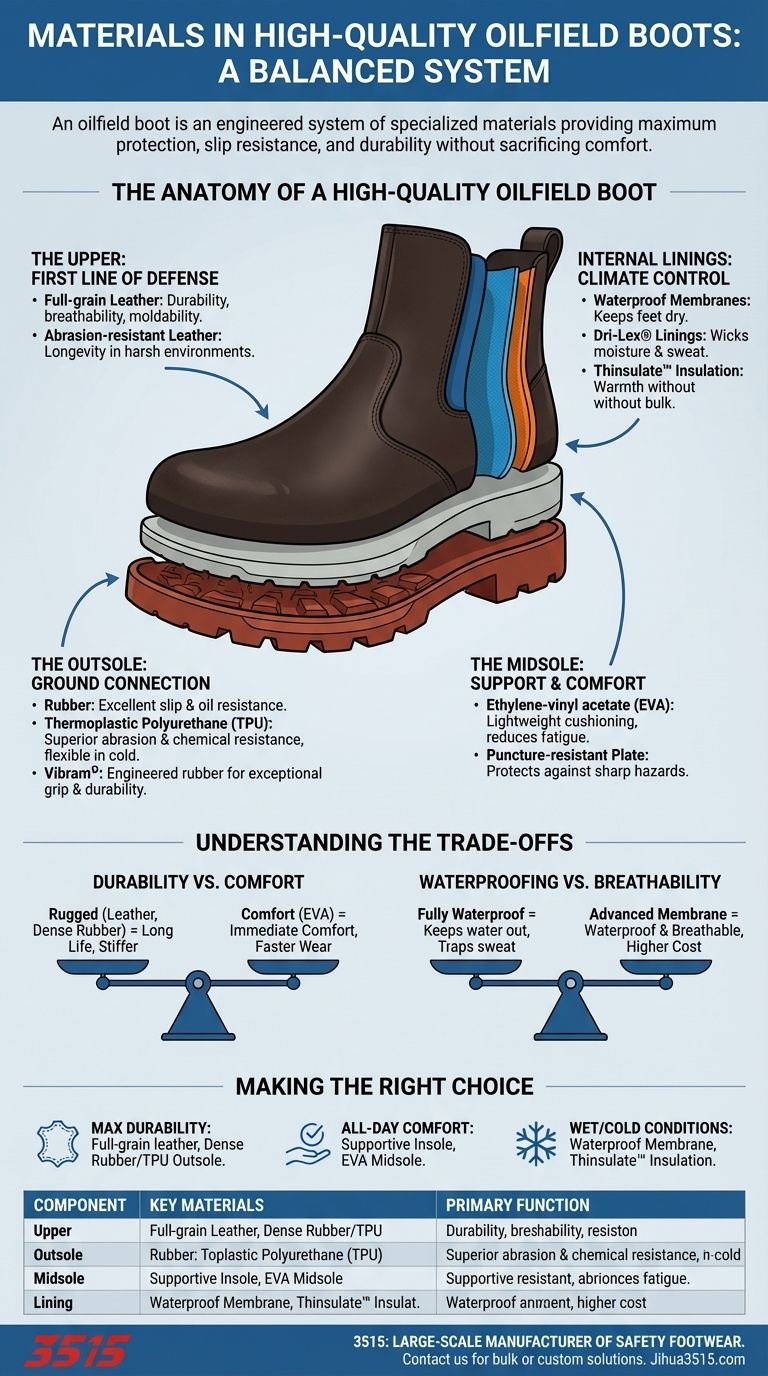

The Anatomy of a High-Quality Oilfield Boot

Understanding a boot requires looking at its individual components. Each material is chosen to solve a specific problem encountered in the field, from chemical exposure to extreme weather.

The Upper: Your First Line of Defense

The upper is the main body of the boot that covers your foot. Its primary job is to provide durable protection against impacts, abrasions, and chemical splashes.

Full-grain leather is the gold standard for its exceptional durability, breathability, and ability to mold to the wearer's foot over time. Some boots use specially treated, abrasion-resistant leathers for even greater longevity in harsh environments.

The Outsole: Your Connection to the Ground

The outsole is arguably the most critical safety component of an oilfield boot. It must provide steadfast grip on surfaces contaminated with oil, water, and mud while resisting degradation from chemicals.

- Rubber is the traditional, widely used material known for its excellent slip and oil resistance.

- Thermoplastic Polyurethane (TPU) is a modern polymer that offers superior resistance to abrasion, oils, and chemicals while remaining flexible in cold temperatures.

- Vibram® is not a material but a leading brand of outsole, typically made from a high-performance vulcanized rubber compound engineered for exceptional grip and durability.

The Midsole: The Foundation of Support

Sandwiched between the outsole and your foot, the midsole provides cushioning and absorbs shock, reducing fatigue during long shifts.

Ethylene-vinyl acetate (EVA) is a common midsole material. It is a lightweight foam that provides excellent comfort and toughness, making boots feel more athletic and less cumbersome.

Many oilfield boots also integrate a puncture-resistant plate within the sole construction, protecting the foot from nails, scrap metal, and other sharp hazards on the worksite.

Internal Linings: Managing the Interior Climate

The inside of the boot is just as important as the outside. Linings are chosen to manage moisture, temperature, and overall comfort.

- Waterproof membranes are essential for keeping feet dry from external elements like rain, puddles, and mud.

- Dri-Lex® linings are designed to wick moisture and sweat away from the foot, keeping it dry and preventing blisters.

- Thinsulate™ insulation provides warmth in cold working conditions without adding significant bulk or weight to the boot.

Understanding the Trade-offs

No single boot excels at everything. Choosing the right one involves understanding the inherent compromises between different materials and designs.

Durability vs. Comfort

The most rugged materials, like thick leather and dense rubber outsoles, offer the longest service life. However, they are often heavier and stiffer, requiring a break-in period.

Conversely, boots designed for immediate comfort with lightweight EVA midsoles may wear down faster under the relentless stress of an oilfield environment.

Waterproofing vs. Breathability

A fully waterproof boot is excellent at keeping water out, but it can also trap sweat inside, leading to discomfort.

High-end boots use advanced membranes that are both waterproof and breathable, allowing water vapor (sweat) to escape while blocking liquid water from entering. This technology, however, adds to the cost.

Making the Right Choice for Your Needs

Selecting the right boot depends entirely on your specific job function, environment, and physical needs.

- If your primary focus is maximum durability and chemical resistance: Look for boots with full-grain leather uppers and a dense rubber or TPU outsole.

- If your primary focus is all-day comfort and reduced fatigue: Prioritize a boot with a supportive insole and an EVA midsole for superior shock absorption.

- If your primary focus is working in wet or cold conditions: A certified waterproof membrane is non-negotiable, and the level of Thinsulate insulation should match your climate.

Understanding these core materials transforms your choice from a simple purchase into an informed decision about a critical piece of safety equipment.

Summary Table:

| Component | Key Materials | Primary Function |

|---|---|---|

| Upper | Full-grain leather, Abrasion-resistant leather | Impact, abrasion, and chemical protection |

| Outsole | Rubber, Thermoplastic Polyurethane (TPU) | Slip, oil, and chemical resistance |

| Midsole | Ethylene-vinyl acetate (EVA), Puncture-resistant plate | Shock absorption, foot support |

| Lining | Waterproof membranes, Dri-Lex®, Thinsulate™ | Moisture management, temperature control |

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our expertise in engineering oilfield boots with the right material balance—from durable leather uppers to advanced TPU outsoles—ensures maximum protection, comfort, and value for your workforce. Contact us today to discuss your custom or bulk footwear needs!

Visual Guide

Related Products

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

People Also Ask

- What are firefighter boots and what are they designed for? Essential Protection for First Responders

- Can work boots be cleaned in a washing machine? Avoid Damage and Extend Boot Life

- How have synthetic materials influenced the design of Western boots? Boost Performance & Safety

- What comfort features are incorporated into Western work boots? All-Day Support for Demanding Work

- What are the advantages of ankle-high lace-up boots? Superior Support & Style for Work & Office

- What is the significance of safety training with safety boots? Maximizing Protection in High-Risk Zones

- Can insulated boots cause feet to sweat? How to ensure dry warmth with the right materials.

- How does rebuildability extend the life of fire boots? Maximize Your Gear's Lifespan & ROI