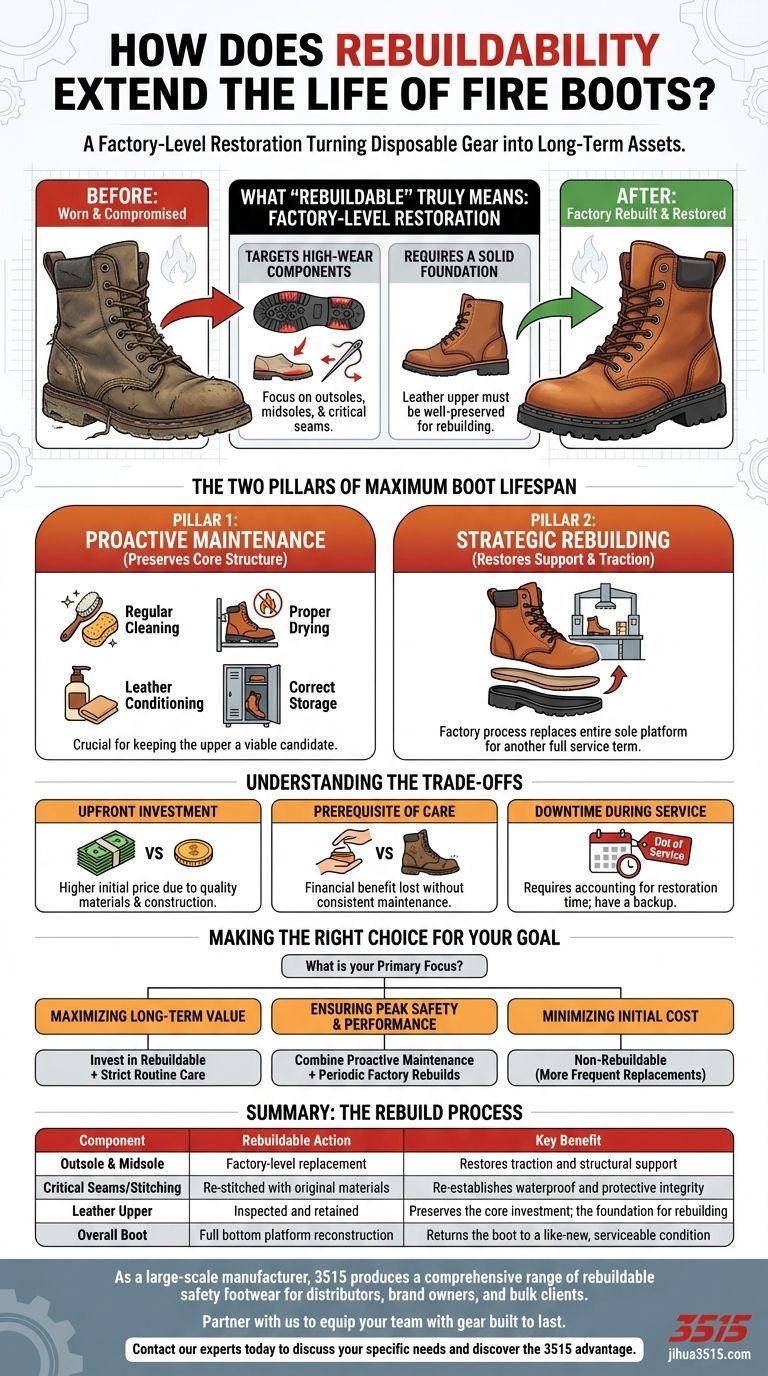

In short, rebuildability extends the life of fire boots by allowing critical high-wear components, like the soles and stitching, to be completely replaced by the manufacturer. This process restores the boot to a like-new condition, turning a disposable piece of equipment into a long-term, serviceable asset and maximizing the initial investment.

Rebuildability is not merely a repair; it is a strategic feature that fundamentally changes a boot's lifecycle. However, its value is only realized when the core leather structure is preserved through consistent, routine care.

What "Rebuildable" Truly Means

The concept of rebuilding goes far beyond what a local cobbler can offer. It is a factory-level restoration process designed to address the specific, intense wear that fire boots endure.

Targeting High-Wear Components

The most common failure points on a fire boot are the parts that face constant friction, heat, and stress. Rebuilding specifically targets these areas, primarily the outsoles, midsoles, and critical seams.

A Factory-Level Restoration

When a boot is rebuilt, it's sent back to the original manufacturer or an authorized specialist. They strip away the worn-out sole assembly and any compromised stitching, inspect the foundational leather upper, and then construct a new "bottom" for the boot using original materials and machinery.

The Foundation Must Be Solid

This process is only possible if the leather upper—the main body of the boot—is in good condition. Rebuilding cannot fix leather that is cracked, dried out, or damaged from neglect. The durability of the upper determines the boot's ultimate potential for being rebuilt.

The Two Pillars of Maximum Boot Lifespan

Thinking of rebuildability as a magic bullet is a mistake. To truly maximize a fire boot's service life, you must combine this powerful restoration option with disciplined, proactive maintenance.

Pillar 1: Proactive Maintenance

This is the daily and weekly care that preserves the boot's core structure, making it a viable candidate for a future rebuild.

- Regular Cleaning: Removing dirt, soot, and chemical contaminants prevents the degradation of leather and synthetic materials.

- Proper Drying: Boots must be dried slowly and away from direct heat. Extreme temperatures can cause leather to shrink and crack, compromising its integrity permanently.

- Leather Conditioning: Applying a quality conditioner keeps the leather supple and prevents it from drying out, which is the most common reason a boot cannot be rebuilt.

- Correct Storage: Storing boots in a cool, dry place helps maintain their shape and material stability over time.

Pillar 2: Strategic Rebuilding

This is the long-term fix you execute when proactive care is no longer enough to address the wear on the soles and seams. By replacing the entire sole platform, you restore the boot's essential support, traction, and protective qualities for another full term of service.

Understanding the Trade-offs

While highly effective, the rebuildable model is not without its considerations. It requires a shift in how you view and manage your equipment.

The Upfront Investment

Boots constructed to be rebuildable are often made with higher-quality materials and more robust construction methods, such as Goodyear welting. This typically results in a higher initial purchase price compared to disposable, cemented-sole boots.

The Prerequisite of Care

The financial benefit of rebuilding is completely lost if the boot's upper is not maintained. A department that invests in rebuildable boots without implementing a parallel care and maintenance program will not see a return on that investment.

Downtime During Service

The rebuilding process is not instantaneous. You must account for the time the boots will be out of service while at the factory for restoration. This often requires having a backup pair available.

Making the Right Choice for Your Goal

- If your primary focus is maximizing long-term value: Invest in a quality rebuildable boot and implement a strict routine care program to preserve the leather upper.

- If your primary focus is ensuring peak safety and performance: Combine proactive maintenance with periodic factory rebuilds to maintain the boot's structural integrity and protective qualities.

- If your primary focus is minimizing initial cost: Recognize that non-rebuildable boots, while cheaper upfront, will require more frequent and complete replacements over their service life.

Ultimately, a rebuildable fire boot, when properly cared for, transforms a recurring equipment expense into a career-long asset.

Summary Table:

| Component | Rebuildable Action | Key Benefit |

|---|---|---|

| Outsole & Midsole | Factory-level replacement | Restores traction and structural support |

| Critical Seams/Stitching | Re-stitched with original materials | Re-establishes waterproof and protective integrity |

| Leather Upper | Inspected and retained | Preserves the core investment; the foundation for rebuilding |

| Overall Boot | Full bottom platform reconstruction | Returns the boot to a like-new, serviceable condition |

As a large-scale manufacturer, 3515 produces a comprehensive range of rebuildable safety footwear for distributors, brand owners, and bulk clients.

We understand that your investment in safety gear is critical. Our production capabilities encompass all types of durable, rebuildable shoes and boots designed for maximum lifespan and return on investment.

Partner with us to equip your team with gear built to last. Contact our experts today to discuss your specific needs and discover the 3515 advantage.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- Which brands are known for high-quality work boots? A Guide to Durable, Safe Footwear

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What are the requirements for compression resistance in safety toe boots? Ensure OSHA & ASTM F2413 Compliance

- What should you check for when testing the fit of new work boots? Ensure All-Day Comfort and Safety

- Why are work boots considered essential PPE? Unlock Superior Foot Protection for Your Workforce

- What features should be considered when choosing work boots for women? Essential Guide for Safety & Comfort

- What are the characteristics of wedge sole work boots? Ultimate Comfort for Hard Floors

- How often should a protective agent be reapplied to work boots? Maximize Boot Life & Performance