As a general rule, work boots should not be cleaned in a washing machine. The combination of intense, prolonged water submersion, aggressive tumbling, and harsh detergents can irreversibly damage the materials, compromise structural integrity, and ruin protective features like waterproofing. The weight and rigidity of the boots can also damage the washing machine itself.

The core issue is control. A washing machine is a blunt instrument that subjects boots to damaging forces and saturation. Proper manual cleaning allows you to use the right techniques for specific materials, preserving the boot's function and lifespan.

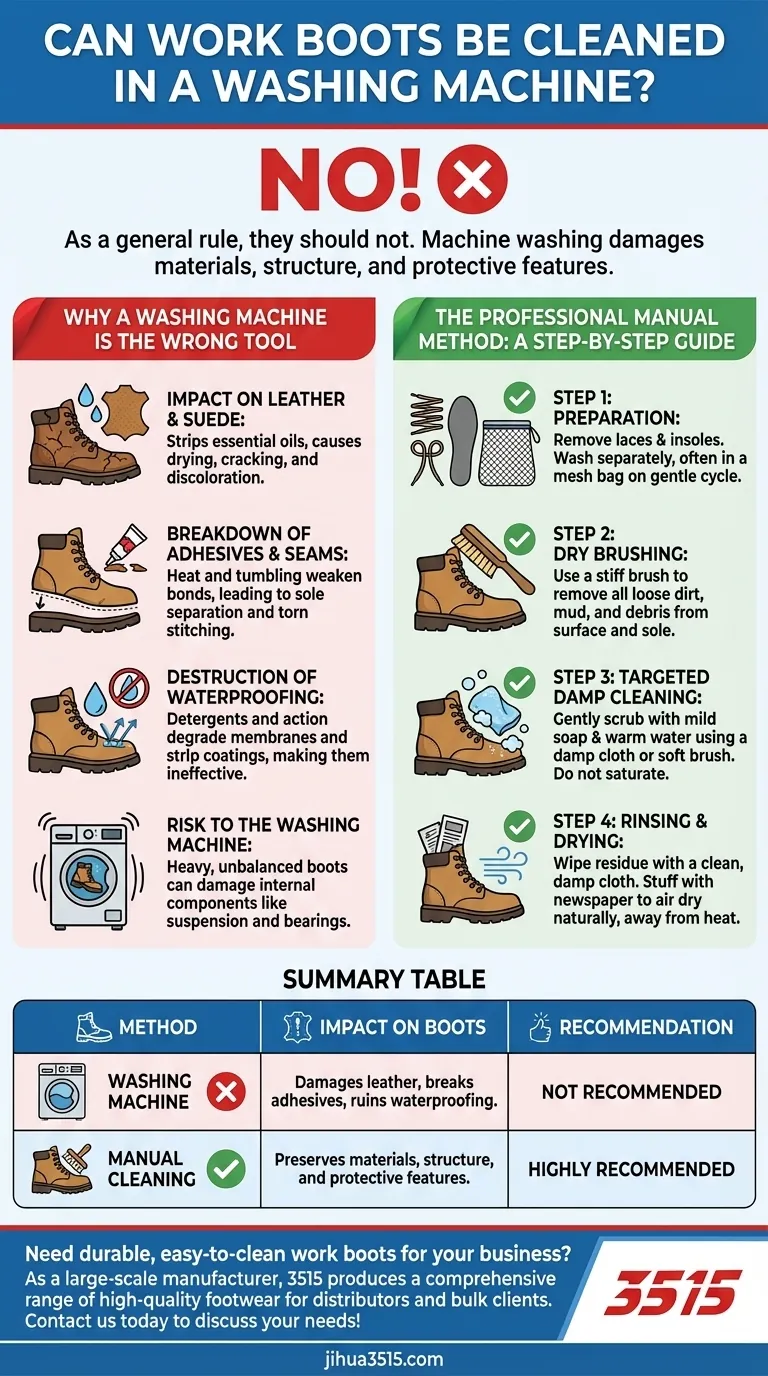

Why a Washing Machine Is the Wrong Tool for the Job

A washing machine's cycle is fundamentally incompatible with the construction and materials of a quality work boot. Understanding the specific points of failure makes the case for manual cleaning clear.

The Impact on Leather and Suede

Leather is a natural skin that contains essential oils. Submerging it in water and agitating it strips these oils away, causing the leather to become dry, brittle, and prone to cracking once it dries. Suede and nubuck are even more delicate and can be permanently discolored or have their texture ruined.

The Breakdown of Adhesives and Seams

Modern work boots rely on powerful adhesives to bond the sole to the upper part of the boot. The combination of heat and forceful tumbling in a wash cycle can weaken these bonds, leading to sole separation. Stitching can also be stretched or torn.

The Destruction of Waterproofing

Many work boots feature a waterproof membrane or have been treated with a water-repellent coating. The harsh detergents and mechanical action of a washing machine can degrade these membranes and strip away the coatings, rendering the waterproofing ineffective.

The Risk to the Washing Machine

Heavy work boots, especially steel-toed models, can throw a washing machine's drum off balance. This can cause violent shaking that may damage the machine's internal components, such as the suspension or bearings.

The Professional Method: A Step-by-Step Guide to Manual Cleaning

Proper cleaning isn't just about aesthetics; it's essential maintenance that extends the life of your investment.

Step 1: Preparation

First, remove the laces and insoles from your boots. These can often be washed separately, either by hand or in the washing machine inside a mesh laundry bag on a gentle cycle.

Step 2: Dry Brushing

Use a stiff-bristled boot brush to remove all loose dirt, mud, and debris from the boot's surface and sole. Pay close attention to the seams and crevices where dirt accumulates. This step is crucial and should always be done first.

Step 3: Targeted Damp Cleaning

Mix a small amount of mild soap (like saddle soap for leather or a specialized boot cleaner) with warm water. Dampen a cloth or soft brush in the solution—do not saturate it—and gently scrub the boot's surface in small, circular motions.

Step 4: Rinsing and Drying

Wipe away any soap residue with a separate, clean, damp cloth. Never rinse the boots under running water. To dry, stuff them with newspaper or paper towels to absorb internal moisture and help them keep their shape. Let them air dry naturally, away from direct sunlight or heat sources like vents, which can crack the material.

Making the Right Choice for Your Boots

Your approach should be tailored to preserving the specific materials and features of your work boots.

- If your primary focus is preserving leather or suede: Manual cleaning with material-specific products like saddle soap is the only safe option to prevent drying and cracking.

- If your primary focus is maintaining waterproofing: Avoid machine washing at all costs, as it will strip away protective coatings and damage waterproof membranes.

- If your primary focus is the boot's structural longevity: Hand-washing is essential to protect the adhesives and stitching that hold the boot together.

Ultimately, taking the time to clean your work boots correctly is a critical part of ensuring they continue to protect you on the job.

Summary Table:

| Cleaning Method | Impact on Boots | Recommendation |

|---|---|---|

| Washing Machine | Damages leather, breaks adhesives, ruins waterproofing | Not Recommended |

| Manual Cleaning | Preserves materials, structure, and protective features | Highly Recommended |

Need durable, easy-to-clean work boots for your business? As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality footwear for distributors, brand owners, and bulk clients. Our expertise ensures your boots are built to last and easy to maintain. Contact us today to discuss your footwear needs and benefit from our extensive production capabilities!

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

- Premium Oil Wax Leather Safety Boots for Bulk Purchase

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

People Also Ask

- What protective functions do industrial safety shoes provide for utility technicians? Stability & Electrical Insulation

- What are the OSHA recommendations for wearing protective footwear? A Legal Guide to Workplace Foot Safety

- What are the core safety features of industrial safety shoes? Expert Guide for Bridge & Heavy Machinery Safety

- What are the requirements for oilfield boots? Essential Safety & Durability Features

- What is the difference between side-zip and lace-up security guard safety boots? Speed vs. Perfect Fit