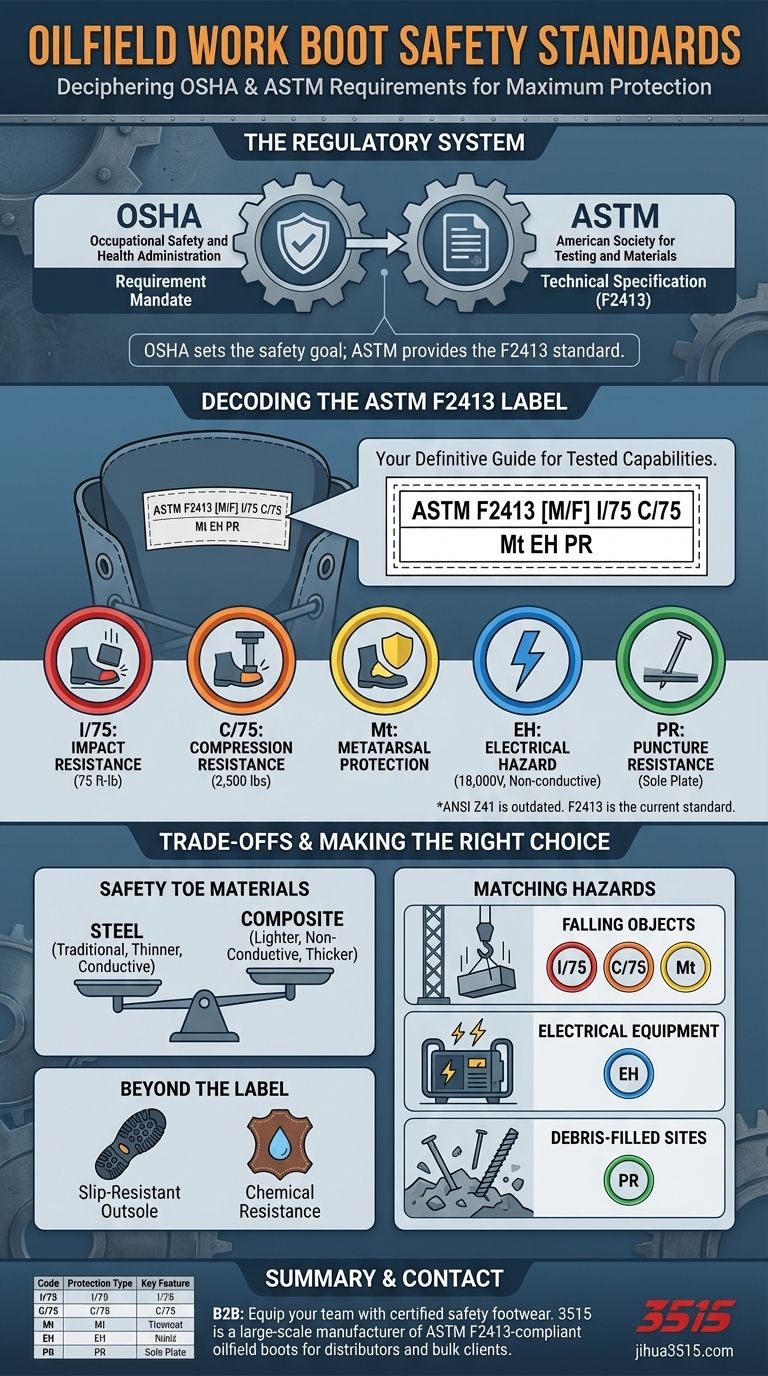

In short, oilfield work boots must meet the performance requirements outlined in the ASTM F2413 standard, which is the benchmark recognized by the Occupational Safety and Health Administration (OSHA). This standard specifies the minimum requirements for design, performance, testing, and classification of protective footwear. A compliant boot will have a label inside detailing the exact types of protection it offers.

The critical takeaway is that "OSHA-approved" is a general requirement, but the specific ASTM F2413 label inside the boot is your definitive guide. Learning to read this label allows you to match the boot's tested capabilities to the specific hazards of your job site, from impact protection to electrical shock resistance.

Deconstructing the Safety Standards

To truly understand what makes a boot safe, you need to know the organizations behind the acronyms and the roles they play. They work together as a system to ensure your footwear provides proven protection.

OSHA's Role: The Requirement

The Occupational Safety and Health Administration (OSHA) is a government agency that sets and enforces workplace safety regulations. OSHA mandates that employers protect workers from foot injuries, but it does not write the specific technical standards for the boots themselves. Instead, it defers to consensus standards developed by expert organizations.

ASTM's Role: The Technical Specification

The American Society for Testing and Materials (ASTM) develops the technical standards. ASTM F2413 is the current, active standard for protective footwear in the United States. It outlines the precise testing methods and performance criteria boots must meet for features like toe protection, puncture resistance, and more.

What About ANSI?

You may see references to the American National Standards Institute (ANSI). The older ANSI Z41 standard was replaced by the ASTM F2413 standard in 2005. Any modern, compliant work boot will be certified to the ASTM standard, not the outdated ANSI one.

Decoding the ASTM F2413 Label

The most important information is printed on a label sewn inside the boot, typically on or near the tongue. This label is a clear, concise summary of the boot's protective features.

The Essential Two Lines

The label is typically formatted into two or more lines. The first line identifies the standard (ASTM F2413) and the gender for which the boot was designed (M/F). The subsequent lines list the specific safety features.

Line 1: Impact and Compression

This line always details the protection for the toe area.

- I/75: This indicates the boot meets the highest standard for Impact resistance, protecting your toes from a 75-foot-pound impact.

- C/75: This indicates the boot meets the highest standard for Compression resistance, protecting your toes from a compressive load of up to 2,500 pounds.

Line 2: Hazard-Specific Protection

This line uses codes to specify additional protections, which are critical in a varied environment like an oilfield.

- Mt: Metatarsal protection guards the top of your foot from impact.

- EH: Electrical Hazard protection means the sole and heel are made from non-conductive materials that can withstand 18,000 volts at 60 Hz for one minute with no leakage.

- PR: Puncture Resistant footwear includes a plate inside the sole to prevent sharp objects like nails from penetrating the bottom of the boot.

Understanding the Trade-offs

Meeting the standard is the baseline, but the materials and construction used to achieve it involve important trade-offs you should consider.

Safety Toe Materials: Steel vs. Composite

Both steel and composite toes can meet the same I/75 C/75 rating. The primary difference is in material properties. Steel toes are traditional and can be made thinner, while composite toes (made of materials like carbon fiber or Kevlar) are lighter and do not conduct heat, cold, or electricity.

Beyond the Label: Sole and Material Quality

The ASTM standard verifies specific, testable hazards. It does not, however, guarantee a boot's overall durability or its performance on all surfaces. Look for high-quality leather for chemical resistance and an aggressively lugged, slip-resistant outsole, as slips and falls are a major risk on oil rigs.

The Importance of Third-Party Certification

To receive an ASTM certification, a boot must be tested by an independent, third-party laboratory. This ensures that the manufacturer's claims are verified by an unbiased source, providing true confidence that the boot will perform as specified.

Making the Right Choice for Your Oilfield Role

Your specific job function determines which safety features are most critical. Use the ASTM label to find the right tool for the job.

- If your primary focus is protection from falling objects: Ensure the boot is rated I/75 and C/75, and strongly consider an Mt (Metatarsal) rating for added protection.

- If your primary focus is working near generators or electrical equipment: The EH (Electrical Hazard) rating is a non-negotiable requirement to protect against accidental shock.

- If your primary focus is navigating debris-filled sites: A PR (Puncture Resistant) rating is essential to protect the bottom of your feet from nails, rebar, and other sharp hazards.

By understanding the codes on the label, you can confidently select a boot engineered for the specific hazards you face every day.

Summary Table:

| ASTM F2413 Code | Protection Type | Key Feature |

|---|---|---|

| I/75 | Impact Resistance | Protects toes from 75-ft-lb impact |

| C/75 | Compression Resistance | Withstands 2,500 lbs of compression |

| Mt | Metatarsal Protection | Guards the top of the foot |

| EH | Electrical Hazard | Resists 18,000 volts, non-conductive |

| PR | Puncture Resistance | Prevents sharp object penetration |

Ensure your team is equipped with the right safety footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM F2413-compliant oilfield work boots for distributors, brand owners, and bulk clients. Our production capabilities ensure durable, hazard-specific boots that meet OSHA requirements. Contact us today for reliable, certified work boots tailored to your oilfield needs.

Visual Guide

Related Products

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Grain Leather Safety Boots for Bulk Supply

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- How long can work boots typically last with proper care? Maximize Your Investment's Lifespan

- How are ASTM standards verified for work boots? Ensuring Unbiased Safety with Third-Party Testing

- What are the key features of work boots for commercial fishing? Essential Safety & Durability Guide

- What are the characteristics of Vibram Red X soles? Designed for Extreme Heat & Rugged Terrain

- What is a recommended color for work boots? Discover the Best Choice for Durability & Professionalism

- What are the practical reasons for the popularity of cowboy boots as work attire? Unmatched Durability & Protection

- Why is hemp fiber considered an ideal reinforcement material? Discover the Lightweight Secret of High-Performance Boots

- What are the temperature ratings and recommended uses for 400g insulated boots? Your Guide to Winter Warmth