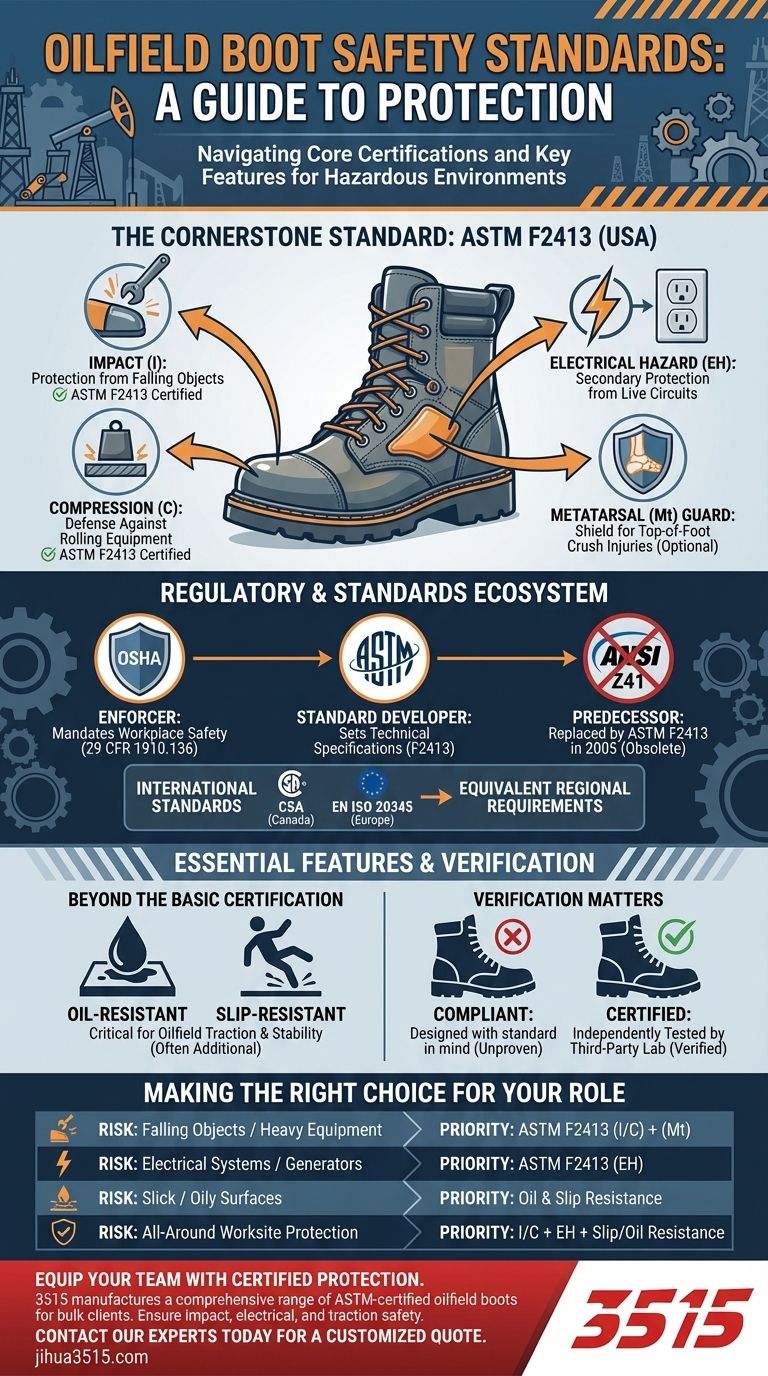

The cornerstone safety standard for oilfield boots in the United States is ASTM F2413. This single standard, which is referenced by the Occupational Safety and Health Administration (OSHA), sets the minimum performance requirements for protective footwear. It covers the most critical hazards, including impact to the toes from falling objects, compression from heavy equipment, and secondary protection from electrical currents.

Understanding safety standards is not about memorizing codes, but about recognizing what specific protections a boot has been third-party tested and certified to provide. These standards are your assurance that the footwear is engineered to defend against the predictable, high-risk hazards of the oilfield.

Deconstructing the Core Standard: ASTM F2413

The American Society for Testing and Materials (ASTM) provides the technical specifications that define what makes a work boot a true piece of safety equipment. The F2413 standard is the primary specification for protective footwear in the US.

The Foundation of Protection (I/C)

The most fundamental requirement under ASTM F2413 is Impact (I) and Compression (C) resistance for the toe area. This is achieved with a protective safety toe cap, typically made of steel, aluminum, or a composite material. This feature is non-negotiable for protecting against falling tools and rolling equipment.

Electrical Hazard (EH) Rating

The EH rating signifies that the boot's outsole and heel are constructed to provide secondary protection against accidental contact with live electrical circuits. This is a critical feature in any industrial environment where electrical equipment is present, reducing the potential for electric shock.

Metatarsal (Mt) Protection

Some boots certified under ASTM F2413 also include a metatarsal (Mt) guard. This component provides an additional layer of protection for the top of the foot (the metatarsal bones), which is vulnerable to crush injuries.

The Role of Regulatory and Standards Bodies

Multiple organizations are involved in the safety footwear ecosystem. Understanding their distinct roles clarifies why you see different names associated with boot safety.

OSHA: The Enforcer

The Occupational Safety and Health Administration (OSHA) is the government agency that mandates workplace safety. Under regulation 29 CFR 1910.136, OSHA requires employers to ensure their workers use protective footwear in hazardous environments. However, OSHA does not write the footwear standards itself; it relies on consensus standards developed by organizations like ASTM.

ANSI: The Predecessor

You may see older boots marked with ANSI Z41. The American National Standards Institute (ANSI) set the previous standard, but it was replaced by ASTM F2413 in 2005. Any new, certified protective footwear you purchase today should carry the ASTM rating.

International Standards (CSA & EN ISO)

For work outside the United States, you will encounter different standards. The Canadian Standards Association (CSA) sets the requirements for Canada, while the EN ISO 20345 standard is the equivalent for Europe. While their testing methods may differ slightly, they address the same core hazards.

Understanding Key Features and Verification

A safety rating is more than just a label inside the tongue of a boot. It represents a verified process and dictates the inclusion of specific protective features.

Beyond the Basic Certification

While ASTM F2413 covers the core safety requirements, oilfield work presents additional challenges. Look for boots with outsoles specifically designed to be oil-resistant and slip-resistant, as these are two of the most common causes of injury on a rig or worksite.

The Importance of Third-Party Testing

To receive a legitimate ASTM certification, footwear must be tested by an independent, third-party laboratory. This lab issues a Certificate of Conformance to verify that the boot meets or exceeds the specified standard. This process ensures the ratings are unbiased and reliable.

A Common Pitfall: "Compliant" vs. "Certified"

Be wary of vague terms. A boot that is "ASTM compliant" may simply be designed with the standard in mind. A boot that is "ASTM certified" has been independently tested and proven to meet the standard's rigorous performance benchmarks. Always look for official certification.

Making the Right Choice for Your Role

Selecting the proper boot requires matching its certified protections to the specific hazards you will face.

- If your primary risk is falling objects or heavy equipment: Prioritize a boot with a certified ASTM F2413 safety toe (I/C), and consider adding metatarsal (Mt) protection for comprehensive coverage.

- If you work near generators or electrical systems: Ensure your boot carries the ASTM F2413 EH rating for secondary electrical hazard protection.

- If you frequently encounter slick or oily surfaces: Look for boots specifically rated for oil and slip resistance, a critical feature that goes beyond the core ASTM impact standard.

- If you need all-around worksite protection: Seek a boot that combines all of these features—a certified ASTM F2413 safety toe and EH rating, plus a high-traction, oil-resistant outsole.

Ultimately, your safety boot is a critical piece of personal protective equipment, and its standards are the language that tells you exactly how it will perform.

Summary Table:

| Standard/Feature | Key Protection | Key Takeaway |

|---|---|---|

| ASTM F2413 (I/C) | Impact & Compression Toe | The foundational US standard for protecting against falling objects and heavy equipment. |

| ASTM F2413 (EH) | Electrical Hazard | Provides secondary protection against accidental contact with live electrical circuits. |

| ASTM F2413 (Mt) | Metatarsal Guard | Protects the top of the foot from crush injuries. |

| CSA / EN ISO 20345 | Regional Standards | Equivalent standards for work in Canada and Europe, respectively. |

| Oil & Slip Resistance | Traction & Stability | Critical features for oilfield environments, often specified beyond the core ASTM standard. |

Ensure your team is equipped with certified, reliable safety footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified oilfield boots for distributors, brand owners, and bulk clients. Our production capabilities ensure every pair meets the highest standards for impact resistance (I/C), electrical hazard protection (EH), and superior traction. Protect your workforce with boots built for the most demanding environments. Contact our experts today to discuss your specific needs and receive a customized quote.

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- What role do professional protective boots play in self-rescue scenarios during All-Terrain Vehicle (ATV) rollover accidents? Your Key to Survival & Escape

- What is Cement Construction in work boots? Unlocking the Secrets of Boot Durability & Comfort

- How did engineer boots evolve in postwar culture? From Workwear to Rebel Icon

- What future innovations are being explored for firefighting boots? Smart, Lightweight Designs for Enhanced Performance

- How do ergonomic designs enhance comfort in work boots? Boost All-Day Productivity & Reduce Fatigue

- What work boot features are essential for farming and agricultural work? Complete Protection Guide

- What should be considered when choosing PVC work boots? Select the Right Boot for Your Job Hazards

- What are oilfield boots designed for? Unmatched Protection for Rig Workers