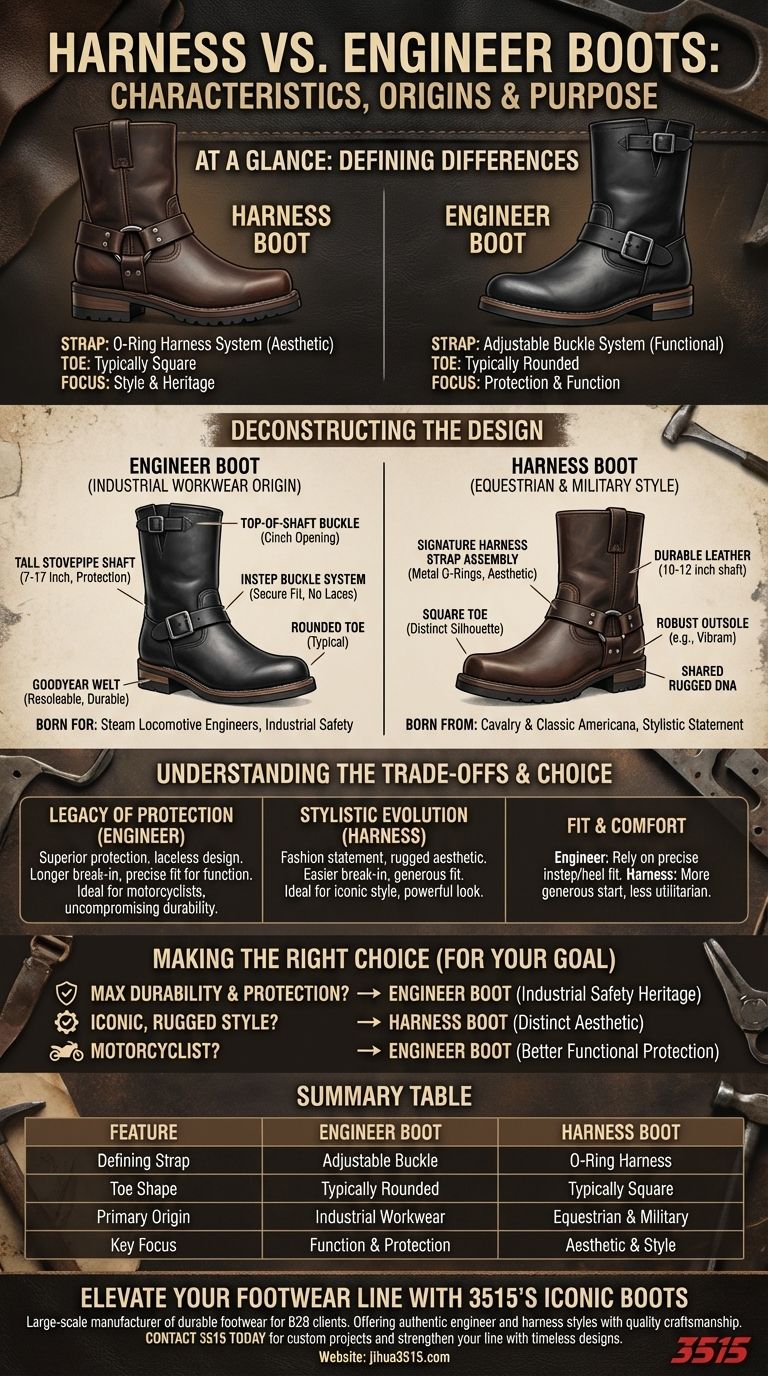

At a glance, harness and engineer boots are distinguished by their signature strap systems and common toe shapes. A harness boot is defined by a strap that wraps around the ankle, connected by metal O-rings on either side, and often features a square toe. In contrast, an engineer boot uses an adjustable buckle and strap across the instep and another at the top of the shaft, typically paired with a rounded toe.

While both boots share a rugged, laceless silhouette, their core difference lies in their origins. The engineer boot was born from pure function for industrial work, while the harness boot is a stylistic statement derived from equestrian and military gear.

Deconstructing the Engineer Boot

The engineer boot is a masterclass in purpose-built design. Every feature was developed to protect workers, specifically the steam locomotive engineers who needed durable footwear that wouldn't snag on machinery.

The Protective Shaft

An engineer boot’s most prominent feature is its tall, unstructured "stovepipe" shaft, which can range from 7 to 17 inches. This laceless design provided crucial protection against hot embers, steam, and abrasions in a tight engine cab.

The Instep Buckle System

Instead of laces, which could catch on controls or equipment, the engineer boot uses an adjustable leather strap and a metal buckle across the instep. This allows the wearer to secure the boot firmly to their foot.

The Top-of-Shaft Buckle

A second buckle and strap are located at the top of the shaft. This feature allows the wearer to cinch the boot's opening, preventing debris from falling inside.

The Foundational Construction

True to their workwear heritage, engineer boots are built for durability. They are typically made from thick, full-grain leather and constructed with a resoleable Goodyear welt or stitchdown method, ensuring a long service life.

Deconstructing the Harness Boot

The harness boot shares a similar rugged profile but draws its inspiration from a different lineage, blending elements of cavalry boots and classic Americana. Its defining characteristics are more stylistic than functional.

The Signature Harness Strap

The unmistakable feature is the harness strap assembly. This consists of leather straps that wrap around the front and back of the boot's ankle, connecting through two metal O-rings on each side. This element is purely aesthetic and defines the boot's identity.

The Common Toe Shape

While variations exist, the harness boot is most classically associated with a squared-off toe. This creates a distinct, bold silhouette that differs from the typically rounded toe of an engineer boot.

Shared Rugged DNA

Beyond their key differences, harness boots share many rugged qualities with engineer boots. They are typically 10-12 inches tall, crafted from durable leather, and often feature robust outsoles from brands like Vibram for excellent traction.

Understanding the Trade-offs

Choosing between these styles involves understanding their original intent, which directly impacts their modern feel and function.

Engineer Boot: A Legacy of Protection

The engineer boot's design is a direct result of its intended function. The tall shaft, lack of laces, and heavy-duty build offer superior protection, making it a favorite among motorcyclists and anyone needing uncompromising durability. The fit can take longer to break in but eventually molds perfectly to the foot.

Harness Boot: A Stylistic Evolution

The harness boot is primarily a fashion statement rooted in a rugged aesthetic. The harness itself serves no practical function for securing the boot. This style offers a powerful look without the same intense break-in period or utilitarian focus as a true engineer boot.

What This Means for Fit and Comfort

Because of its functional design, an engineer boot relies on a precise fit around the instep and heel to prevent slippage. A harness boot often has a more generous fit from the start, as its primary goal is not industrial performance.

Making the Right Choice for Your Goal

Your final decision should be guided by the role you want the boot to play in your wardrobe and life.

- If your primary focus is maximum durability and protection: The engineer boot is the superior choice, with a design heritage rooted in real-world industrial safety.

- If your primary focus is an iconic, rugged style: The harness boot delivers a distinct and powerful aesthetic statement that is immediately recognizable.

- If you are a motorcyclist: The engineer boot offers better functional protection with its tall shaft and secure, laceless design.

Ultimately, both boot styles offer a durable, timeless foundation built on a legacy of American craftsmanship.

Summary Table:

| Feature | Engineer Boot | Harness Boot |

|---|---|---|

| Defining Strap | Adjustable buckle across instep | Leather strap with metal O-rings |

| Toe Shape | Typically Rounded | Typically Square |

| Primary Origin | Industrial Workwear | Equestrian & Military Style |

| Key Focus | Function & Protection | Aesthetic & Style |

Elevate Your Footwear Line with 3515's Iconic Boots

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of rugged boots, including authentic engineer and harness styles built with the quality and craftsmanship your customers demand.

Contact 3515 today to discuss your custom boot project and strengthen your product line with timeless, American-inspired designs.

Visual Guide

Related Products

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- Why are industrial-grade Safety Boots essential for metal workshop floors? Protect Your Workforce Today

- What hazards do oilfield boots protect against? Essential PPE for Rig Safety

- What protective features are integrated into industrial work boots? 3 Key Safety Essentials for Construction Sites

- What are the main reasons for the popularity of moc toe boots? Unmatched Comfort, Durability & Style

- What are the consequences of wearing improper work shoes? Prevent Chronic Pain and Lost Productivity

- What jobs are moc toe boots good for? Essential Footwear for Trades on Hard Surfaces

- Why is manufacturer diversity and inclusion important in work boot design? For Superior Fit, Safety & Comfort

- What are the benefits of wedge soles in moc toe boots? Superior Comfort for Hard Surfaces