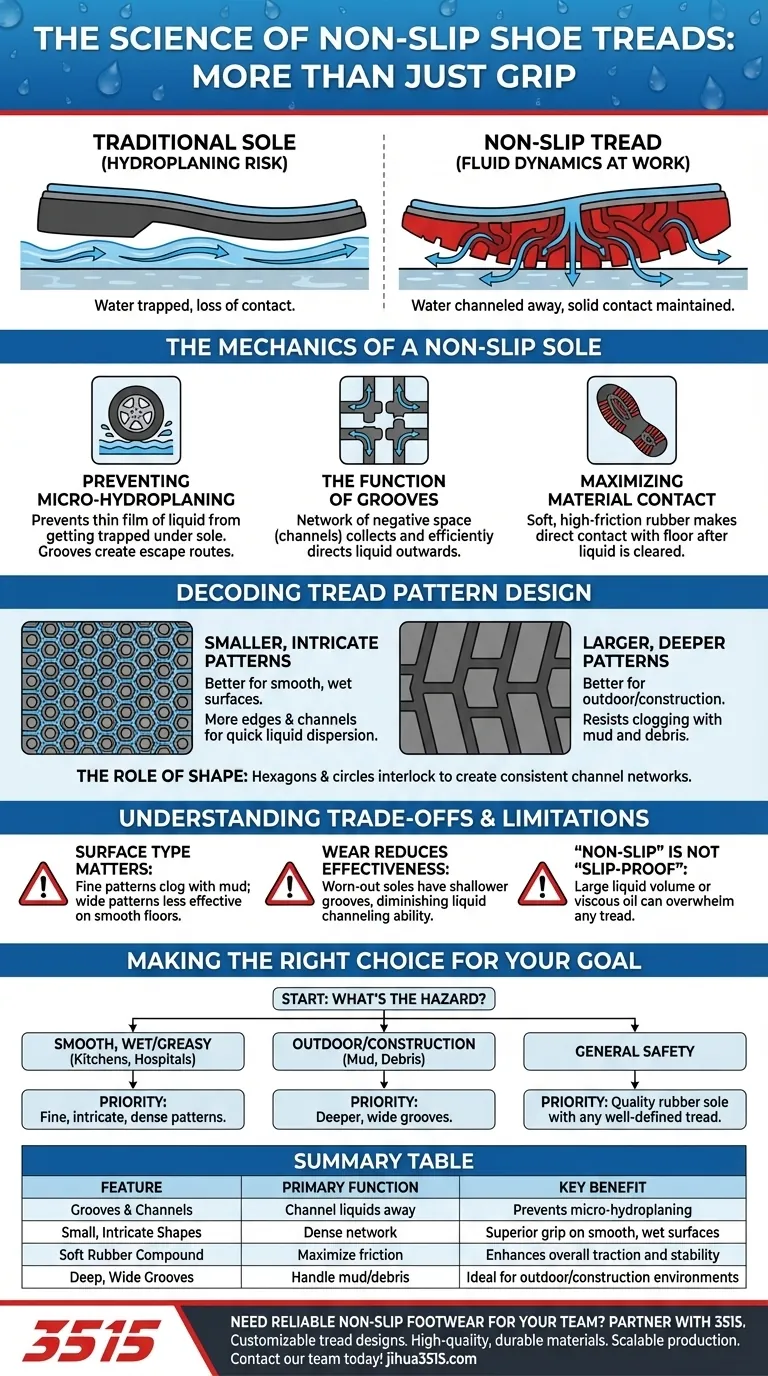

The tread pattern on a non-slip shoe serves a dual purpose. It is meticulously engineered to both create friction for grip and, more critically, to channel liquids like water and grease away from the point of contact. This prevents a thin layer of fluid from getting trapped under the sole, which is the primary cause of hydroplaning and dangerous slips on smooth surfaces.

While friction is important, the true function of a non-slip tread is fluid dynamics. Its intricate grooves act like the tread on a tire, pushing liquids out from under the shoe to maintain direct, solid contact between the sole and the floor.

The Mechanics of a Non-Slip Sole

To understand why tread patterns are so vital, we need to look beyond the simple idea of "grip" and into the physics of how we lose it.

Preventing Micro-Hydroplaning

The greatest risk on a wet floor isn't the water itself, but the shoe's inability to move it out of the way. When you step on a wet surface, your body weight can trap a thin film of liquid under the sole.

This trapped liquid can lift the sole off the floor, similar to how a car's tires can hydroplane on a wet road. The tread pattern's grooves create an escape route for this liquid, ensuring the sole material makes solid contact.

The Function of Grooves

The specific shapes—whether circles, hexagons, or squiggles—are less important than the network of channels, or grooves, they create.

These grooves are the negative space in the pattern. They are designed to collect liquid at the center of the foot and efficiently channel it outwards to the edges of the shoe.

Maximizing Material Contact

Non-slip shoes are typically made from soft rubber or synthetic rubber compounds that have a high coefficient of friction.

By clearing liquid away, the tread pattern ensures that as much of this high-friction material as possible is in direct contact with the floor, maximizing the shoe's gripping potential.

Decoding Tread Pattern Design

Not all tread patterns are created equal. The size, density, and design of the pattern directly impact its effectiveness in a given environment.

Why Smaller Patterns Are Better

The references consistently highlight that smaller, more intricate patterns generally provide superior slip resistance on smooth, wet floors.

A dense network of small shapes creates more edges to bite into the surface and, more importantly, provides more channels per square inch to disperse liquid quickly and efficiently.

The Role of Shape

Common shapes like hexagons and circles are effective because they interlock well, creating a consistent and complex network of grooves across the entire sole.

This ensures that no matter which part of the foot makes initial contact, there are immediate pathways to begin channeling fluid away.

Understanding the Trade-offs and Limitations

A non-slip shoe is a specialized tool, and its design involves compromises. Understanding these limitations is key to ensuring your safety.

Surface Type Matters

A tread pattern optimized for a kitchen floor with water or grease may not be ideal for a construction site.

Fine, dense patterns can become easily clogged with mud, gravel, or thick debris, rendering them ineffective. Environments with larger debris often require deeper, wider grooves that are less prone to clogging.

Wear and Tear Reduces Effectiveness

The effectiveness of a tread pattern is directly related to the depth of its grooves. As the sole wears down, these channels become shallower.

A worn-out sole, even if it feels "gummy," has a severely diminished ability to channel liquid. This is why a non-slip shoe must be replaced once the tread pattern is no longer distinct.

"Non-Slip" is Not "Slip-Proof"

Non-slip shoes significantly reduce the risk of falling, but they cannot eliminate it entirely. A large volume of liquid or a particularly viscous substance like heavy oil can overwhelm any tread design.

These shoes are a critical safety measure, but they must be paired with caution and awareness in hazardous environments.

Making the Right Choice for Your Goal

Selecting the correct shoe depends entirely on the specific hazards you face. Use the shoe's tread design as your primary guide.

- If your primary focus is working on smooth, wet, or greasy surfaces (kitchens, hospitals): Prioritize shoes with fine, intricate, and dense tread patterns to quickly disperse thin liquids.

- If your primary focus is navigating outdoor or construction environments: Look for deeper, wider grooves that can handle mud, dirt, and debris without clogging easily.

- If your primary focus is general safety in daily life: A quality rubber sole with any well-defined tread pattern will offer a significant safety improvement over standard footwear with flat soles.

Ultimately, understanding that a tread pattern's primary job is to manage liquid is the key to selecting footwear that truly keeps you safe and stable.

Summary Table:

| Tread Pattern Feature | Primary Function | Key Benefit |

|---|---|---|

| Grooves & Channels | Channel liquids away from sole | Prevents micro-hydroplaning |

| Small, Intricate Shapes | Create dense network for quick dispersion | Superior grip on smooth, wet surfaces |

| Soft Rubber Compound | Maximize friction with the floor | Enhances overall traction and stability |

| Deep, Wide Grooves | Handle mud and debris without clogging | Ideal for outdoor/construction environments |

Need Reliable Non-Slip Footwear for Your Team? Partner with 3515.

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our expertise in engineering effective tread patterns ensures your workforce is protected against slips and falls in any environment—from kitchens and hospitals to construction sites.

We offer:

- Customizable tread designs tailored to your specific hazards.

- High-quality, durable rubber compounds for maximum grip and longevity.

- Scalable production to meet any order volume with consistent quality.

Enhance workplace safety with footwear built on proven physics. Contact our team today to discuss your needs and request a quote!

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

People Also Ask

- What is the general perception of non-slip shoes in workplace safety? Uncover the Truth About Slip-Resistant Footwear

- What are the six common types of non-slip shoes? Find the Perfect Grip for Your Work Environment

- Why should someone wear slip resistant shoes? Prevent Costly Workplace Injuries

- What are the benefits of specialized shoes for doctors? Enhance Comfort, Safety, and Endurance

- What combination of features prevents non-slip shoes from slipping? The Science of Sole Material, Tread, and Liquid Displacement

- Why are pressure insole systems necessary for analyzing gait phases during curved walking slip studies? | 3515 Insights

- What are the essential features for restaurant and food service work shoes? Ensure Safety and Comfort for Your Team

- What design features are typically found in slip-resistant shoes? Essential Elements for Workplace Safety