The defining characteristics of a slip-resistant shoe are almost entirely in its outsole. These shoes are engineered with specific materials and tread patterns designed to maximize grip and channel liquids away from the sole's surface. Key features include soft rubber or synthetic compounds, deep grooves, and intricate, multi-directional patterns like hexagons or circles that create more contact points with the floor.

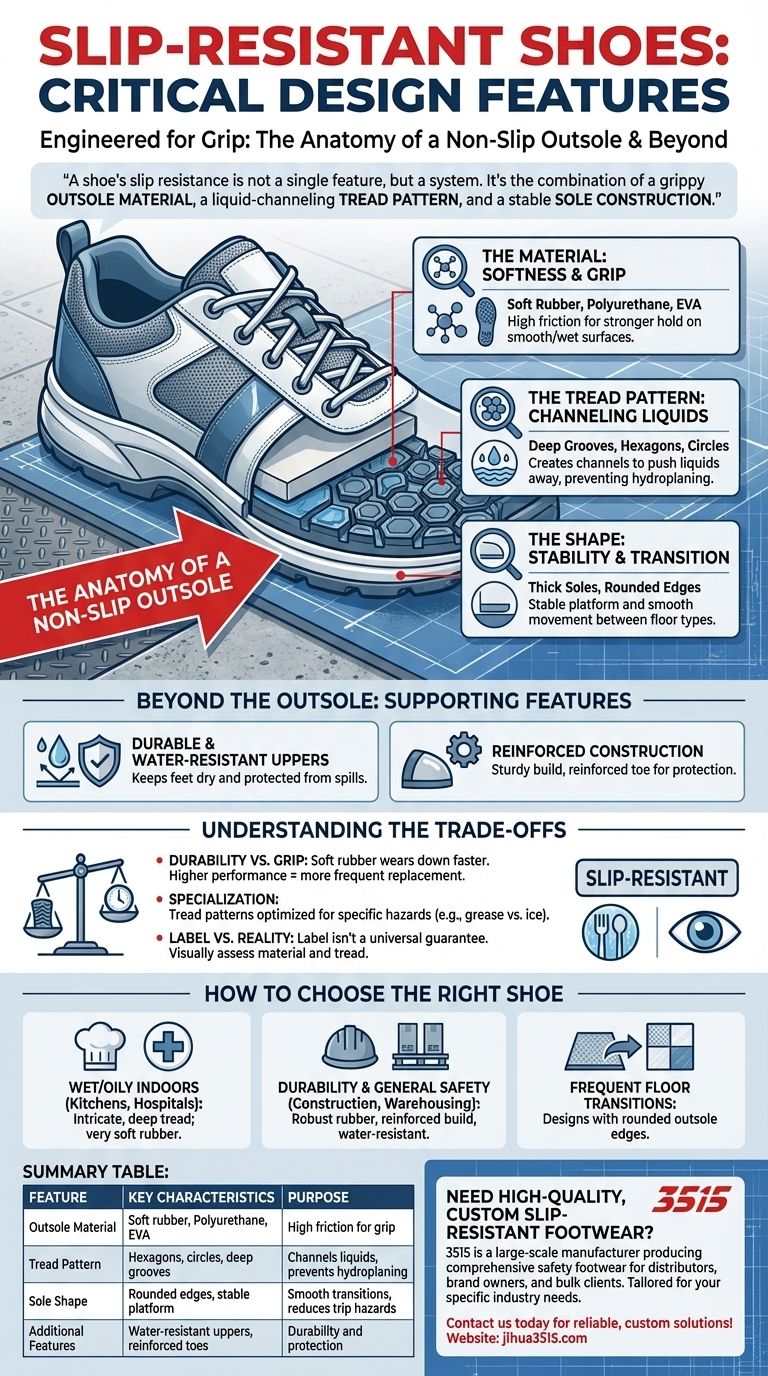

A shoe's slip resistance is not a single feature, but a system. It's the combination of a grippy outsole material, a liquid-channeling tread pattern, and a stable sole construction that provides reliable traction on hazardous surfaces.

The Anatomy of a Non-Slip Outsole

The vast majority of a shoe's ability to prevent slips comes from the design of its outsole—the part that directly contacts the ground. Three elements work together to achieve this.

The Material: Softness and Grip

The foundation of a non-slip shoe is the material used for the sole. Manufacturers typically use high-grade, soft rubber or specialized synthetics like polyurethane or EVA (ethylene vinyl acetate).

These materials are chosen for their high coefficient of friction, which allows them to create a stronger hold on smooth or wet surfaces compared to the harder plastics found on standard footwear.

The Tread Pattern: Channeling Liquids

The pattern of the tread is arguably the most critical design feature. Unlike a flat sole, which can hydroplane on a thin layer of liquid, a non-slip tread is designed to actively manage fluids.

It features deep grooves and intricate, enclosed shapes like hexagons, circles, or squiggles. This design creates numerous small channels that push water, oil, and other liquids away from the sole, allowing the rubber to make direct contact with the floor.

The Shape: Stability and Transition

The overall shape and thickness of the sole also contribute to safety. Slip-resistant shoes often have thick, durable soles that provide a stable platform and support for the foot during long periods of standing.

Some designs also feature slightly rounded edges and "reduced trip-hazard zones." These subtle features help ensure smooth movement when transitioning between different types of flooring, such as from a carpeted area to a slick tile floor.

Beyond the Outsole: Supporting Features

While the outsole does the heavy lifting, other aspects of the shoe's design enhance its overall safety and utility in demanding environments.

Durable and Water-Resistant Uppers

In many workplaces where slip-resistance is necessary, spills are common. For this reason, many non-slip shoes are built with water-resistant upper materials. This feature keeps the wearer's feet dry and protected from hot or hazardous liquids.

Reinforced Construction

Because these shoes are intended for professional use, they are often built with sturdy construction and reinforced materials. Some models may include features like a reinforced toe to protect against falling objects, making them suitable for unpredictable conditions.

Understanding the Trade-offs

No single shoe is perfect for every situation. Understanding the inherent compromises in slip-resistant designs is key to making an informed choice.

Durability vs. Grip

The soft rubber compounds that provide excellent grip tend to wear down faster than the harder soles found on typical shoes. This means that a high-performance, non-slip shoe may need to be replaced more frequently to maintain its effectiveness.

Specialization for Surfaces

A shoe designed to excel on a greasy kitchen floor may not offer the same level of performance on an icy sidewalk. The tread patterns are often optimized for specific types of hazards, primarily liquids on flat surfaces.

The Label vs. Reality

While an explicit "slip-resistant" label indicates the shoe has passed certain performance tests, it's not a guarantee of universal safety. Understanding the physical features—the material and tread pattern—allows you to visually assess a shoe's potential effectiveness for your specific environment.

How to Choose the Right Shoe

Your specific environment and tasks dictate which design features are most critical for your safety.

- If your primary focus is wet or oily indoor surfaces (e.g., kitchens, hospitals): Prioritize shoes with intricate, deep tread patterns made from very soft rubber.

- If your primary focus is durability and general safety (e.g., construction, warehousing): Look for a combination of a robust rubber sole, reinforced construction, and water-resistant uppers.

- If your primary focus is frequent movement between different floor types: Seek out designs with rounded outsole edges to minimize the risk of catching an edge and stumbling.

By looking beyond the label and understanding these core design principles, you can confidently select footwear that provides genuine stability and safety.

Summary Table:

| Feature | Key Characteristics | Purpose |

|---|---|---|

| Outsole Material | Soft rubber, polyurethane, or EVA | High friction for grip on wet/smooth surfaces |

| Tread Pattern | Hexagons, circles, deep grooves | Channels liquids away, prevents hydroplaning |

| Sole Shape | Rounded edges, stable platform | Smooth transitions, reduces trip hazards |

| Additional Features | Water-resistant uppers, reinforced toes | Durability and protection in demanding environments |

Need high-quality, custom slip-resistant footwear for your business?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of slip-resistant shoes and boots, tailored to your specific industry needs—whether for kitchens, hospitals, construction, or warehousing.

We combine advanced materials, precise tread engineering, and durable construction to deliver footwear that meets the highest safety standards.

Contact us today to discuss your requirements and get a quote for reliable, custom safety footwear solutions!

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

People Also Ask

- What do the markings on ASTM-compliant safety shoes indicate? Decode the Safety Labels for Maximum Protection

- What are the conditions faced by employees in meatpacking and poultry slaughter plants? Navigating Pervasive Slip Hazards

- What are the EN ISO 20345 norms for safety shoes? A Guide to Choosing the Right Protection

- Why is expert help recommended when selecting safety shoes? Ensure Perfect Fit & Hazard Protection

- Why is slip resistance important in safety footwear? Prevent Costly Workplace Slips and Falls