The most common types of non-slip footwear are generally categorized as work shoes, chef clogs, athletic sneakers, server shoes, safety boots, and outdoor sandals. While these styles look different, their non-slip capability isn't defined by their appearance but by the specific materials and tread patterns of their outsoles, each engineered for a distinct environment.

The term "non-slip" is not about the style of the shoe but the technology of its sole. True effectiveness comes from matching the outsole's specific rubber compound and tread design to the surface you will encounter, whether it's a greasy kitchen floor or a wet, rocky trail.

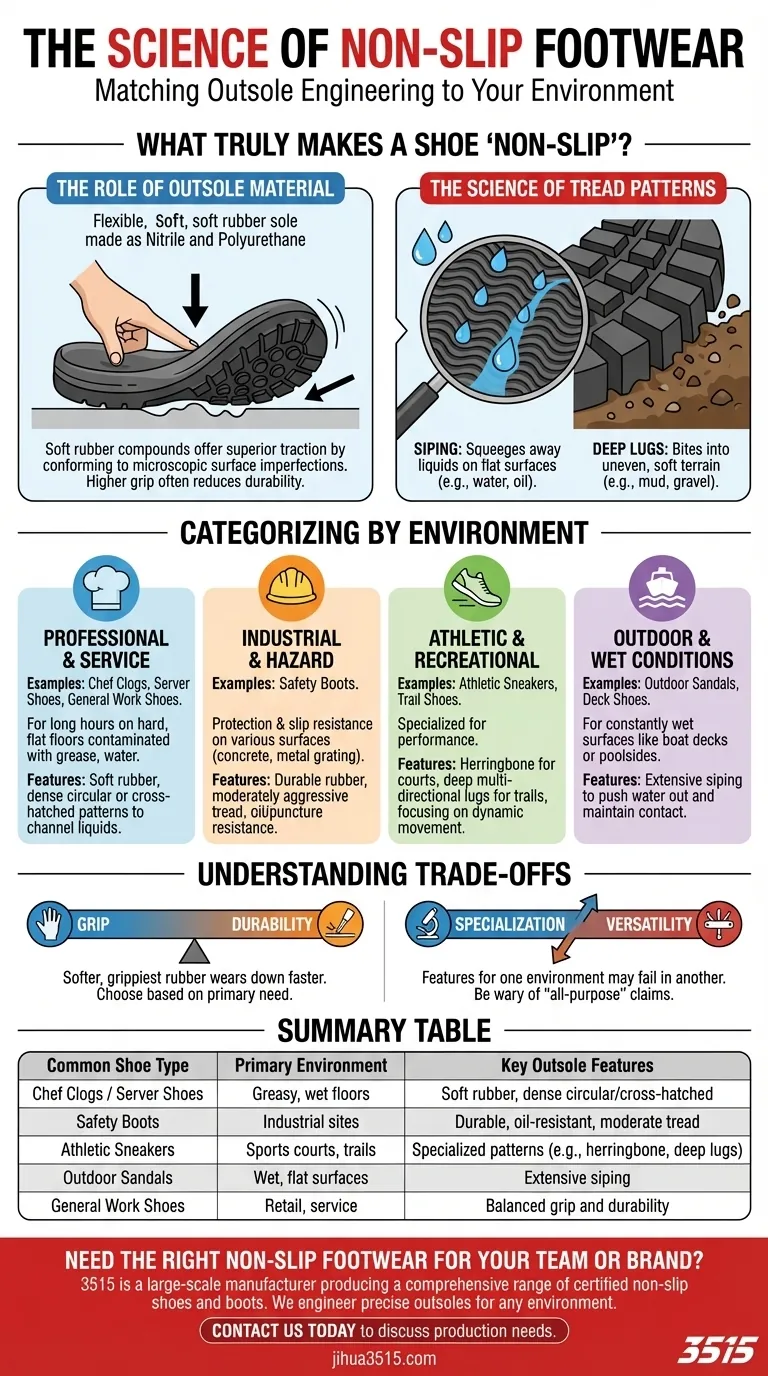

What Truly Makes a Shoe "Non-Slip"?

Understanding a shoe's slip resistance requires looking past its general category and focusing on the two core components of its outsole: the material and the pattern.

The Role of Outsole Material

The compound used to create the outsole is the foundation of its grip. Softer rubber compounds, such as nitrile and polyurethane, offer superior traction because they can conform better to microscopic imperfections on a surface. However, this increased grip often comes at the cost of durability.

The Science of Tread Patterns

The design of the tread channels away substances that interfere with contact between the shoe and the floor. The pattern is highly specialized for the intended surface.

Small, intricate patterns with many fine edges (called siping) are designed to squeegee liquids like water and oil away on flat surfaces. Conversely, deep, wide-spaced lugs are built to bite into soft, uneven terrain like mud and gravel.

Categorizing Non-Slip Shoes by Environment

Instead of thinking in terms of shoe style, it's more effective to categorize them by the environment they are built to handle.

Professional & Service Environments

This category includes chef clogs, server shoes, and general work shoes used in hospitals or retail. They are designed for long hours of standing on hard, flat surfaces that are frequently contaminated with water, grease, or cleaning fluids. Their outsoles typically feature soft rubber and dense, circular, or cross-hatched tread patterns to maximize surface contact and channel liquids away.

Industrial & Hazard Environments

Safety boots fall into this class. Their primary function is protection, but certified slip resistance is a critical safety feature. The outsoles must provide grip on various surfaces, from smooth concrete to metal grating, while also resisting punctures, oil, and chemicals. These often have a durable rubber compound and a moderately aggressive tread pattern.

Athletic & Recreational Use

Athletic sneakers are a broad category where slip resistance is specialized for performance. A basketball shoe has a herringbone pattern for grip on a polished hardwood court. A trail running shoe has deep, multi-directional lugs for traction on dirt, rocks, and roots. The priority is grip during dynamic, high-impact movement.

Outdoor & Wet Conditions

This group includes outdoor sandals and deck shoes. These are engineered for surfaces that are constantly wet, like a boat deck, poolside, or riverbank. Their key feature is heavy siping—thin slits in the rubber that act like a car tire's tread on a wet road, efficiently pushing water out from under the shoe to maintain contact with the surface.

Understanding the Trade-offs

No single non-slip shoe is perfect for all conditions. Choosing the right one means understanding the inherent compromises in its design.

Grip vs. Durability

The softest, grippiest rubber compounds wear down the fastest. A shoe designed for maximum grip in a kitchen will not last long if used daily on abrasive asphalt. You must choose based on your primary need.

Specialization vs. Versatility

The features that make a shoe excel in one environment make it ineffective in another. A chef's clog with a micro-siped sole offers no traction in mud, and a hiking boot with deep lugs can feel unstable and clumsy on a flat, wet floor.

The Myth of "All-Purpose"

Be wary of any shoe marketed as a universal non-slip solution. The engineering required to resist oil on a smooth floor is fundamentally different from what's needed to grip loose gravel on a trail.

How to Choose the Right Non-Slip Shoe

Evaluate your primary environment and select footwear designed specifically for those challenges.

- If your primary focus is a service industry job (kitchen, hospital): Look for shoes with soft rubber outsoles and dense, intricate tread patterns certified for oily and wet conditions.

- If your primary focus is construction or industrial work: Prioritize safety boots that combine a certified slip-resistant sole with protective features like a steel toe and puncture plate.

- If your primary focus is outdoor activities like hiking: You need shoes with deep, widely-spaced lugs made from a durable rubber compound for grip on uneven terrain.

- If your primary focus is recreation on wet, flat surfaces (boating, fishing): Choose footwear with extensive siping in the outsole to effectively channel water away.

Choosing the right footwear is about matching the engineering of the outsole to the specific challenges of your environment.

Summary Table:

| Common Non-Slip Shoe Type | Primary Environment | Key Outsole Features |

|---|---|---|

| Chef Clogs / Server Shoes | Greasy, wet floors (kitchens, hospitals) | Soft rubber, dense circular/cross-hatched tread |

| Safety Boots | Industrial sites (concrete, metal) | Durable, oil-resistant rubber, moderate tread |

| Athletic Sneakers | Sports courts, trails | Specialized patterns (e.g., herringbone for courts, deep lugs for trails) |

| Outdoor Sandals | Wet, flat surfaces (decks, poolsides) | Extensive siping to channel water |

| General Work Shoes | Retail, service industries | Balanced grip and durability for hard floors |

Need the right non-slip footwear for your team or brand?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified non-slip shoes and boots for distributors, brand owners, and bulk clients. We can engineer outsoles with the precise rubber compounds and tread patterns required for your specific environment—whether it's a greasy kitchen, a construction site, or an outdoor trail.

Contact us today to discuss your production needs and get a quote. Let us help you provide safer, more effective footwear.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

People Also Ask

- Why does the material performance of professional slip-resistant shoes offer superior safety? Hardware vs. Behavior

- Why are metal surfaces often selected as the walking medium in studies concerning ramp safety? Achieve Lab-Grade Precision

- What is the purpose of requiring subjects to wear anti-slip socks and tight-fitting sportswear? Optimize Sensor Data

- How does the shock-absorption technology in safety footwear help reduce injury? Protect Your Skeletal Health Today

- What is the primary objective of utilizing dedicated safety shoes in nanomaterial work zones? Prevent Track-Out Now