It is the specific combination of sole material, tread pattern, and liquid displacement that prevents a non-slip shoe from slipping. A soft but sturdy rubber sole provides the initial friction, while an intricate tread pattern actively channels liquids like water and oil out from underneath the shoe. This allows the sole to make direct, solid contact with the ground, creating a secure grip where a normal shoe would hydroplane.

The true function of a non-slip shoe is not just to grip the floor, but to manage the thin layer of liquid that causes the slip in the first place. The tread pattern acts as a system of channels to clear this layer, allowing the high-friction sole material to do its job effectively.

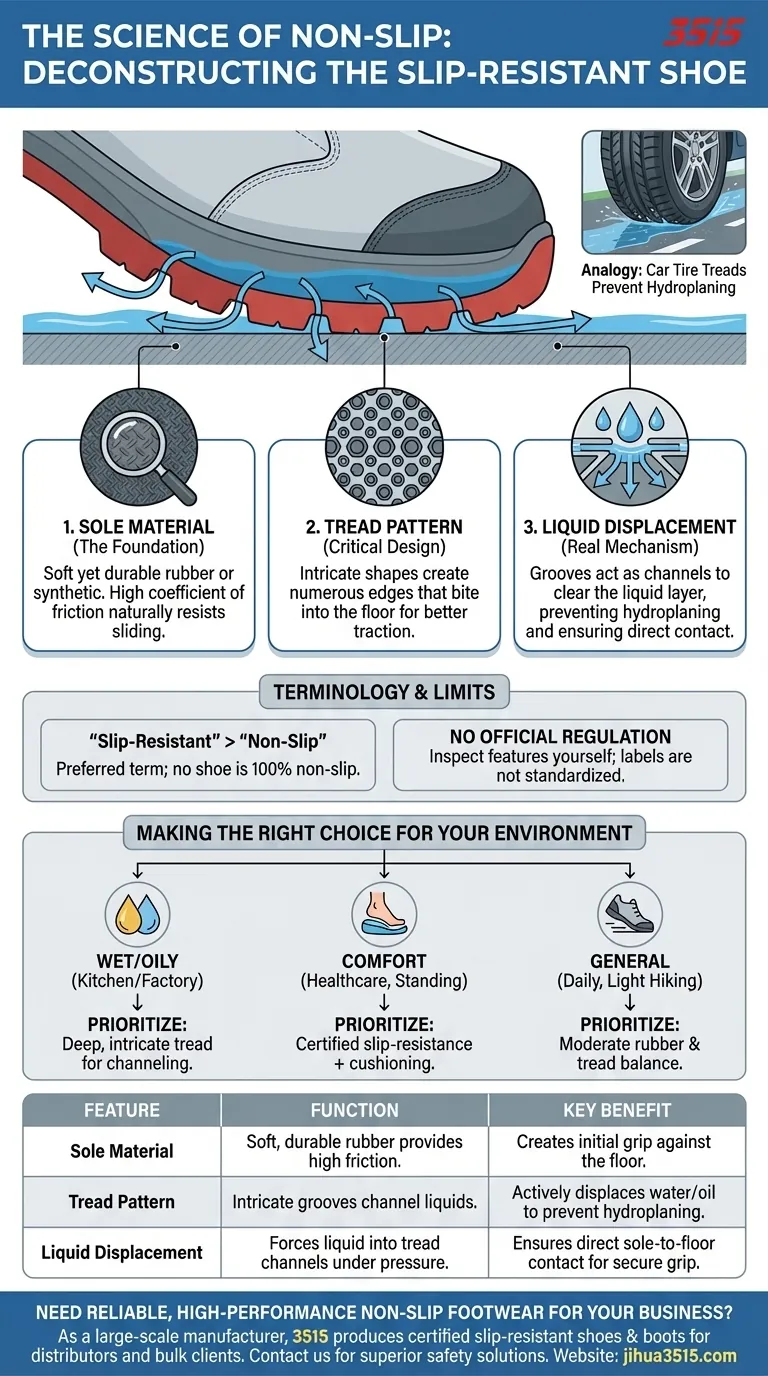

The Science of Grip: Deconstructing the Non-Slip Shoe

To understand why these shoes work, you must look at how each component solves a specific part of the slipping problem.

The Foundation: Sole Material

The sole is almost always made from a soft yet durable rubber or synthetic rubber. This material is chosen for its high coefficient of friction, which naturally resists sliding against a surface. A harder material like plastic or leather would slide much more easily.

The Critical Design: Tread Pattern

The pattern cut into the bottom of the sole is the most important design feature. These patterns, often small hexagons or circles, are not random. Their small, intricate shapes create numerous small edges that can bite into the floor surface for better traction.

The Real Mechanism: Liquid Displacement

This is the key to preventing slips on wet or oily surfaces. The grooves in the tread pattern create a network of channels. When you step on a wet spot, the pressure of your weight forces the liquid out from under the shoe and into these channels.

This displacement ensures the rubber sole makes direct contact with the floor, preventing a layer of liquid from causing you to hydroplane, much like the treads on a car tire prevent skidding on a wet road.

Understanding the Terminology and Its Limits

Navigating the market for these shoes requires understanding the language used and its limitations.

"Non-Slip" vs. "Slip-Resistant"

These two terms are used interchangeably by manufacturers and experts. However, scientific and consumer protection organizations prefer the term "slip-resistant" because no shoe can be 100% non-slip in all conditions.

The Lack of Regulation

Crucially, there is no official, regulated definition for either term. A manufacturer can label a shoe "non-slip" without meeting a specific standard. This means you cannot rely on the label alone and must inspect the shoe's features yourself.

Making the Right Choice for Your Environment

Your specific needs will determine which features to prioritize.

- If your primary focus is safety in a wet or oily environment (e.g., a kitchen or factory): Prioritize shoes with deep, intricate tread patterns specifically designed to channel liquids away.

- If your primary focus is comfort during long hours of standing (e.g., healthcare): Look for a combination of certified slip-resistant soles and thick, supportive cushioning to reduce fatigue.

- If your primary focus is general-purpose traction (e.g., daily wear or light hiking): A quality rubber sole with a moderate tread will provide a good balance of grip and flexibility for various surfaces.

By understanding how these features work together, you can look past the marketing and choose a shoe that genuinely delivers the safety you need.

Summary Table:

| Feature | Function | Key Benefit |

|---|---|---|

| Sole Material | Soft, durable rubber provides high friction. | Creates initial grip against the floor surface. |

| Tread Pattern | Intricate grooves (hexagons, circles) channel liquids. | Actively displaces water and oil to prevent hydroplaning. |

| Liquid Displacement | Forces liquid into tread channels under pressure. | Ensures direct sole-to-floor contact for a secure grip. |

Need reliable, high-performance non-slip footwear for your business?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified slip-resistant shoes and boots for distributors, brand owners, and bulk clients. Our expertise in combining advanced sole compounds with scientifically designed tread patterns ensures superior safety and durability for demanding environments like kitchens, factories, and healthcare facilities.

Contact us today to discuss your specific needs and discover how we can enhance your product line with footwear that genuinely works.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Customizable Slip-On Safety Shoes Direct from the Factory for Wholesale

People Also Ask

- How do high friction coefficient anti-slip outsoles contribute to workplace safety? Maximize Industrial Traction

- What are the key benefits of men's work shoes in terms of durability? Maximize Safety & Longevity

- How do lightweight construction and easy-entry designs in footwear contribute to fall prevention? Enhance Safety Now

- How can you test the arch support of slip-resistant shoes? The Simple Bend Test for All-Day Comfort

- What is the technical function of five-star GRIP rated footwear? Maximize Safety with Advanced Traction Engineering

- What are the differences between non-slip shoes and regular shoes? Enhance Workplace Safety & Stability

- What are the key design considerations for high-friction anti-slip outsoles? Master Safety with Advanced Tread Science

- What is the benefit of angled or rounded sole designs in non-slip shoes? Prevent Hydroplaning for Superior Grip