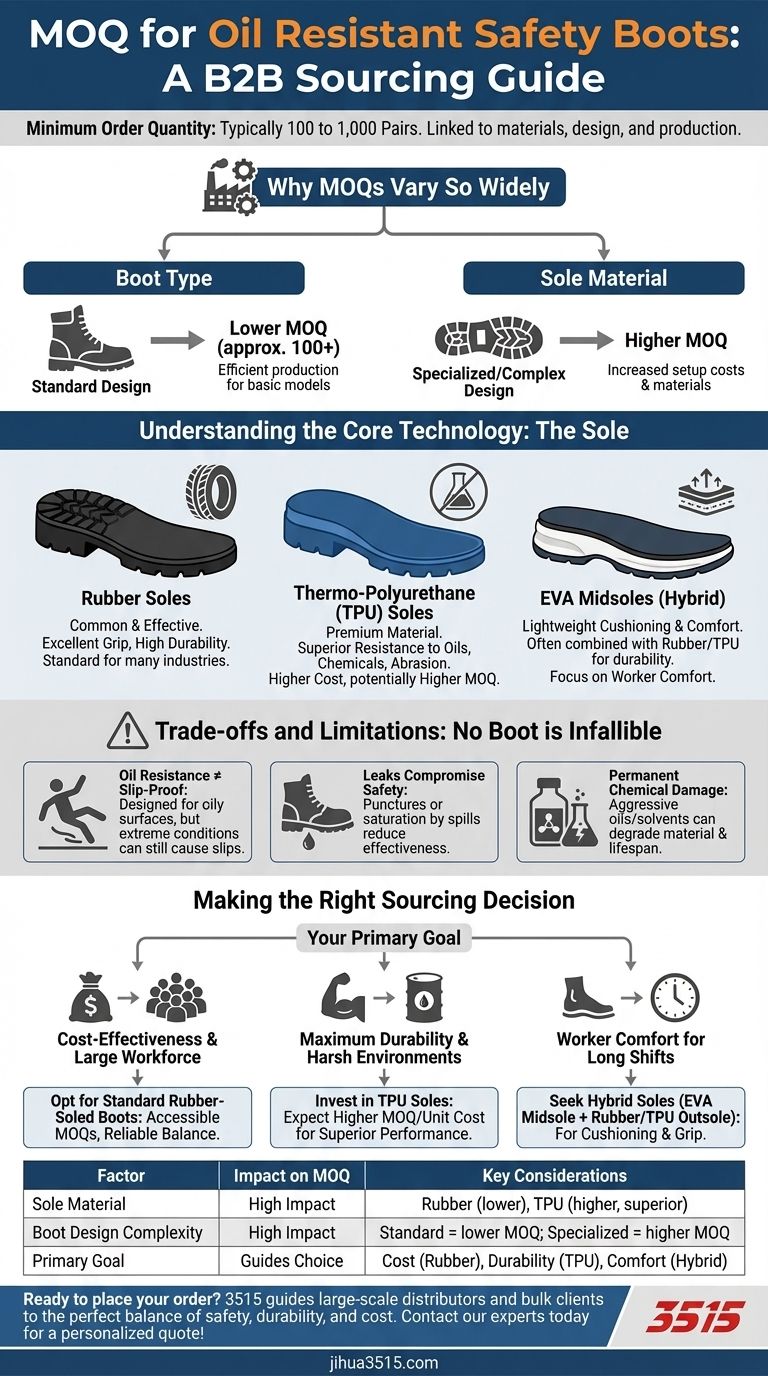

To be clear, the minimum order quantity (MOQ) for oil-resistant safety boots typically ranges between 100 to 1,000 pairs. This significant variation is not arbitrary; it is directly tied to the specific materials, design complexity, and manufacturing processes required for the boot you choose.

While the MOQ is a key logistical figure, the more critical factor for any buyer is understanding how the choice of sole material impacts not only the order quantity but also the boot's long-term performance, durability, and true safety value.

Why MOQs Vary So Widely

The minimum order is set by the manufacturer to cover the costs of a production run. A simple, standard-design boot will naturally have a lower barrier to entry than one requiring specialized materials or complex assembly.

The Role of Boot Type

A basic, widely produced boot model using common materials will often have a lower MOQ, closer to the 100-pair mark. Manufacturers can produce these more efficiently.

The Impact of Sole Material

The specific material used for the sole is a primary driver of cost and manufacturing setup. Sourcing specialized polymers or setting up molds for less common designs increases the upfront cost, which in turn raises the MOQ.

Understanding the Core Technology: The Sole

The effectiveness of an oil-resistant safety boot is almost entirely dependent on the composition and design of its sole. Different materials offer a distinct balance of safety, durability, and comfort.

Rubber Soles

Rubber is a common and effective choice for oil resistance. It provides excellent grip and is highly durable, making it a standard for many industrial environments.

Thermo-Polyurethane (TPU) Soles

TPU is a premium material known for its superior resistance to oils, chemicals, and abrasion. Boots with TPU soles are exceptionally durable, often justifying a higher cost and potentially a higher MOQ.

Ethylene-Vinyl Acetate (EVA) Midsoles

EVA is a lightweight, foam-like material prized for its cushioning and comfort. It is typically used as a midsole for shock absorption, combined with a more durable rubber or TPU outsole that makes contact with the ground.

Understanding the Trade-offs and Limitations

No safety boot is infallible. Acknowledging the inherent limitations of the technology is crucial for making an informed purchasing decision and setting correct safety expectations for your team.

Oil Resistance Does Not Equal Slip-Proof

While these boots are designed to resist degradation from oil and provide grip on oily surfaces, they can still slip in extremely slick conditions. The "non-slip" feature has its limits.

Leaks Compromise Safety

The oil-resistant properties are only effective if the boot is fully intact. Any leak, puncture, or significant spill that saturates the boot's upper material can reduce its effectiveness and compromise safety.

Chemical Damage Can Be Permanent

Certain aggressive oils or chemical solvents can permanently damage the sole's material. This can degrade the non-slip surface and reduce the boot's overall lifespan and protective capabilities.

Making the Right Sourcing Decision

Your choice should be guided by your specific workplace environment and priorities. Align your boot specifications with your primary goal to navigate MOQ requirements effectively.

- If your primary focus is cost-effectiveness for a large workforce: Opt for standard-design rubber-soled boots, which typically offer the most accessible MOQs and a reliable balance of safety and durability.

- If your primary focus is maximum durability in harsh chemical environments: Invest in boots with TPU soles, and be prepared for a potentially higher MOQ and unit cost that reflects their superior performance.

- If your primary focus is worker comfort for long shifts: Seek out boots with a hybrid sole construction, such as an EVA midsole for cushioning and a rubber or TPU outsole for grip and resistance.

Ultimately, choosing the right safety boot is an investment in your team's safety and operational productivity.

Summary Table:

| Factor | Impact on MOQ | Key Considerations |

|---|---|---|

| Sole Material | High Impact | Rubber (lower MOQ), TPU (higher MOQ, superior durability). |

| Boot Design Complexity | High Impact | Standard designs have lower MOQs than specialized/custom models. |

| Primary Goal | Guides Choice | Cost-effectiveness (rubber), maximum durability (TPU), comfort (EVA/rubber hybrid). |

Ready to place your order for high-quality oil-resistant safety boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of industrial footwear for distributors, brand owners, and bulk clients. We guide you through MOQ options to find the perfect balance of safety, durability, and cost for your workforce.

Contact our experts today for a personalized quote and discover how our production capabilities can meet your specific requirements.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- How do ergonomic designs and industrial safety features in footwear improve health? Maximize Safety & Compliance

- Why is professional-grade safety footwear essential for workers with peripheral neuropathy? Expert Protection Guide

- What role do industrial-grade safety shoes play in risk management within the concrete industry Occupational Health and Safety Management System (SMK3)? Elevate Safety & Compliance

- What features should be considered when selecting oil resistant safety boots? Ensure Maximum Protection & Comfort

- Why are industrial CAD/CAM systems essential for safety shoe production? Transform Your Footwear Manufacturing Today

- What primary protective functions do industrial safety shoes provide for personnel working on an airport apron?

- What are the main hazards that safety footwear is designed to protect against? A Guide to Essential Foot Protection

- What is the role of high-definition USB cameras in the detection of safety shoes? Enhancing Site Safety with HD Clarity