At its core, safety footwear is engineered to prevent serious workplace foot injuries. It is designed to provide a critical barrier against a wide range of hazards, including direct physical threats like impacts from falling objects, compression, punctures from sharp items, and electrical shocks, as well as environmental risks like slippery surfaces, extreme temperatures, and chemical exposure.

While safety footwear is fundamentally about protecting feet from direct physical hazards, its true value lies in creating a foundation for overall worker safety. The right footwear mitigates specific risks while also improving stability and reducing fatigue, preventing a much wider range of potential accidents.

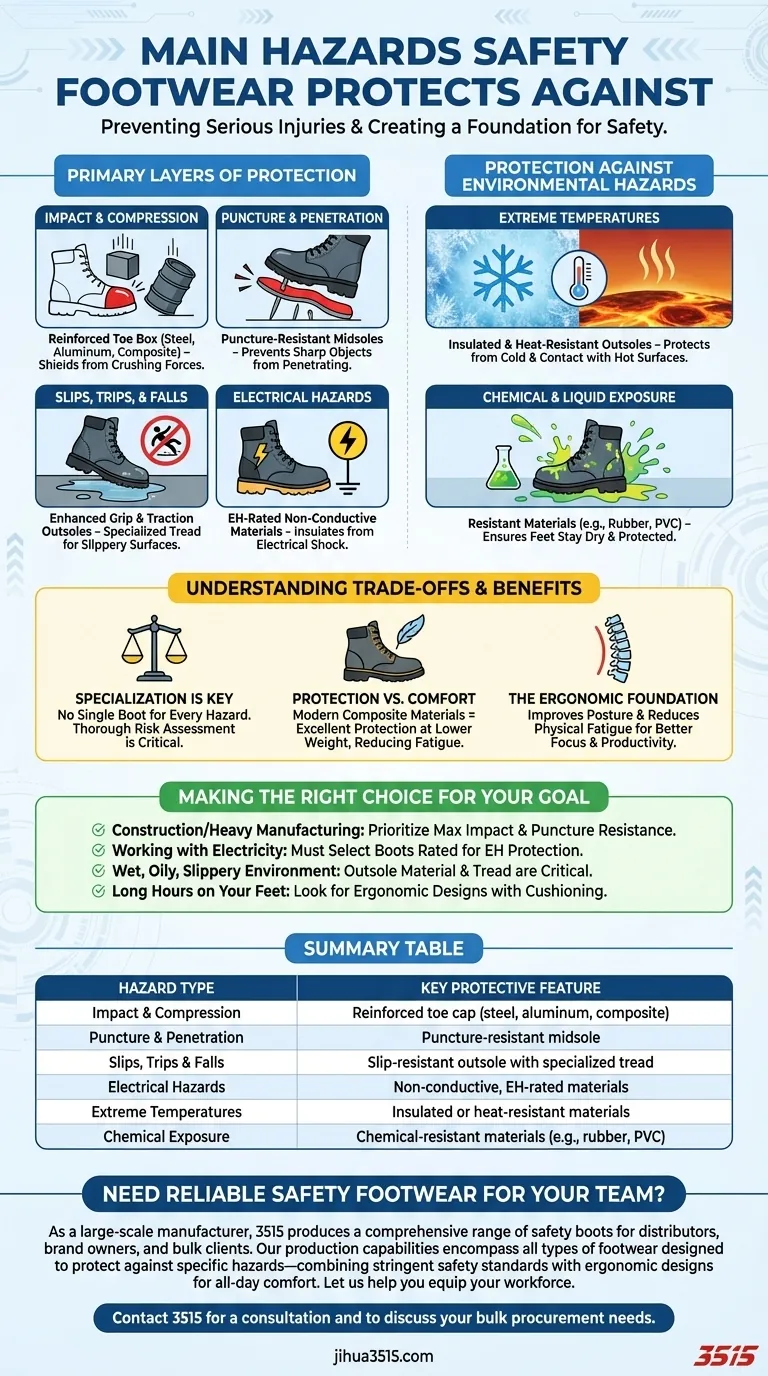

The Primary Layers of Protection

Understanding the specific threats safety footwear is designed to counter is the first step in selecting the appropriate protection for any given task or environment.

Impact and Compression

This is the most recognized function of safety footwear. A reinforced toe box, typically made of steel, aluminum, or composite materials, protects the foot from the crushing force of falling or rolling objects.

Puncture and Penetration

Sharp objects on the ground, such as nails, screws, or metal shards, pose a significant risk. Safety footwear with puncture-resistant midsoles prevents these items from penetrating the bottom of the boot and injuring the sole of the foot.

Slips, Trips, and Falls

Slips are one of the most common causes of workplace accidents. The outsole of safety footwear is designed with specific materials and tread patterns to provide enhanced grip and traction on wet, oily, or otherwise slippery surfaces.

Electrical Hazards

For those working near live electrical circuits, specialized footwear is essential. Electrical Hazard (EH) rated boots are made from non-conductive materials that insulate the wearer from the ground, significantly reducing the risk of electric shock.

Protection Against Environmental Hazards

Beyond direct mechanical or electrical threats, safety footwear must also shield the wearer from the specific conditions of their work environment.

Extreme Temperatures

Working in very hot or cold conditions can lead to serious foot injuries. Insulated footwear protects against the cold, while boots made with heat-resistant outsoles protect against contact with hot surfaces, such as in paving or welding.

Chemical and Liquid Exposure

Exposure to corrosive chemicals, solvents, or even excessive water can degrade footwear and harm the skin. Safety boots made from resistant materials ensure feet stay dry and are protected from chemical splashes or submersion.

Understanding the Trade-offs and Benefits

Selecting the right footwear involves more than just matching a boot to a single hazard. It's about finding the right balance for the specific job and recognizing the broader impact of proper footwear.

Specialization is Key

A boot with a maximum-traction outsole for slippery floors may not have the best insulation for cold environments. No single boot is perfect for every hazard. A thorough risk assessment of the workplace is critical to identify the most important protective features needed.

Protection vs. Comfort

Historically, greater protection meant heavier, more cumbersome boots. However, modern composite materials offer excellent protection at a lower weight, reducing fatigue over long shifts. Investing in a boot that is both safe and comfortable is not a luxury; it's a prerequisite for sustained focus and productivity.

The Ergonomic Foundation

Properly designed safety footwear does more than just shield the foot from external harm. It provides essential arch and ankle support, which improves posture and reduces physical fatigue in the feet, legs, and lower back. By minimizing discomfort, workers are better able to concentrate, leading to fewer errors and a safer work environment for everyone.

Making the Right Choice for Your Goal

Your specific work environment dictates the type of protection you need most.

- If your primary focus is construction or heavy manufacturing: Prioritize footwear with maximum impact, compression, and puncture resistance from steel or composite toes and midsoles.

- If your primary focus is working with electricity: You must select boots specifically rated for Electrical Hazard (EH) protection to ensure proper insulation.

- If your primary focus is a wet, oily, or slippery environment: The outsole's material and tread design are the most critical factors for preventing falls.

- If your primary focus is long hours spent on your feet: Look for ergonomic designs that offer excellent cushioning and support to minimize fatigue and improve overall well-being.

Choosing the correct safety footwear is a foundational investment in both individual health and operational success.

Summary Table:

| Hazard Type | Key Protective Feature |

|---|---|

| Impact & Compression | Reinforced toe cap (steel, aluminum, composite) |

| Puncture & Penetration | Puncture-resistant midsole |

| Slips, Trips & Falls | Slip-resistant outsole with specialized tread |

| Electrical Hazards | Non-conductive, EH-rated materials |

| Extreme Temperatures | Insulated or heat-resistant materials |

| Chemical Exposure | Chemical-resistant materials (e.g., rubber, PVC) |

Need reliable safety footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of footwear designed to protect against the specific hazards in your industry—from impact and puncture resistance to electrical hazard protection and superior slip resistance.

We combine stringent safety standards with ergonomic designs for all-day comfort, helping to reduce fatigue and improve productivity. Let us help you equip your workforce with the right protection.

Contact 3515 today for a consultation and to discuss your bulk procurement needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

People Also Ask

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What materials are used for safety toes? Choose Steel, Composite, or Aluminum for Your Work Boots

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What are the primary protective functions of composite-toe boots? A Guide to Modern Safety Footwear