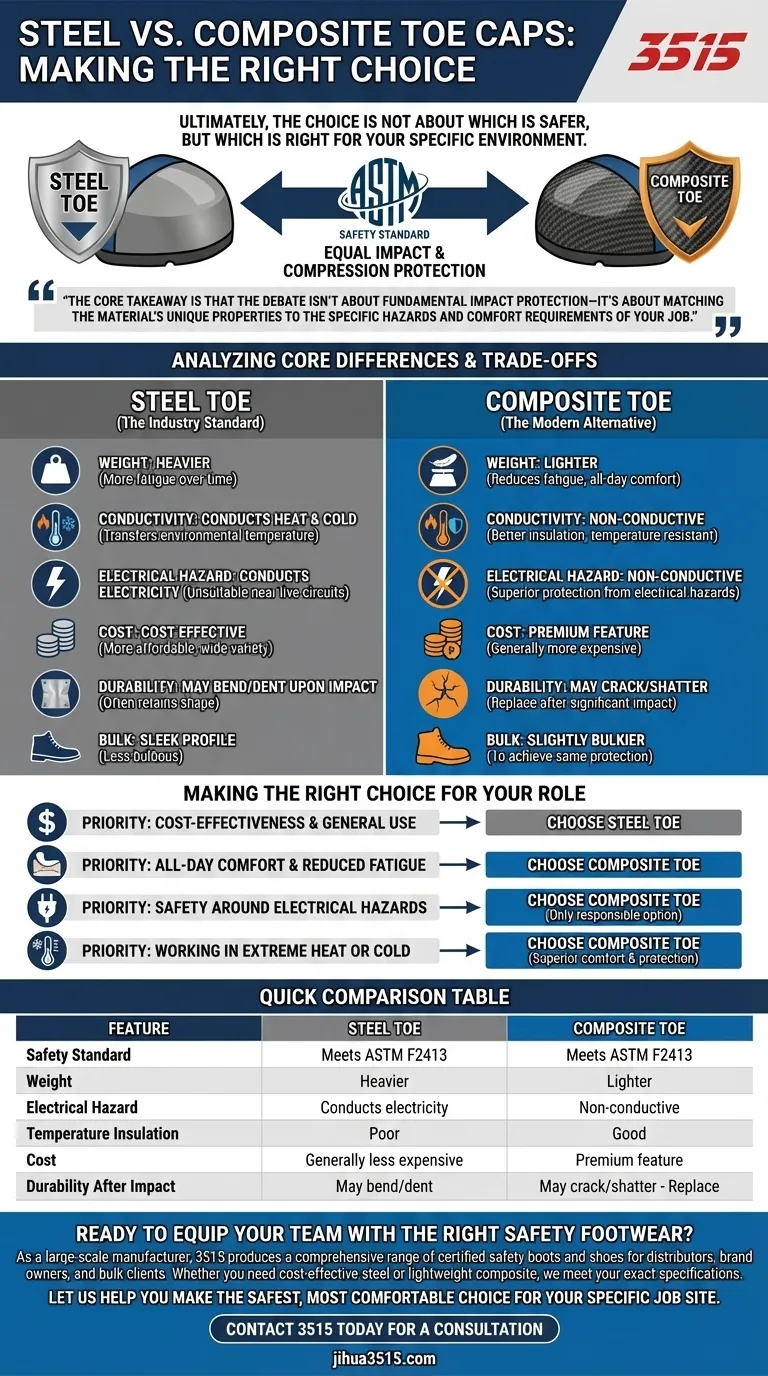

Ultimately, the choice is not about which is safer, but which is right for your specific environment. Both steel and composite toe caps are certified to meet the same ASTM F2413 safety standard for impact and compression protection. The decision hinges on secondary factors like weight, conductivity, and cost, which vary significantly between the two materials.

The core takeaway is that the debate isn't about fundamental impact protection—it's about matching the material's unique properties to the specific hazards and comfort requirements of your job.

The Foundation: Equal Safety Standards

The ASTM F2413 Mandate

Before comparing features, it's critical to understand that both steel and composite toe caps must pass the same rigorous testing to be sold as safety footwear.

The ASTM F2413 standard sets the minimum performance requirements for protective footwear. This means a certified composite toe boot has withstood the same level of impact and compression force as a certified steel toe boot.

Analyzing the Core Differences

Weight and All-Day Comfort

Composite toe caps are made from non-metal materials like carbon fiber, fiberglass, or Kevlar. This makes them significantly lighter than their steel counterparts.

For professionals who are on their feet all day, this weight reduction can translate directly to less fatigue and greater overall comfort.

Thermal and Electrical Conductivity

This is the most critical difference for many specialized roles. Steel is a natural conductor of energy.

Steel toe caps will transfer cold in freezing conditions and heat in hot environments, directly impacting comfort. More importantly, they conduct electricity, making them unsuitable for electricians or those working near live circuits.

Composite materials are non-conductive, offering superior protection from electrical hazards and better insulation against extreme temperatures.

Cost and Style Availability

Steel has been the industry standard for decades, making it a more mature and cost-effective technology.

Generally, steel toe boots are less expensive and are available in a much wider variety of styles and brands. Composite options are typically priced as a premium feature.

Understanding the Trade-offs

The Durability Question

While both meet the same impact standard, their response to force differs. Steel can bend or dent upon major impact but often retains its shape.

Some composite materials, however, may crack or shatter after one significant impact. For this reason, it is often recommended to replace composite toe footwear after a severe incident, as its structural integrity may be compromised.

The Bulk Factor

To achieve the same level of protection as steel, composite toe caps often need to be slightly thicker or bulkier.

While this doesn't affect safety, it can sometimes result in a more bulbous-looking toe box, which may be a consideration for style-conscious buyers.

Making the Right Choice for Your Role

To select the appropriate toe cap, evaluate your daily tasks and environment against the material's properties.

- If your primary focus is cost-effectiveness for general use: Steel toe remains the most reliable and budget-friendly choice.

- If your primary focus is all-day comfort and reduced fatigue: The lighter weight of a composite toe is a clear advantage.

- If your primary focus is safety around electrical hazards: Composite toe caps are the only appropriate and responsible option.

- If your primary focus is working in extreme heat or cold: A non-conductive composite toe will provide far superior comfort and protection.

Choosing the right safety boot means looking beyond the basic impact rating to find the material best suited for your daily work.

Summary Table:

| Feature | Steel Toe | Composite Toe |

|---|---|---|

| Safety Standard | Meets ASTM F2413 | Meets ASTM F2413 |

| Weight | Heavier | Lighter |

| Electrical Hazard | Conducts electricity | Non-conductive |

| Temperature Insulation | Poor (conducts heat/cold) | Good |

| Cost | Generally less expensive | Premium feature |

| Durability After Impact | May bend/dent | May crack/shatter (replace after major impact) |

Ready to Equip Your Team with the Right Safety Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety boots and shoes for distributors, brand owners, and bulk clients. Whether your workforce needs the cost-effective durability of steel toes or the lightweight, non-conductive advantages of composite toes, we have the production capabilities and expertise to meet your exact specifications.

Let us help you make the safest, most comfortable choice for your specific job site.

Contact 3515 today for a consultation to discuss your requirements and get a quote.

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium KPU Injection Athletic Style Safety Shoes

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- Why do people wear steel toe cap boots? The Ultimate Guide to Maximum Foot Protection

- Do steel toe boots increase the risk of trips and falls? How Quality Design Enhances Stability

- How does composite toe compare to steel toe? Choose the Right Safety for Your Job

- What are the impact and compression requirements for safety toe boots? Essential Standards for Worker Protection

- How can you quickly break in steel toe boots? A Fast, Pain-Free Method for Comfort

- What are the risks of wearing steel toe boots frequently? Avoid Foot Pain and Long-Term Injury

- Are composite toe boots as durable as steel toe boots? Find the Right Safety for Your Job

- Where are steel toe shoes commonly used? Essential Protection for High-Risk Industries