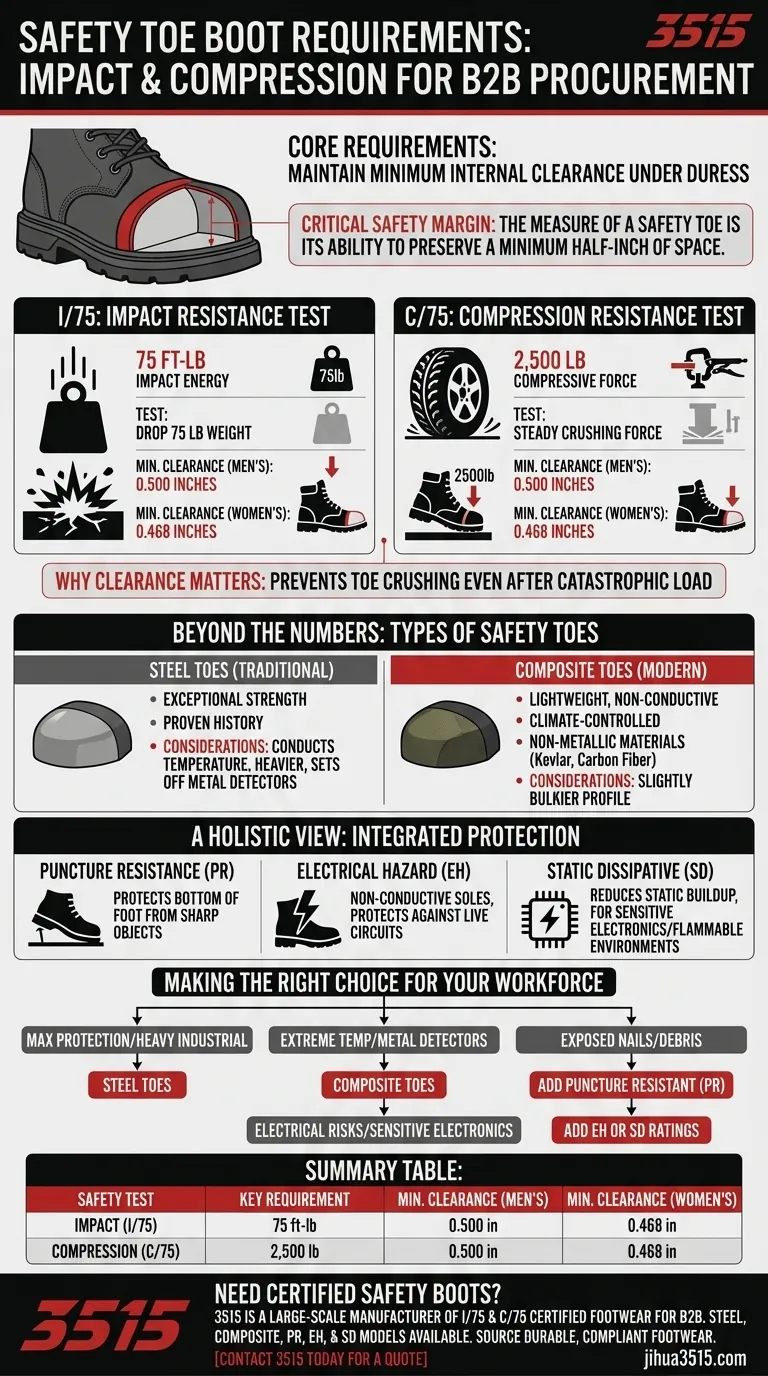

The core requirements for safety toe boots are defined by specific, standardized tests for impact and compression. To be compliant, a boot must maintain a minimum internal clearance after both a 75 foot-pound impact and the application of a 2,500-pound compressive force, ensuring a critical safety margin for the wearer's toes.

The specific force ratings are the baseline, but the true measure of a safety toe is its ability to preserve a minimum half-inch of space under duress. This clearance is the difference between a severe impact and a career-ending injury.

Deconstructing the Core Safety Ratings

To understand what makes a boot truly "safe," we must look at the two primary tests it must pass. These are often designated as I/75 and C/75 on a boot's certification label.

The Impact Resistance Test (I/75)

This test measures the toe cap's ability to protect against a sudden, heavy falling object. It involves dropping a 75-pound weight from a specified height to create an impact energy of 75 foot-pounds.

The boot passes only if it maintains a minimum internal clearance after the impact. This clearance is 0.500 inches for men's footwear and 0.468 inches for women's.

The Compression Resistance Test (C/75)

This test evaluates the toe cap's strength against a slow, crushing force, such as a vehicle tire rolling over the foot. It involves applying a steady force of 2,500 pounds to the toe area.

Like the impact test, the critical metric for passing is the remaining clearance. The toe cap must maintain 0.500 inches (men's) or 0.468 inches (women's) of space to be certified.

Why Clearance is the Critical Metric

The goal of these standards is not to prevent the safety toe from denting or deforming at all. The goal is to ensure that even if it deforms under a catastrophic load, it will not collapse far enough to crush the toes inside. This small, protected space is the essence of the safety standard.

Beyond the Numbers: Types of Safety Toes

Meeting these standards can be achieved with different materials, each offering a distinct profile of benefits. The two most common types are steel and composite.

Steel Toes: The Traditional Standard

Steel was the original material for safety toes and remains a highly effective option. It provides exceptional strength and has a long, proven history of protecting workers in the most demanding industrial environments.

Composite Toes: The Modern Alternative

Composite toes are made from non-metallic materials like Kevlar, carbon fiber, plastic, or fiberglass. They are engineered to meet the exact same I/75 and C/75 safety standards as steel toes but with different physical properties.

Understanding the Trade-offs

Neither steel nor composite is universally superior; the right choice depends entirely on the work environment and the wearer's needs.

Steel Toe Considerations

Because it is a metal, steel will conduct temperature, meaning boots can feel colder in winter and hotter in summer. Steel toes are also typically heavier than their composite counterparts and will set off metal detectors.

Composite Toe Considerations

Composite toes are significantly lighter, do not conduct electricity, and are "climate-controlled," as they don't transfer heat or cold. This makes them ideal for jobs requiring passage through metal detectors or work in extreme temperatures. However, they can sometimes have a slightly bulkier profile to achieve the same strength as steel.

A Holistic View of Foot Protection

The protective toe cap is just one component of a comprehensive safety footwear system. Many boots integrate other critical features to protect against a wider range of workplace hazards.

Puncture Resistance

A steel or non-metallic plate is placed in the midsole to protect the bottom of the foot from sharp objects like nails or scrap metal.

Electrical Hazard (EH)

An EH rating indicates the boot is designed with non-conductive soles and heels that can protect the wearer from accidental contact with live electrical circuits.

Static Dissipative (SD)

SD-rated footwear is designed to reduce the buildup of static electricity from the body. This is crucial for workers in highly sensitive electronics manufacturing or environments with flammable materials.

Making the Right Choice for Your Goal

Selecting the correct boot requires matching its certified features to the specific hazards you face.

- If your primary focus is maximum protection in a heavy industrial setting: Steel toes are the proven, traditional choice offering robust defense.

- If you work in extreme temperatures or pass through metal detectors: Lightweight composite toes provide certified protection without conducting heat, cold, or electricity.

- If you work around exposed nails or sharp debris: You must ensure your boot has a Puncture Resistant (PR) rating, regardless of the toe material.

- If you face electrical risks or work with sensitive electronics: Look beyond the toe cap for specific ratings like Electrical Hazard (EH) or Static Dissipative (SD).

Ultimately, choosing the right boot means matching its specific, certified protections to the real-world hazards of your job.

Summary Table:

| Safety Test | Key Requirement | Minimum Clearance (Men's) | Minimum Clearance (Women's) |

|---|---|---|---|

| Impact (I/75) | 75 ft-lb impact energy | 0.500 inches | 0.468 inches |

| Compression (C/75) | 2,500 lb compressive force | 0.500 inches | 0.468 inches |

Need certified safety boots that meet rigorous impact and compression standards? As a large-scale manufacturer, 3515 produces a comprehensive range of I/75 and C/75 certified footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots, including steel toe, composite toe, and models with additional protections like puncture resistance and electrical hazard ratings. Let us help you source durable, compliant footwear that protects your workforce. Contact 3515 today for a quote and discover the advantage of working with an experienced manufacturer.

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- High Performance Fire-Retardant Waterproof Safety Boots

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- How do safety boots provide toe protection? A Guide to Steel vs. Composite Caps

- What are steel toe work boots and what is their primary purpose? Essential Foot Protection for Hazardous Work

- What are the disadvantages of wearing steel-toe boots? Heavy Weight, Discomfort & Safety Risks

- What are the common problems with steel toe boots? How to Prevent Foot Pain & Fatigue

- What are the key features of women's safety toe work boots? Essential Protection for Hazardous Work

- What factors should be considered when choosing between composite toe and steel toe shoes? Select the Right Safety Footwear for Your Job

- Do steel toes perform as well as composite toes in extreme weather? A Guide to Thermal Regulation

- Are composite toe boots as durable as steel toe boots? Find the Right Safety for Your Job