In a direct comparison of material strength, no. Steel toe boots are inherently more durable and offer greater resistance to extreme crushing and impact forces than their composite counterparts. However, modern composite toe boots are engineered to meet the same stringent safety standards, and "durability" is only one critical factor in selecting the right protection for your work.

The choice between steel and composite toe boots is not about which is universally "better," but which provides the right balance of specific protections, weight, and environmental advantages for your unique job requirements.

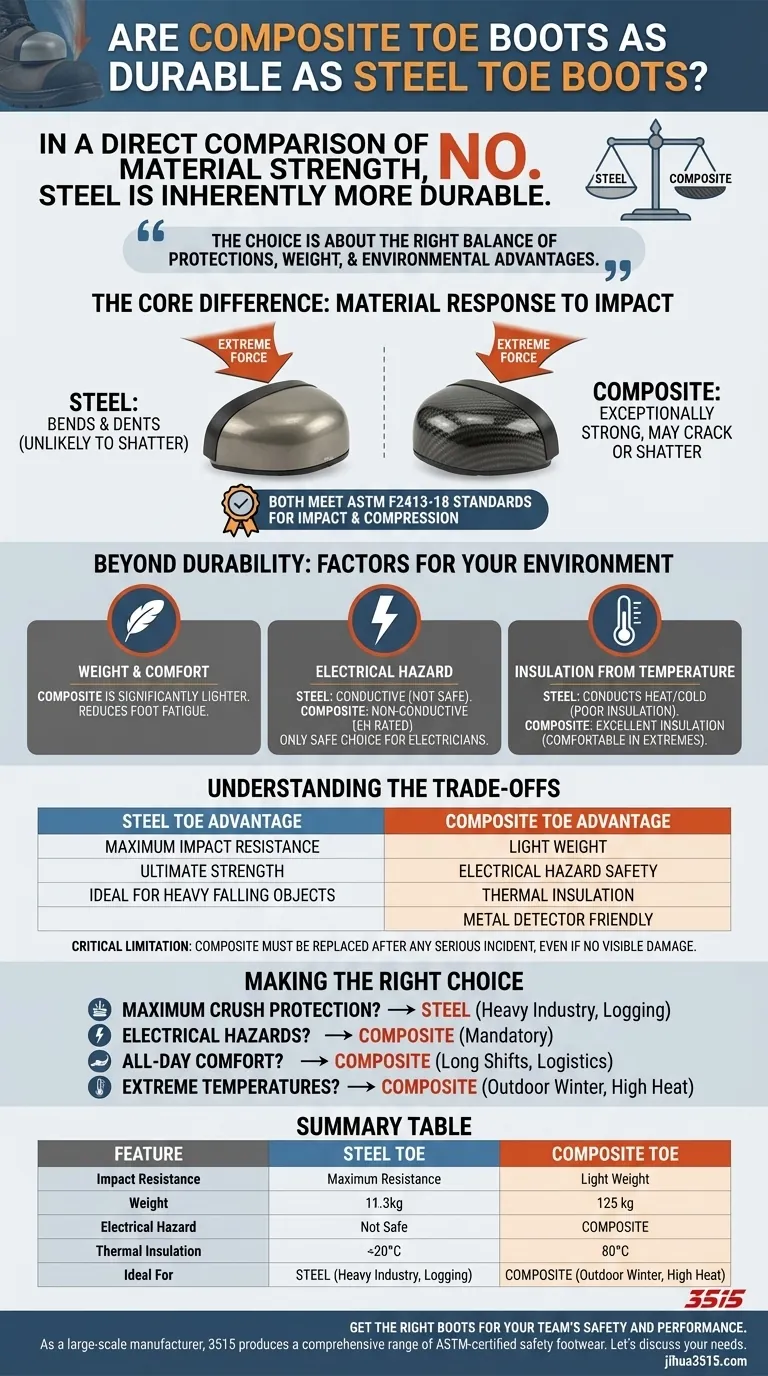

The Core Difference: Material Response to Impact

To understand durability, you must first understand how each material handles a significant force. Both types of boots are certified to protect you, but they achieve it in different ways.

How Steel Toes Handle Force

A steel toe cap is designed to withstand a very high level of impact and compression. When pushed beyond its structural limit, steel will typically bend and dent but is unlikely to shatter. This provides a high degree of ultimate protection against crushing.

How Composite Toes Handle Force

Composite toe caps are made from strong, non-metallic materials like carbon fiber, plastic, or Kevlar. They are exceptionally strong and can resist the same standard-level impacts as steel. However, under an extreme impact that exceeds their limits, they are more likely to crack or shatter.

The Role of Safety Standards

It is critical to know that for a boot to be sold as safety footwear, both steel and composite versions must meet the same ASTM F2413-18 standards for impact and compression resistance. This ensures a baseline level of proven protection, regardless of the material used.

Beyond Durability: Factors for Your Environment

The most durable boot is useless if it's wrong for your job. The "why" behind your choice often comes down to the unique conditions of your worksite.

Weight and All-Day Comfort

Composite toe boots are significantly lighter than steel toe boots. This reduction in weight minimizes foot fatigue over a long shift, which can directly contribute to greater comfort and productivity.

Electrical Hazard Protection

This is a non-negotiable factor. Steel is a conductor of electricity. Composite materials are not, making composite toe boots the only safe choice for electricians or anyone working in an environment with a risk of live electrical circuits.

Insulation from Temperature

Metal is an excellent thermal conductor, meaning steel toe caps get very cold in the winter and hot in the summer. Composite materials provide far superior insulation, keeping your feet more comfortable in extreme temperature environments.

Understanding the Trade-offs

Choosing the right boot means accepting a set of compromises. Being aware of them allows you to make an informed decision.

The Steel Toe Advantage

The primary benefits of steel are its maximum impact resistance and ultimate strength. In environments with a high risk of extremely heavy falling or rolling objects, steel offers the most robust protection.

The Composite Toe Advantage

The benefits of composite materials are their light weight, electrical hazard safety, and thermal insulation. They are also ideal for workplaces that require passing through metal detectors.

The Critical Limitation

After a significant impact, a composite toe cap's integrity may be compromised even if there is no visible damage. For this reason, they must be replaced after any serious incident. A steel toe boot with a minor dent may still be serviceable, though replacement is always the safest policy.

Making the Right Choice for Your Work

Evaluate your daily tasks and environment to determine your primary need.

- If your primary focus is maximum crush protection: In heavy industry, logging, or jobs with a high risk of falling objects, the superior strength of steel is the most reliable choice.

- If your primary focus is working around electrical hazards: Composite toe boots are the mandatory and only safe option for you.

- If your primary focus is all-day comfort and reduced fatigue: For long shifts in warehousing, logistics, or general trades, the lighter weight of composite boots is a significant advantage.

- If your primary focus is working in extreme temperatures: For outdoor work in winter or high-heat environments, the thermal insulation of composite boots will keep you safer and more comfortable.

By aligning the boot's material strengths with the demands of your job, you can ensure you have the right tool for optimal safety and performance.

Summary Table:

| Feature | Steel Toe Boots | Composite Toe Boots |

|---|---|---|

| Impact Resistance | Superior (bends/dents) | Meets ASTM Standards (may crack/shatter) |

| Weight | Heavier | Significantly Lighter |

| Electrical Hazard | Conductive (Not Safe) | Non-Conductive (EH Rated) |

| Thermal Insulation | Poor (conducts temperature) | Excellent (insulates) |

| Ideal For | Heavy industry, high crush risk | Electricians, long shifts, extreme temperatures |

Get the Right Boots for Your Team's Safety and Performance

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of steel toe and composite toe boots, ensuring you get durable, ASTM-certified protection perfectly suited to your specific work environment. We combine rigorous safety standards with superior comfort to enhance productivity and reduce fatigue.

Let's discuss your specific needs and get your team the right protection. Contact our experts today for a consultation and quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Durable Moc-Toe Wedge Work Boots | Wholesale Manufacturing for Brands

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What are the benefits of steel toe caps in work boots? Achieve Maximum Protection for Heavy-Duty Work

- What are the benefits of steel toe caps? Maximum Impact Protection & Durability

- What are the primary protective functions of safety shoes with steel toes in the automotive repair industry?

- Do steel toe boots increase the risk of trips and falls? How Quality Design Enhances Stability

- What are the main characteristics of steel-toe boots? Essential Safety Features Explained

- Why is it mandatory to wear safety shoes with steel toe protection during metal loading? Prevent Crushing Injuries

- When and where should steel toe boots be used? Ensure Maximum Impact Protection

- What are the most common types of safety toe caps? Choose the Right Protection for Your Job