Steel toe boots are a mandated safety standard in industries such as construction, manufacturing, and logistics. They are required in these fields for one primary reason: to provide critical, non-negotiable protection against severe foot injuries caused by the daily risk of falling objects, heavy rolling equipment, and sharp materials.

The use of steel toe boots is dictated not by an industry title alone, but by the presence of specific, high-impact and compression hazards. They represent the gold standard for protection in any environment where the threat of heavy falling or rolling objects is a constant reality.

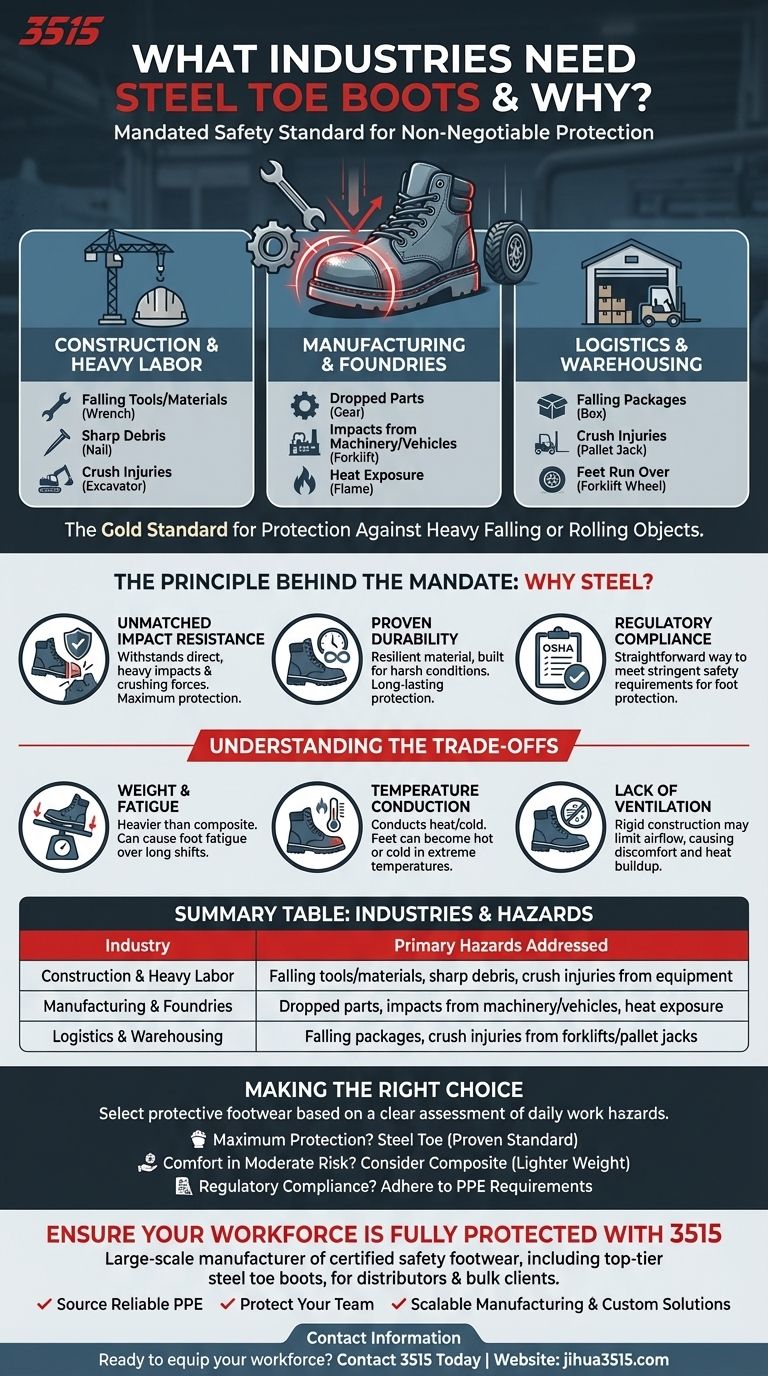

Core Industries and Their Specific Risks

Different work environments present unique dangers to the feet. Steel toe boots are the frontline defense against the most common and severe of these threats.

Construction and Heavy Labor

On construction sites, oil rigs, and remote mining locations, the hazards are constant and varied. Workers require protection from falling tools or building materials, sharp debris like nails and rebar on the ground, and the risk of crush injuries from heavy equipment.

Manufacturing and Foundries

Factory floors are dynamic environments with moving machinery, assembly lines, and heavy components being transported. Steel toes protect workers from dropped parts, impacts from carts or vehicles, and compression from machine parts. In specialized fields like welding or foundry work, they also shield against heat.

Logistics and Warehousing

In logistics, dock work, and warehousing, the primary risks come from both falling and rolling objects. Workers are protected from heavy packages falling from high shelves and the ever-present danger of feet being run over by forklifts, pallet jacks, and other material-handling equipment.

The Principle Behind the Mandate: Why Steel?

While other safety toe materials exist, steel has remained the industry benchmark for decades due to a few key principles of protection and practicality.

Unmatched Impact Resistance

The core function of a steel toe is to withstand direct, heavy impacts and crushing forces. Steel offers the maximum level of protection against these specific hazards, which are common in industrial settings. It is the most reliable material for preventing catastrophic foot injuries from heavy machinery or dropped loads.

Proven Durability

Steel is an incredibly durable and resilient material. Steel toe boots are built to withstand the harsh conditions of demanding workplaces, providing long-lasting protection day after day. This makes them a reliable and cost-effective choice for employers and workers alike.

Regulatory Compliance

Workplace safety is not optional. Regulatory bodies like the Occupational Safety and Health Administration (OSHA) mandate that employers provide Personal Protective Equipment (PPE) in hazardous areas. Steel toe boots are a straightforward way to meet these stringent safety requirements for foot protection.

Understanding the Trade-offs

While offering superior protection, the properties of steel also introduce trade-offs that are important to acknowledge.

Weight and Fatigue

Steel is significantly heavier than alternative materials like composite or alloy toes. Over a long shift, this added weight can contribute to foot fatigue and overall physical strain.

Temperature Conduction

As a metal, steel readily conducts temperature. In very cold environments, steel toe boots can become cold and draw heat away from the feet. Conversely, in extremely hot conditions, they can retain heat.

Lack of Ventilation

The rigid construction of many heavy-duty steel toe work boots can limit airflow. This lack of ventilation may lead to discomfort and heat buildup during extended periods of wear, especially in warm climates.

Making the Right Choice for Your Environment

Choosing the right safety boot requires a clear understanding of your specific work environment and its associated risks.

- If your primary focus is maximum protection from heavy objects: Steel toe boots are the proven industry standard for construction sites, factories, and warehouses with significant impact and compression risks.

- If your primary focus is comfort in moderate-risk areas: Acknowledge the weight and temperature trade-offs of steel; lighter composite materials may be a suitable choice if maximum impact resistance is not the absolute priority.

- If your primary focus is regulatory compliance: Always adhere to your employer's PPE requirements, as they have assessed the specific hazards for which steel toe protection is often mandated.

Ultimately, selecting the correct protective footwear is a critical decision based on a clear-eyed assessment of your daily work hazards.

Summary Table:

| Industry | Primary Hazards Addressed |

|---|---|

| Construction & Heavy Labor | Falling tools/materials, sharp debris, crush injuries from equipment |

| Manufacturing & Foundries | Dropped parts, impacts from machinery/vehicles, heat exposure |

| Logistics & Warehousing | Falling packages, crush injuries from forklifts/pallet jacks |

| Key Benefit | Unmatched impact resistance and proven durability for severe hazards |

Ensure Your Workforce is Fully Protected with 3515

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear, including top-tier steel toe boots, for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of industrial shoes and boots designed to meet and exceed safety standards.

Partner with us to:

- Source reliable PPE that meets stringent OSHA and industry regulations.

- Protect your team with durable footwear built for the toughest environments.

- Benefit from scalable manufacturing and custom solutions tailored to your needs.

Ready to equip your workforce with the best? Contact 3515 today to discuss your safety footwear requirements and get a quote.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Sport Style Safety Boots for Bulk Orders

People Also Ask

- Is it true that steel toes can cause toes to get cut off? Debunking the Dangerous Myth

- What industries are safety toe work boots best suited for? Protect Your Feet in High-Risk Environments

- Why choose composite toe boots over steel toe? Lighter, Non-Conductive & Metal Detector Safe

- What are the characteristics of a steel toe? Maximum Impact Protection Explained

- What factors should be considered when choosing between steel toe and composite toe boots?

- What are the impact and compression requirements for safety toe boots? Essential Standards for Worker Protection

- What are the disadvantages of wearing steel toe shoes? Weighing Protection Against Practicality

- What are the different types of safety toe shoes? Steel, Composite, or Alloy?