Choosing the right safety toe is a critical decision that goes far beyond simple preference. The primary factors to consider are the specific hazards of your workplace, including impact risk, electrical exposure, and extreme temperatures, as well as factors like boot weight, all-day comfort, and budget.

The choice between steel and composite toe boots is not about which is universally "better," but which material's specific properties provide the correct protection for your unique work environment. Steel offers maximum impact resistance, while composite provides a lighter, non-conductive alternative for specialized needs.

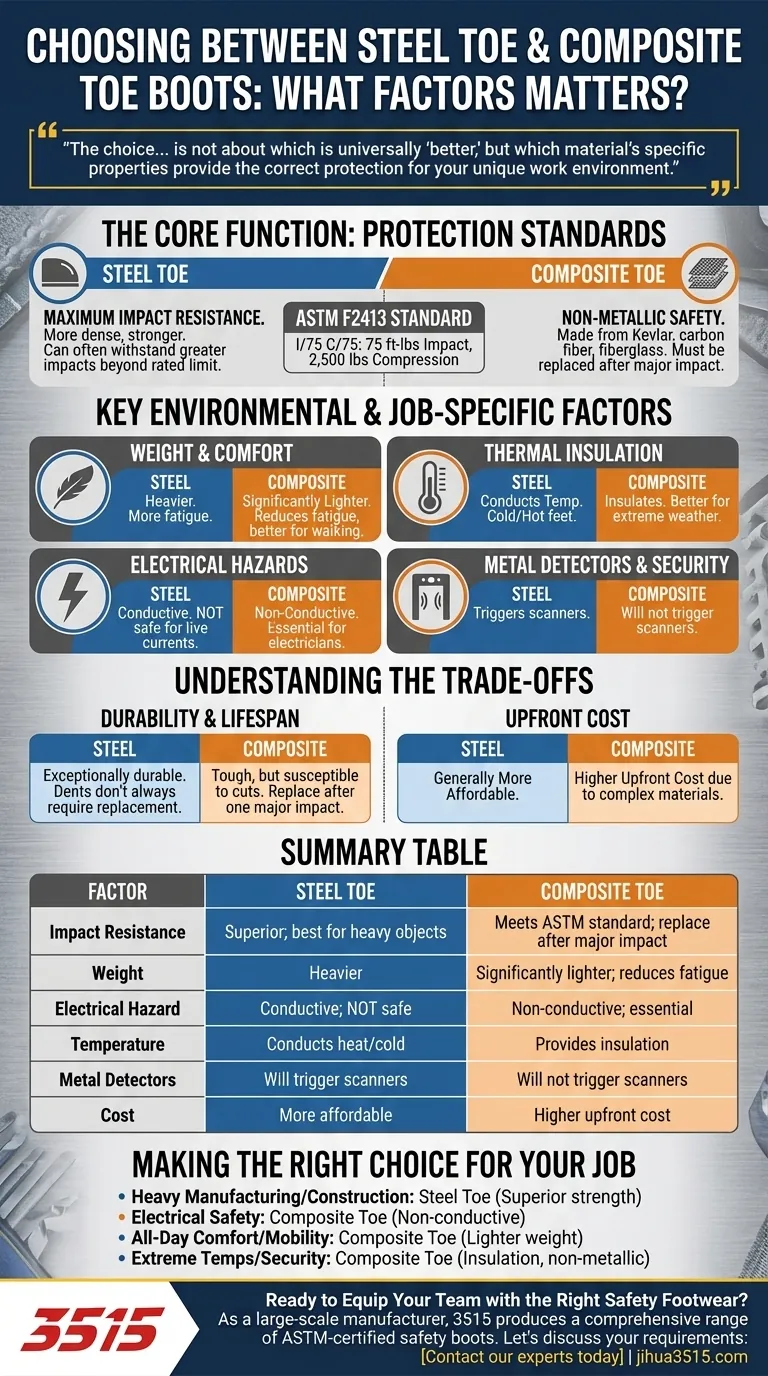

The Core Function: Protection Standards

At the heart of any safety boot is its ability to protect you from injury. Both steel and composite toe caps are regulated by the same safety standards, but their material properties dictate how they perform at the upper limits of that protection.

Understanding ASTM Ratings

Both steel and composite toe boots sold in the US must meet the ASTM F2413 standard for impact and compression resistance.

The common rating, I/75 C/75, signifies that the toe cap can withstand 75 foot-pounds of impact and 2,500 pounds of compression. This ensures a baseline level of certified safety for both materials.

Steel's Advantage: Maximum Impact Resistance

Steel is denser and stronger than composite materials. While both meet the minimum standard, a steel toe cap can often withstand greater impacts beyond the rated limit before catastrophic failure.

This makes steel the superior choice in environments with a high risk of extremely heavy falling or rolling objects, such as in heavy construction, logging, or industrial manufacturing.

Composite's Strength: Non-Metallic Safety

Composite toe caps are made from non-metal materials like Kevlar, carbon fiber, or fiberglass.

While they meet the same ASTM standards, they do not retain their structural integrity after a significant impact. If a composite toe takes a major hit, the boot must be replaced, as its protective capability is compromised.

Key Environmental and Job-Specific Factors

Beyond raw impact protection, the specific conditions of your job site will guide your decision. The differences in weight, conductivity, and insulation are often the deciding factors.

Weight and All-Day Comfort

Composite toe caps are significantly lighter than steel ones.

This weight reduction translates directly to less fatigue over a long workday, making composite a preferred option for workers who are constantly on their feet or cover long distances.

Thermal Insulation

Metal is an excellent conductor of temperature. Steel toes can become very cold in winter and hot in summer, transferring that uncomfortable temperature directly to your feet.

Composite materials are poor conductors, providing far better insulation. This makes them ideal for anyone working outdoors in extreme weather conditions.

Electrical Hazards

This is a critical, non-negotiable distinction. Because they contain no metal, composite toes are non-conductive and do not transfer electricity.

This makes them the only safe choice for electricians or anyone working in environments with a risk of live electrical currents. Steel toe boots should never be used in these situations.

Metal Detectors and Security

For workers in secure facilities, airports, or nuclear plants who must regularly pass through metal detectors, composite toes are essential.

Their non-metallic construction prevents the hassle of triggering security scanners, saving significant time and inconvenience.

Understanding the Trade-offs

Choosing a safety boot is an exercise in balancing priorities. Each material comes with inherent advantages and disadvantages related to its long-term use and cost.

Durability and Lifespan

Steel is exceptionally durable and can withstand minor bumps and scrapes without compromising its protective structure. A dent in a steel toe does not necessarily mean the boot needs to be replaced.

Composite materials, while tough, can be more susceptible to damage from cuts or gouges. As mentioned, they absolutely must be replaced after a single major compression or impact event.

The Upfront Cost

Generally, steel toe boots are more affordable than their composite counterparts.

The complex materials and manufacturing processes required for composite toe caps result in a higher price point, which may be a deciding factor depending on your budget.

Making the Right Choice for Your Job

To select the correct boot, analyze your daily risks and requirements with an objective eye. Your safety depends on matching the boot's features to your environment.

- If your primary focus is maximum impact protection (heavy manufacturing, construction): Steel toe is the definitive choice for its superior strength against crushing forces.

- If your primary focus is electrical safety: Composite toe is non-negotiable due to its non-conductive properties.

- If your primary focus is all-day comfort and mobility: Composite toe's lighter weight offers a significant advantage in reducing fatigue.

- If you work in extreme temperatures or pass through metal detectors: Composite toe provides the necessary thermal insulation and will not trigger security scanners.

Ultimately, selecting the correct safety toe is a critical decision based on a clear-eyed assessment of your daily work environment.

Summary Table:

| Factor | Steel Toe | Composite Toe |

|---|---|---|

| Impact Resistance | Superior; best for heavy objects | Meets ASTM standard; must be replaced after major impact |

| Weight | Heavier | Significantly lighter; reduces fatigue |

| Electrical Hazard | Conductive; NOT safe for live currents | Non-conductive; essential for electricians |

| Temperature | Conducts heat/cold | Provides insulation for extreme weather |

| Metal Detectors | Will trigger scanners | Will not trigger scanners |

| Cost | Generally more affordable | Higher upfront cost |

Ready to Equip Your Team with the Right Safety Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified safety boots for distributors, brand owners, and bulk clients. Whether your priority is maximum steel toe protection or the lightweight, non-conductive benefits of composite, we have the perfect solution for your workforce's specific hazards and comfort needs.

Let's discuss your requirements: Contact our experts today for a consultation and see how our production capabilities can deliver the exact footwear your business depends on.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

People Also Ask

- What are common complaints with steel toe boots? Solve Pain & Discomfort for Good

- How does an alloy toe compare to a steel toe? Lighter Weight, Same Protection

- What are the benefits of anti-fatigue mats for steel toe boot wearers? A Guide to Managing Workplace Comfort

- What is a steel-toe boot and what is its primary purpose? Essential Foot Protection for High-Risk Work

- How do composite-toe boots differ from steel-toe boots? A Guide to Choosing the Right Safety Footwear

- How should one decide whether to wear steel-toe boots at work? Assess Your Risks for Optimal Foot Safety

- Why are steel toe boots typically less comfortable than casual footwear? The Protection vs. Comfort Trade-off

- What are the advantages of steel toe shoes? Unmatched Protection for Industrial Work