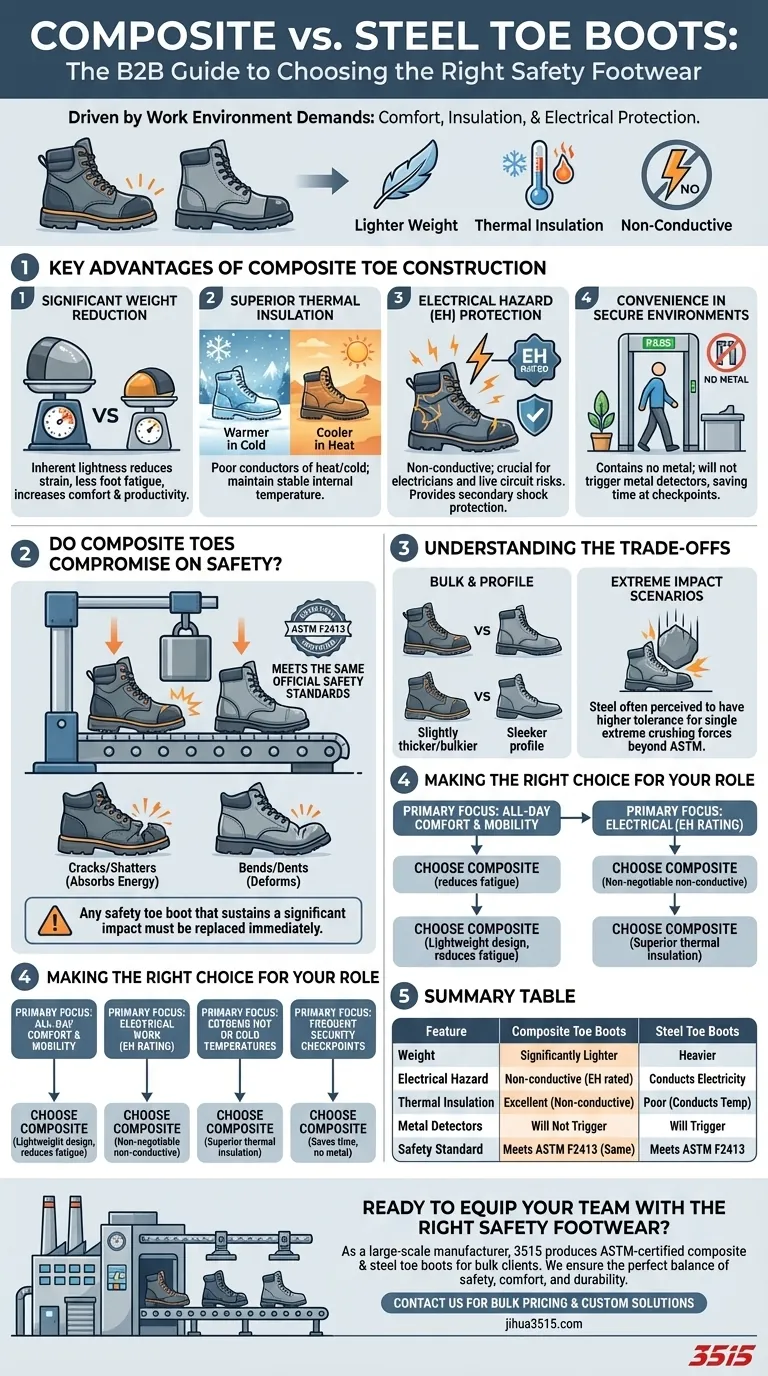

The choice between composite and steel toe boots is driven by the specific demands of your work environment. A worker might choose composite toe boots over traditional steel toes for three primary reasons: they are significantly lighter, they do not conduct electricity or temperature, and they won't set off metal detectors. These benefits provide a distinct advantage in comfort and safety for certain professions without sacrificing certified impact protection.

While both steel and composite toe boots are engineered to meet the same official safety standards, the decision hinges on your specific daily tasks. Composite toes excel where lightweight comfort, insulation from the elements, and electrical hazard protection are the most critical factors.

Key Advantages of Composite Toe Construction

The "composite" in composite toe refers to non-metallic materials like Kevlar, carbon fiber, and specialized plastics. This modern construction provides several functional benefits over traditional steel.

Significant Weight Reduction

Composite materials are inherently lighter than steel. This reduction in weight translates directly to less strain on your feet, legs, and back over the course of a long workday.

For professionals who are constantly moving, walking long distances, or climbing, this decreased weight can dramatically reduce fatigue and increase overall comfort and productivity.

Superior Thermal Insulation

Unlike metal, composite materials are poor conductors of heat and cold. This is a significant advantage for anyone working in extreme temperature environments.

In cold weather, composite toes help keep your feet warmer. In extreme heat, they will not heat up and transfer that heat to your feet, providing a more stable and comfortable internal temperature.

Electrical Hazard (EH) Protection

Perhaps the most critical advantage for certain trades is that composite materials do not conduct electricity. This makes them the default choice for electricians or anyone working in environments with a risk of contact with live circuits.

These boots often carry an Electrical Hazard (EH) rating, signifying they are designed to provide a secondary source of protection against accidental electrical shock.

Convenience in Secure Environments

Because they contain no metal, composite toe boots will not trigger metal detectors. This is a major practical benefit for workers who must pass through security checkpoints frequently, such as those in airports, government buildings, or secure facilities.

Do Composite Toes Compromise on Safety?

A common misconception is that "composite" means less protective. This is incorrect; the safety standard is the ultimate measure, not the material.

Meeting the ASTM Standard

To be sold as safety footwear, both composite and steel toe boots must meet the same ASTM F2413 standard for impact and compression resistance. A certified composite toe has been tested to withstand the exact same forces as a certified steel toe.

You are not choosing a "less safe" boot, but rather one whose material is better suited for specific environmental hazards beyond simple impact.

How Materials React to Impact

While both pass the standard, the materials behave differently under extreme stress. Steel is more likely to bend or dent upon a severe impact, whereas composite may crack or shatter.

Regardless of the material, any safety toe boot that has sustained a significant impact is compromised and must be replaced immediately to ensure your protection.

Understanding the Trade-offs

Choosing composite toe boots involves weighing their unique advantages against a few considerations where steel may still have an edge.

Bulk and Profile

To achieve the same level of ASTM-certified strength as steel, composite toe caps sometimes need to be slightly thicker or bulkier. This can make the toe box of the boot feel larger.

While modern designs have minimized this difference, steel can often provide the required protection in a slightly sleeker profile.

Extreme Impact Scenarios

Although both meet the minimum standard, steel is often perceived as having a higher tolerance for single, extreme crushing forces beyond the ASTM requirements. For heavy industrial work where the risk of massive falling objects is constant, some professionals still prefer the proven performance of steel.

Making the Right Choice for Your Role

Selecting the correct boot is about aligning the material's properties with the primary demands of your job.

- If your primary focus is all-day comfort and mobility: Choose composite for its lightweight design to minimize foot fatigue on long shifts with extensive walking.

- If your primary focus is electrical work or you need an EH rating: Composite is the non-negotiable choice for its non-conductive properties.

- If your primary focus is working in extreme hot or cold temperatures: Select composite for its superior thermal insulation and enhanced comfort.

- If your primary focus is frequent passage through security checkpoints: Composite will save you significant time and hassle by not triggering metal detectors.

By understanding these core differences, you can confidently select the safety footwear that truly supports your work.

Summary Table:

| Feature | Composite Toe Boots | Steel Toe Boots |

|---|---|---|

| Weight | Significantly lighter | Heavier |

| Electrical Hazard | Non-conductive (EH rated) | Conducts electricity |

| Thermal Insulation | Excellent (does not conduct heat/cold) | Poor (conducts temperature) |

| Metal Detectors | Will not trigger | Will trigger |

| Safety Standard | Meets ASTM F2413 (same as steel) | Meets ASTM F2413 |

Ready to equip your team with the right safety footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified composite and steel toe boots for distributors, brand owners, and bulk clients. Our production capabilities ensure you get the perfect balance of safety, comfort, and durability for your specific industry needs.

Contact us today for bulk pricing and custom solutions to protect your workforce.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Durable Moc-Toe Wedge Work Boots | Wholesale Manufacturing for Brands

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What are the primary benefits of steel toe boots? Maximum Impact Protection for Your Workforce

- What are the different types of safety toe shoes? Steel, Composite, or Alloy?

- In what work environments are steel-toe boots recommended? Essential Safety for High-Risk Industries

- What are the common safety toe types available in work shoes? Steel, Composite & Alloy Explained

- What tips can help ensure safe and comfortable use of steel toe boots? Master Fit, Support & Care

- What are the main reasons steel toe boots cause discomfort? Unlock All-Day Comfort & Safety

- What are the benefits of steel-toed shoes? Maximum Protection for Heavy-Duty Work

- What safety standards do modern steel toe boots adhere to? Understanding ASTM & EN ISO for Maximum Protection