At its core, a steel toe is a classic form of safety footwear featuring a heavy-duty steel cap built into the front of the shoe or boot. This reinforcement is engineered to provide robust protection against both impact from falling objects and compression from heavy rolling or stationary hazards.

The central characteristic of a steel toe is its unparalleled strength for impact protection. However, this heavy-duty nature comes with trade-offs in weight and conductivity that must be considered for your specific work environment.

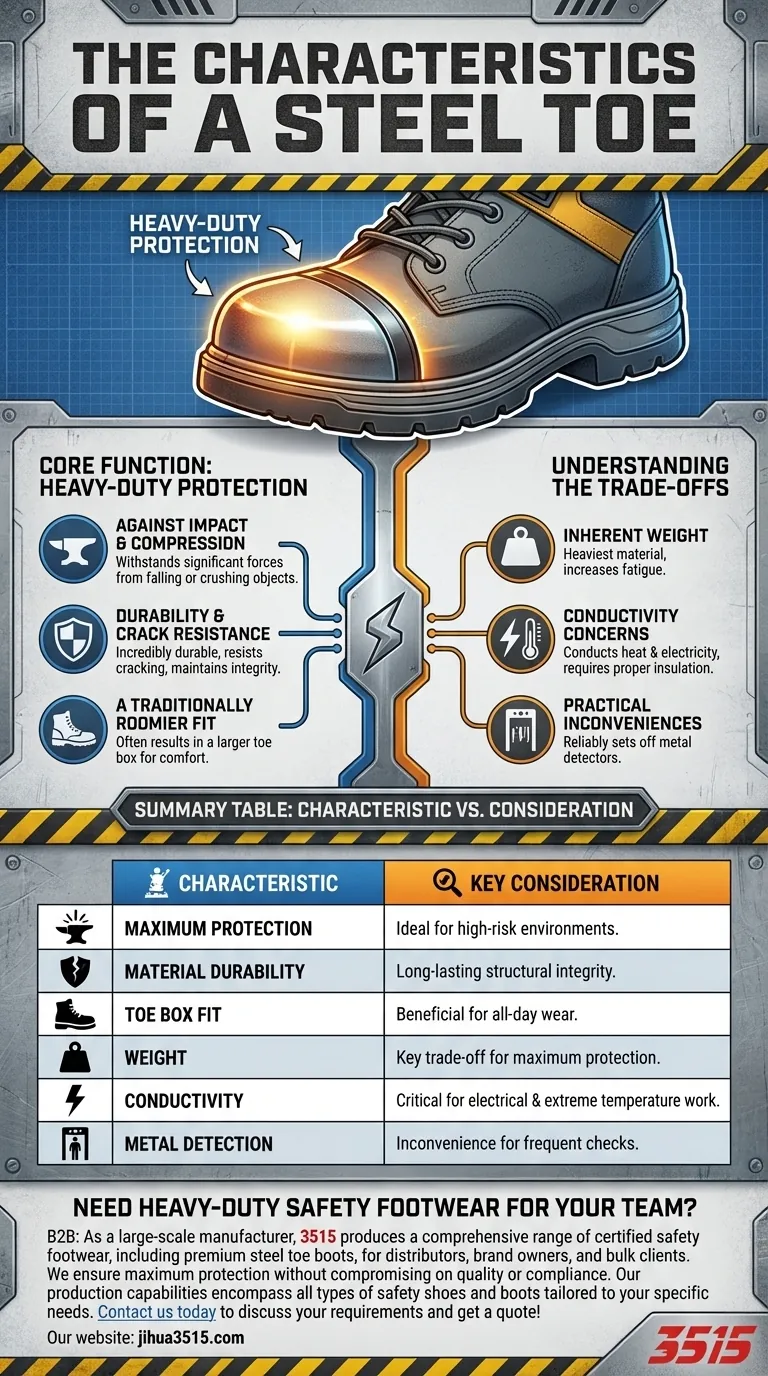

The Core Function: Heavy-Duty Protection

The primary reason for a steel toe's enduring popularity is its proven ability to protect the wearer in hazardous conditions. Its characteristics are rooted in the fundamental properties of steel.

Against Impact and Compression

A steel toe cap is designed to withstand significant forces. This makes it an essential safety feature for environments where objects might fall or where feet could be crushed by heavy equipment.

Durability and Crack Resistance

Steel is an incredibly durable material. This means a steel toe cap offers excellent resistance to cracking upon impact, maintaining its structural integrity when you need it most.

A Traditionally Roomier Fit

Steel safety caps often result in a larger toe box. For many wearers, this provides more room for their toes, which can contribute to greater comfort during a long workday.

Understanding the Trade-offs

While offering top-tier protection, the use of steel introduces several characteristics that can be disadvantages depending on the job.

Inherent Weight

Steel is the heaviest material used for safety toes. This added weight can lead to increased fatigue and may be less comfortable for those who spend extensive time walking or standing.

Conductivity Concerns

A critical characteristic of steel is that it conducts both heat and electricity. While properly insulated boots can be rated for electrical hazards, the steel component itself is conductive, a factor that requires careful consideration in certain environments.

Practical Inconveniences

As a metal, steel will reliably set off metal detectors. This can be a significant inconvenience for individuals who must frequently pass through security checkpoints.

Making the Right Choice for Your Needs

Understanding these core characteristics is key to selecting the appropriate footwear for your specific requirements.

- If your primary focus is maximum impact and compression protection: The heavy-duty, durable nature of steel makes it the traditional and most trusted standard.

- If your primary focus is all-day comfort and minimizing fatigue: The significant weight of a steel toe is a critical drawback to consider.

- If you work around live electrical circuits or in extreme temperatures: The conductive properties of steel mean you must verify the boot has the proper insulation and safety ratings for your specific hazard.

Ultimately, choosing a steel toe is a decision to prioritize proven, heavy-duty protection above all else.

Summary Table:

| Characteristic | Description | Key Consideration |

|---|---|---|

| Maximum Protection | Unparalleled strength against impact and compression from heavy objects. | Ideal for high-risk industrial environments. |

| Material Durability | Steel is highly durable and resistant to cracking upon impact. | Provides long-lasting structural integrity. |

| Toe Box Fit | Often results in a roomier toe box for increased comfort. | Can be beneficial for all-day wear. |

| Weight | Heaviest safety toe material, which can lead to fatigue. | A key trade-off for maximum protection. |

| Conductivity | Conducts heat and electricity; requires proper insulation. | Critical for electrical hazard and extreme temperature work. |

| Metal Detection | Will set off metal detectors. | An inconvenience for sites with frequent security checks. |

Need Heavy-Duty Safety Footwear for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear, including premium steel toe boots, for distributors, brand owners, and bulk clients. We ensure maximum protection without compromising on quality or compliance.

Our production capabilities encompass all types of safety shoes and boots tailored to your specific needs.

Contact us today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Durable Steel Toe Safety Boots Wholesale & Custom Manufacturing

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

People Also Ask

- What physical protections are provided by the S1 standard and integrated steel toecaps in industrial safety boots? Ensure Ultimate Foot Safety & Hazard Protection

- What are the primary protective functions of safety shoes with steel toes in the automotive repair industry?

- What are the primary protective roles of safety shoes for mosquito control? Safeguard Workers from Chemical & Field Risks

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- How do abrasion-resistant work boots extend equipment service life? Maximize Durability in Harsh Outdoor Environments