In short, composite toe work boots are most common in industries where workers need protection without the weight or conductivity of metal. This includes roles for general tradespeople, mobile workers, electricians, and personnel in logistics, security, or transportation who frequently pass through metal detectors.

The decision to use composite toe boots is driven less by a specific industry and more by the specific job requirements. If a role demands lightweight comfort for long hours, protection from electrical hazards, or non-metallic footwear, composite toe is the superior choice over traditional steel.

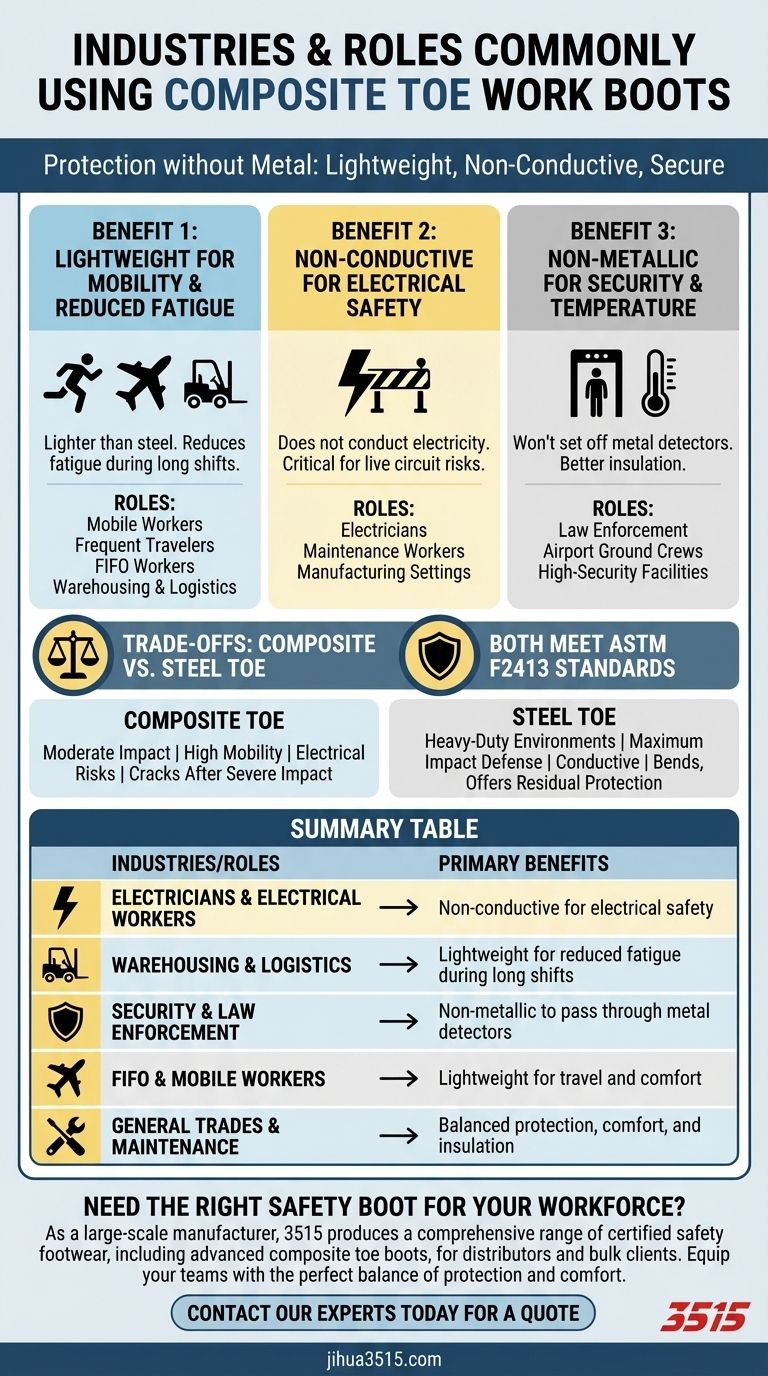

Why Specific Roles Demand Composite Toe Protection

The primary advantage of a composite toe boot lies in its material composition. Instead of steel, the protective cap is made from a blend of non-metal materials like Kevlar, carbon fiber, fiberglass, and plastic. This creates a unique set of benefits tailored to specific work environments.

Benefit 1: Lightweight for Mobility and Reduced Fatigue

Composite materials are significantly lighter than steel. Over the course of a long shift with thousands of steps, this weight difference reduces fatigue and increases comfort.

This makes them ideal for mobile workers, frequent travelers, and FIFO (Fly-In, Fly-Out) workers. It's also a major benefit for those in warehousing and logistics who are constantly on their feet.

Benefit 2: Non-Conductive for Electrical Safety

Because they contain no metal, composite toe caps do not conduct electricity. This is a critical safety feature for any job with a risk of contact with live circuits.

Electricians and maintenance workers in manufacturing settings often choose composite toe boots specifically for this reason, as it provides an essential layer of protection against electrical hazards.

Benefit 3: Non-Metallic for Security and Temperature

The absence of metal means these boots won't set off metal detectors, making them highly practical for workers who need to pass through security checkpoints frequently.

This is a key advantage for law enforcement, airport ground crews, and workers in high-security facilities. Additionally, composite materials do not conduct heat or cold as readily as steel, offering better insulation in extreme temperature environments.

Understanding the Trade-offs: Composite vs. Steel Toe

While composite toe boots offer clear advantages, they are not universally superior to steel toe boots. The right choice depends on a clear understanding of the trade-offs.

Protection Standards

Both composite and steel toe boots must meet the same ASTM F2413 standards for impact and compression resistance. A common misconception is that composite is weaker; a certified boot offers certified protection, regardless of material.

However, steel can often withstand a higher level of impact and compression beyond the minimum standard. After a single, severe impact, a composite toe may crack and must be replaced, whereas a steel toe might bend but still offer some protection.

Environment and Hazard Level

Steel toe boots remain the standard in heavy-duty environments like construction, heavy manufacturing, and logging. Their ability to handle extreme impacts from heavy objects or machinery makes them the most reliable choice where foot injuries are a significant and constant risk.

Composite toe boots, on the other hand, excel where the primary hazards are moderate impacts, electrical risks, or where worker mobility and comfort are paramount for job performance.

Making the Right Choice for Your Role

Choosing the right safety boot requires matching its features to your daily tasks and potential hazards.

- If your primary focus is electrical safety or passing through metal detectors: A composite toe boot is the only logical choice.

- If your primary focus is maximum impact protection in a heavy industrial or construction zone: A steel toe boot offers the highest level of defense against crushing force.

- If your primary focus is all-day comfort, mobility, and reduced fatigue: A composite toe boot will provide certified protection with significantly less weight.

Ultimately, understanding the material science behind your safety gear empowers you to select the precise tool for the job.

Summary Table:

| Industry/Role | Primary Benefit of Composite Toe |

|---|---|

| Electricians & Electrical Workers | Non-conductive for electrical safety |

| Warehousing & Logistics | Lightweight for reduced fatigue during long shifts |

| Security & Law Enforcement | Non-metallic to pass through metal detectors |

| FIFO & Mobile Workers | Lightweight for travel and comfort |

| General Trades & Maintenance | Balanced protection, comfort, and insulation |

Need the right safety boot for your workforce?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear, including advanced composite toe boots, for distributors, brand owners, and bulk clients. We can help you equip your teams with the perfect balance of protection, comfort, and job-specific features.

Contact our experts today to discuss your requirements and get a quote.

Visual Guide

Related Products

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What role do safety shoes play within HIRADC in open-pit mining? The Ultimate Guide to Final-Line Risk Control

- What are the two types of electrical protection offered by safety boots? Anti-Static vs. EH Explained

- What industries besides construction require durable and protective footwear for women? Key Sectors Explained

- What features should manufacturing workers consider for comfort in their protective footwear? Prioritize Support & Safety

- What is the significance of MTBF in footwear maintenance? Optimize Reliability and Safety with Data

- How does using a shoehorn help maintain work shoes? Extend Your Shoe's Lifespan & Value

- What quality control measures are taken in safety shoes manufacturing? Ensure Maximum Protection & Compliance

- Why are functional socks made of moisture-wicking materials essential? Boost Comfort in Occupational Protective Footwear