Using a shoehorn is the most critical step in preserving the structural integrity of your work shoes. It acts as a guide, allowing your heel to slide smoothly into place without crushing the shoe's back. This simple action directly prevents the breakdown of the heel, which is essential for both the shoe's appearance and its supportive function.

A shoehorn is not a tool of convenience; it is a tool of preservation. It protects the shoe's rigid heel counter from the cumulative damage of being crushed, ensuring your work shoes retain their intended shape, support, and professional appearance for years to come.

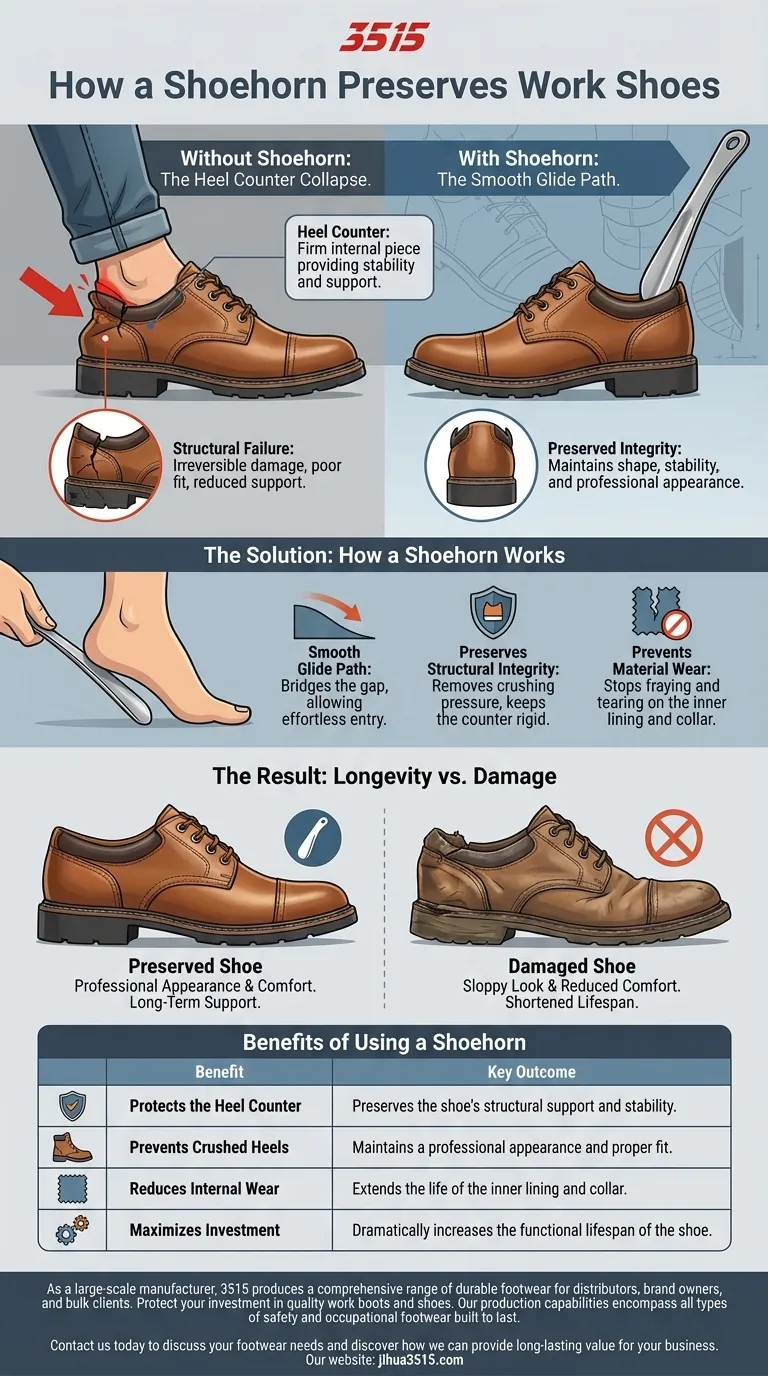

The Core Problem: A Damaged Heel Counter

The primary benefit of a shoehorn is its ability to protect a single, critical component of your shoe's construction. Understanding this part is key to understanding the value of the tool.

What is the Heel Counter?

The heel counter is a firm, internal piece of material built into the back of a shoe. Its purpose is to cup your heel, providing stability and preventing your foot from rolling. It is the architectural foundation of the shoe's rear.

The Damage of Forcing Your Foot In

When you jam your foot into a shoe, you are bending and crushing this heel counter. The repeated force causes it to crease, soften, and eventually collapse entirely. This damage is irreversible.

Consequences of a Broken Counter

A collapsed heel counter does more than just make a shoe look sloppy and worn. It signifies a structural failure. The shoe loses its ability to support your ankle, leading to a poor fit, reduced comfort, and a significant decrease in the footwear's functional lifespan.

How a Shoehorn Provides the Solution

A shoehorn works by fundamentally changing how your foot enters the shoe, eliminating the destructive force that causes damage.

Creating a Smooth Glide Path

The shoehorn provides a smooth, low-friction ramp for your heel. It bridges the gap between your heel and the back of the shoe, allowing your foot to slide in effortlessly.

Preserving Structural Integrity

By providing this glide path, the shoehorn completely removes the crushing pressure on the heel counter. The counter is never bent or stressed, so it remains rigid and effective for the entire life of the shoe.

Preventing Material Wear

Beyond the structural counter, using a shoehorn also prevents premature wear on the soft inner lining and the padded collar at the top of the shoe. This stops the fraying and tearing that often results from forcing a foot into place.

Why This Simple Step is Often Ignored

Despite the clear benefits, many people neglect to use a shoehorn. Understanding the perceived obstacle is the first step to overcoming it.

The "Inconvenience" Factor

The most common reason for not using a shoehorn is that it feels like an unnecessary extra step. However, this perceived inconvenience, which takes less than five seconds, should be weighed against the significant cost of prematurely replacing expensive work shoes.

Lack of Awareness

Many simply do not realize the permanent damage they are causing. They see the crushed back of a shoe as a normal sign of wear and tear, not as the result of a preventable habit. Consistent use of a shoehorn is the difference between a shoe that wears out and one that is destroyed.

Making Your Investment Last

Integrating a shoehorn into your daily routine is a simple decision with long-term benefits. Your choice depends on what you value most in your footwear.

- If your primary focus is a professional appearance: A shoehorn is non-negotiable to prevent the collapsed, unprofessional look of a crushed heel.

- If your primary focus is long-term comfort and support: Protecting the heel counter ensures your shoe continues to provide the stability and proper fit it was designed for.

- If your primary focus is maximizing the value of your purchase: This simple tool is the most effective way to dramatically extend the functional life of your work shoes.

By making a shoehorn a permanent part of putting on your shoes, you are actively choosing to preserve their quality and longevity.

Summary Table:

| Benefit | Key Outcome |

|---|---|

| Protects the Heel Counter | Preserves the shoe's structural support and stability. |

| Prevents Crushed Heels | Maintains a professional appearance and proper fit. |

| Reduces Internal Wear | Extends the life of the inner lining and collar. |

| Maximizes Investment | Dramatically increases the functional lifespan of the shoe. |

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Protect your investment in quality work boots and shoes. Our production capabilities encompass all types of safety and occupational footwear built to last. Contact us today to discuss your footwear needs and discover how we can provide long-lasting value for your business.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?