At its core, quality control in safety shoe manufacturing is a multi-stage process that goes far beyond a simple final inspection. It involves rigorous testing of raw materials before production, continuous monitoring during assembly, and a battery of standardized physical tests on the finished product to verify its protective capabilities against specific workplace hazards.

The true measure of a safety shoe's quality isn't just its final appearance, but the documented, verifiable process that ensures every component—from the steel toe to the outsole—meets or exceeds established international safety standards like ASTM or EN ISO.

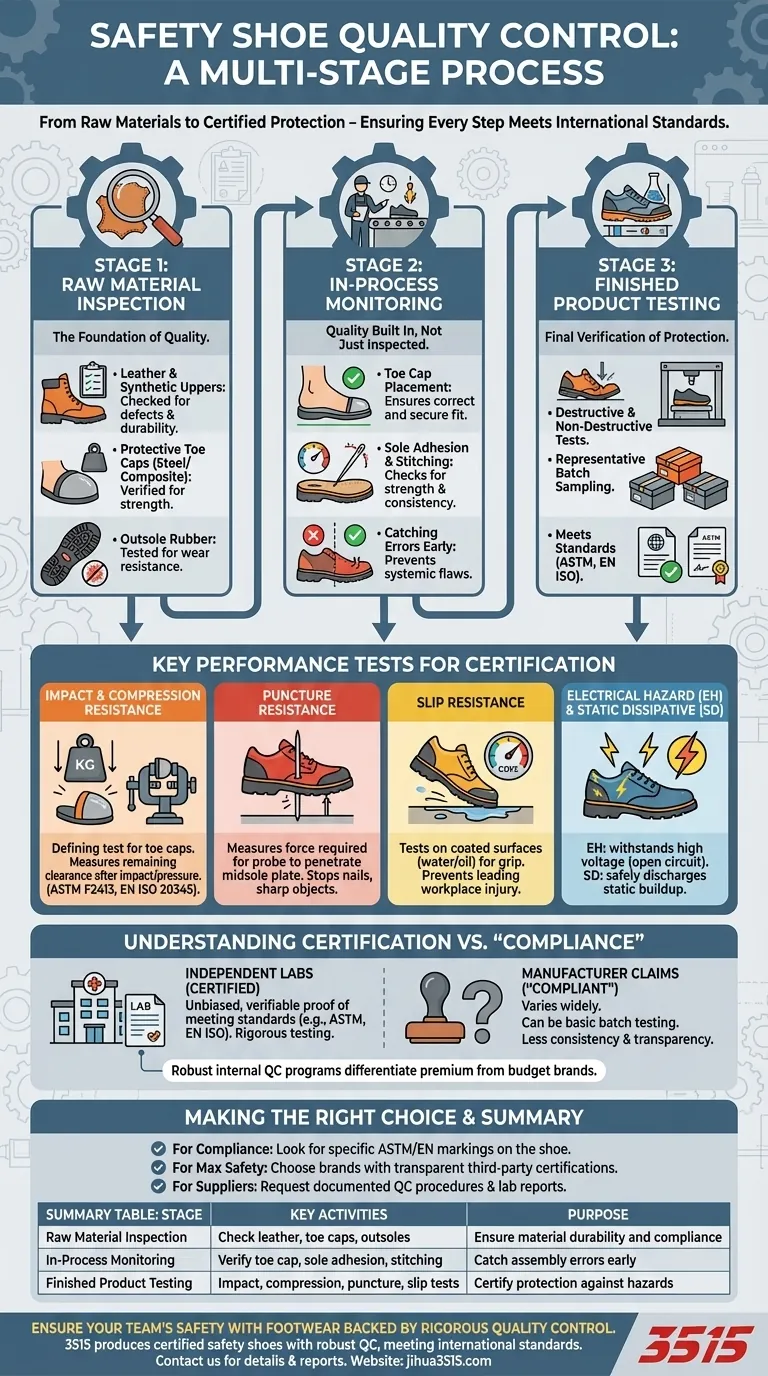

The Three Pillars of Safety Shoe QC

A robust quality control system is not a single event but a continuous process. It is integrated into the manufacturing lifecycle from start to finish to ensure the final product is consistently safe and reliable.

Stage 1: Raw Material Inspection

Before a single shoe is assembled, every component must be verified. This is the foundation of quality.

Key materials like leather, synthetic uppers, steel or composite toe caps, and rubber for outsoles are inspected for defects, durability, and compliance with specifications. A weak raw material cannot produce a strong safety shoe.

Stage 2: In-Process Monitoring

Quality is built in, not just inspected at the end. Technicians monitor critical steps during the assembly line.

This includes verifying the correct and secure placement of the protective toe cap, ensuring proper adhesion of the sole to the upper, and checking stitching for strength and consistency. Catching errors here prevents systemic flaws in a batch.

Stage 3: Finished Product Testing

Once the shoe is fully assembled, it undergoes a series of destructive and non-destructive tests based on the standards it is designed to meet. This is the final verification of its protective features.

These tests are performed on a representative sample from each production batch using specialized lab equipment.

Key Performance Tests for Certification

These are not arbitrary checks; they are highly standardized tests designed to simulate real-world workplace hazards. The specific tests performed depend on the safety ratings the shoe is designed to achieve (e.g., impact resistance, puncture resistance).

Impact & Compression Resistance

This is the defining test for the protective toe cap. A specialized machine drops a heavy weight onto the toe cap to test for impact resistance. Another machine applies slow, immense pressure to test for compression resistance. The clearance remaining inside the cap after the test determines if it passes.

Puncture Resistance

For shoes with this feature, a steel probe is forced through the sole at a specified speed and force. The test measures the force required to penetrate the protective midsole plate, ensuring it can stop a nail or other sharp object underfoot.

Slip Resistance

The shoe is placed on various surfaces (like steel or tile) coated with contaminants (like water or oil). The machine measures the coefficient of friction to determine the outsole's ability to prevent slips, which is a leading cause of workplace injury.

Electrical Hazard (EH) & Static Dissipative (SD)

For EH-rated shoes, the footwear is tested to ensure it can withstand the application of a high voltage without significant current flow, protecting the wearer from open circuits. SD-rated shoes are tested for their ability to safely discharge static electricity buildup.

Understanding the Trade-offs: Certification vs. "Compliance"

Not all quality control claims are equal. The distinction between a shoe that is independently certified and one that simply claims to "meet the standards" is critical for ensuring safety.

The Role of Independent Labs

The most reputable manufacturers submit their products to third-party laboratories for testing. This provides unbiased, verifiable proof that the footwear meets the specific safety standards claimed, such as ASTM F2413 in the United States or EN ISO 20345 in Europe.

Why Manufacturer Processes Vary

While the standards are fixed, a manufacturer's internal QC process can range from basic batch testing to advanced statistical process control. A more rigorous internal program leads to greater consistency and a lower probability of a defective product reaching the market. This is often a key differentiator between premium and budget brands.

Making the Right Choice for Your Goal

Understanding the QC process allows you to select footwear based on verifiable safety rather than just features.

- If your primary focus is workplace compliance: Look for the specific ASTM or EN standard marking printed or stitched on the shoe's tongue or collar.

- If your primary focus is maximum personal safety: Choose brands that are transparent about their third-party certifications and have a long-standing reputation for quality manufacturing.

- If you are evaluating suppliers for your team: Ask for documentation of their QC procedures and copies of independent lab test reports for the models you are considering.

Ultimately, robust quality control is the invisible engineering that transforms a regular boot into a trusted piece of personal protective equipment.

Summary Table:

| Stage | Key Activities | Purpose |

|---|---|---|

| Raw Material Inspection | Check leather, toe caps, outsoles for defects | Ensure material durability and compliance |

| In-Process Monitoring | Verify toe cap placement, sole adhesion, stitching | Catch assembly errors early |

| Finished Product Testing | Impact, compression, puncture, slip resistance tests | Certify protection against workplace hazards |

Ensure your team's safety with footwear backed by rigorous quality control. As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety shoes and boots for distributors, brand owners, and bulk clients. Our robust QC process, from material inspection to final testing, guarantees every pair meets international standards like ASTM F2413 and EN ISO 20345. Contact us today to discuss your safety footwear needs and receive detailed test reports.

Visual Guide

Related Products

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Wholesale Leather Safety Boots with Customizable Protective Toe

People Also Ask

- How do safety shoes with reinforced toe protection and puncture-resistant midsoles serve as a physical barrier?

- What are the primary safety functions of safety boots with steel-toe designs? Essential Protection for Industry

- Why is the use of steel-toe safety footwear critical during the maintenance of sugar factory press chains? Protect Your Team

- Why is the use of specialized work boots with high comfort levels necessary for welding? Enhance Safety and Endurance

- Why are industrial safety shoes necessary for mining machinery maintenance? Protect Feet from Crushing and Punctures