At a glance, men's work shoes are essential in industries like construction, manufacturing, agriculture, oil and gas, and electrical work. These environments demand dependable footwear designed to protect against specific, often severe, workplace hazards and enhance overall performance.

The suitability of a work shoe is defined not by the industry title, but by its specific safety features and how they directly counter the unique hazards present in a particular job environment.

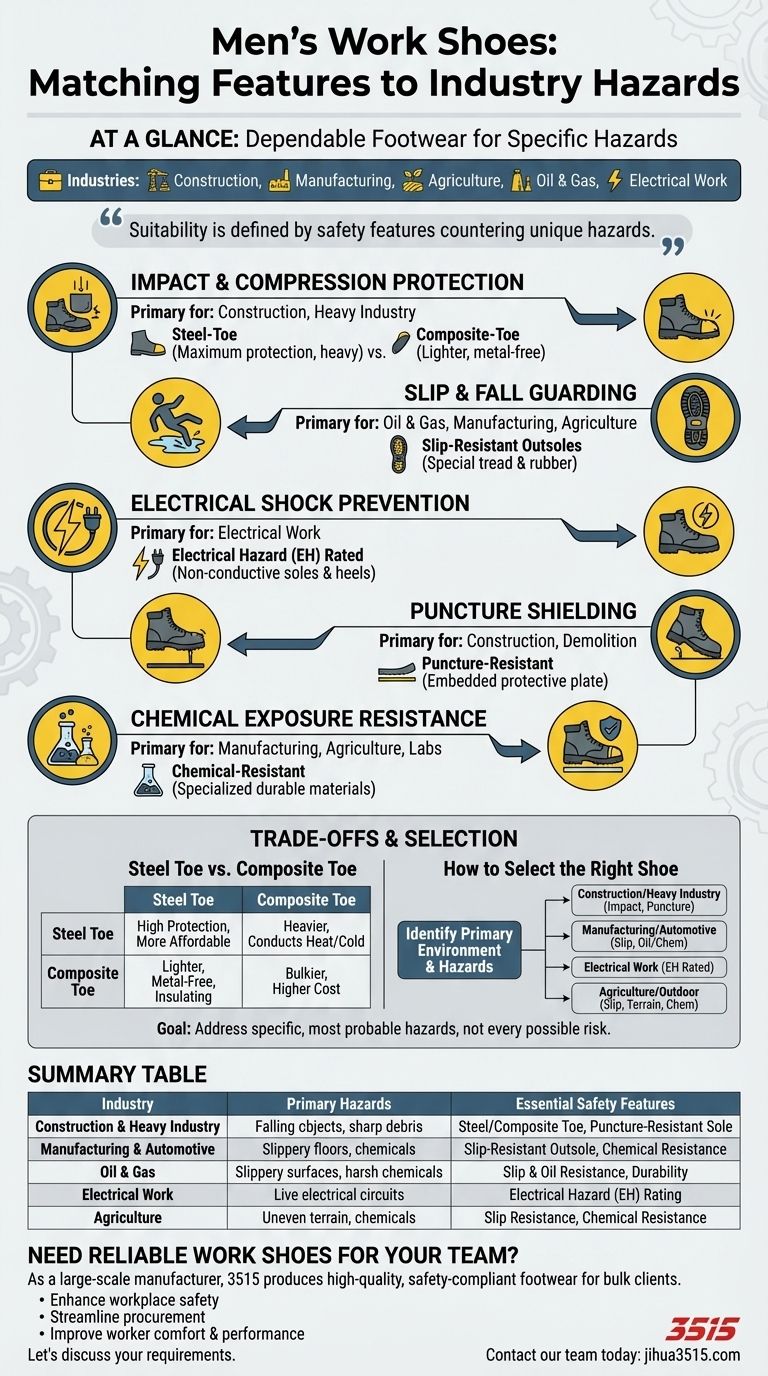

Matching Shoe Features to Industry Hazards

The most effective way to determine the right work shoe is to analyze the risks of the job and match them to the corresponding protective technology built into the footwear.

Protection Against Impact and Compression

In settings with heavy machinery, falling objects, or rolling equipment, protecting the toes is paramount. This is a primary requirement in construction and industrial manufacturing.

Steel-toe boots provide maximum protection against heavy impacts. Composite-toe boots offer a lighter, metal-free alternative that still meets safety standards.

Guarding Against Slips and Falls

Slippery surfaces are a common hazard in many fields, from factory floors to outdoor sites. These conditions are prevalent in the oil and gas, manufacturing, and agricultural industries.

Shoes with slip-resistant outsoles are engineered with special tread patterns and rubber compounds to provide superior traction on wet, oily, or slick surfaces.

Preventing Electrical Shocks

For electricians or anyone working near live electrical circuits, footwear must provide insulation against electrical currents.

Electrical Hazard (EH) rated shoes are constructed with non-conductive soles and heels to protect the wearer from accidental contact with live electrical circuits.

Shielding from Punctures

Job sites are often littered with sharp objects like nails, screws, and other debris that can easily pierce a standard sole. This is a significant risk in construction and demolition.

Puncture-resistant shoes have a protective plate, often made of steel or a flexible composite material, embedded in the midsole to block sharp objects from penetrating the foot.

Resisting Chemical Exposure

In certain manufacturing, agricultural, or laboratory settings, workers may be exposed to corrosive or hazardous substances that can degrade footwear and harm the skin.

Chemical-resistant boots are made from specialized materials designed to withstand exposure to specific chemicals, oils, and acids without breaking down.

Understanding the Trade-offs in Work Shoe Selection

Choosing the right work shoe often involves balancing competing factors. A shoe that excels in one area may have drawbacks in another.

Steel Toe vs. Composite Toe

Steel toes typically offer the highest level of impact protection and are often more affordable. However, they are heavier and can conduct cold or heat.

Composite toes are significantly lighter, do not conduct temperature, and are ideal for metal-free work environments. They can, however, be slightly bulkier than steel to achieve the same safety rating.

The Cost of Over-Protection

Selecting a boot with every conceivable safety feature is not always the best strategy. A highly specialized boot can be heavy, inflexible, and expensive.

The goal is to identify the specific, most probable hazards of your job and select a shoe that addresses them directly, rather than choosing one that protects against every possible risk.

How to Select the Right Work Shoe

Use your primary work environment as the starting point to identify the non-negotiable features you need.

- If your primary focus is construction or heavy industry: Prioritize impact protection (steel/composite toe) and puncture resistance.

- If your primary focus is manufacturing or automotive: Look for slip-resistant outsoles and assess the need for oil or chemical resistance.

- If your primary focus is electrical work: Ensure your shoes are explicitly Electrical Hazard (EH) rated to protect against shock.

- If your primary focus is agriculture or outdoor work: Combine slip resistance with features that handle uneven terrain and potential chemical exposure.

Ultimately, choosing the right work shoe is a critical decision based on a clear understanding of your daily tasks and their associated risks.

Summary Table:

| Industry | Primary Hazards | Essential Safety Features |

|---|---|---|

| Construction & Heavy Industry | Falling objects, sharp debris | Steel/Composite Toe, Puncture-Resistant Sole |

| Manufacturing & Automotive | Slippery floors, chemicals | Slip-Resistant Outsole, Chemical Resistance |

| Oil & Gas | Slippery surfaces, harsh chemicals | Slip & Oil Resistance, Durability |

| Electrical Work | Live electrical circuits | Electrical Hazard (EH) Rating |

| Agriculture | Uneven terrain, chemicals | Slip Resistance, Chemical Resistance |

Need Reliable Work Shoes for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality, safety-compliant footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, precisely engineered to meet the specific demands of your industry.

We help you:

- Enhance workplace safety with footwear tailored to your unique hazards.

- Streamline procurement with reliable, large-volume manufacturing.

- Improve worker comfort and performance with durable, well-designed shoes.

Let's discuss your requirements and find the perfect safety solution for your workforce.

Contact our team today for a consultation

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- Why is professional-grade safety footwear essential for workers with peripheral neuropathy? Expert Protection Guide

- How do composite-toe boots benefit worker comfort and safety? Reduce Fatigue and Enhance Protection

- Why is it necessary to equip personnel with anti-slip safety shoes at rosin and turpentine production stations?

- What is the importance of safety footwear in various industries? Essential Protection for Your Workforce

- What materials are used for fasteners and laces in safety boots? | A Guide to Durability & Safety

- How should one choose between steel toe and composite toe shoes? Match Your Work Hazards for Optimal Safety

- Why is the maintenance of high-strength metal molds essential? Ensure Superior Safety Shoe Structural Integrity

- How does understanding safety shoe materials help in making informed choices? Match Your Work Hazards with the Right Protection