At their core, composite-toe boots offer workers safety protection equivalent to traditional steel toes but with significant advantages in comfort and specialized applications. They achieve this by using non-metallic materials like carbon fiber, fiberglass, or Kevlar, which reduces weight and eliminates electrical conductivity.

The primary benefit of composite-toe boots is that they deliver certified impact and compression protection without the inherent drawbacks of metal. This makes them a superior choice for workers who prioritize reduced daily fatigue, operate in extreme temperatures, or require non-conductive footwear.

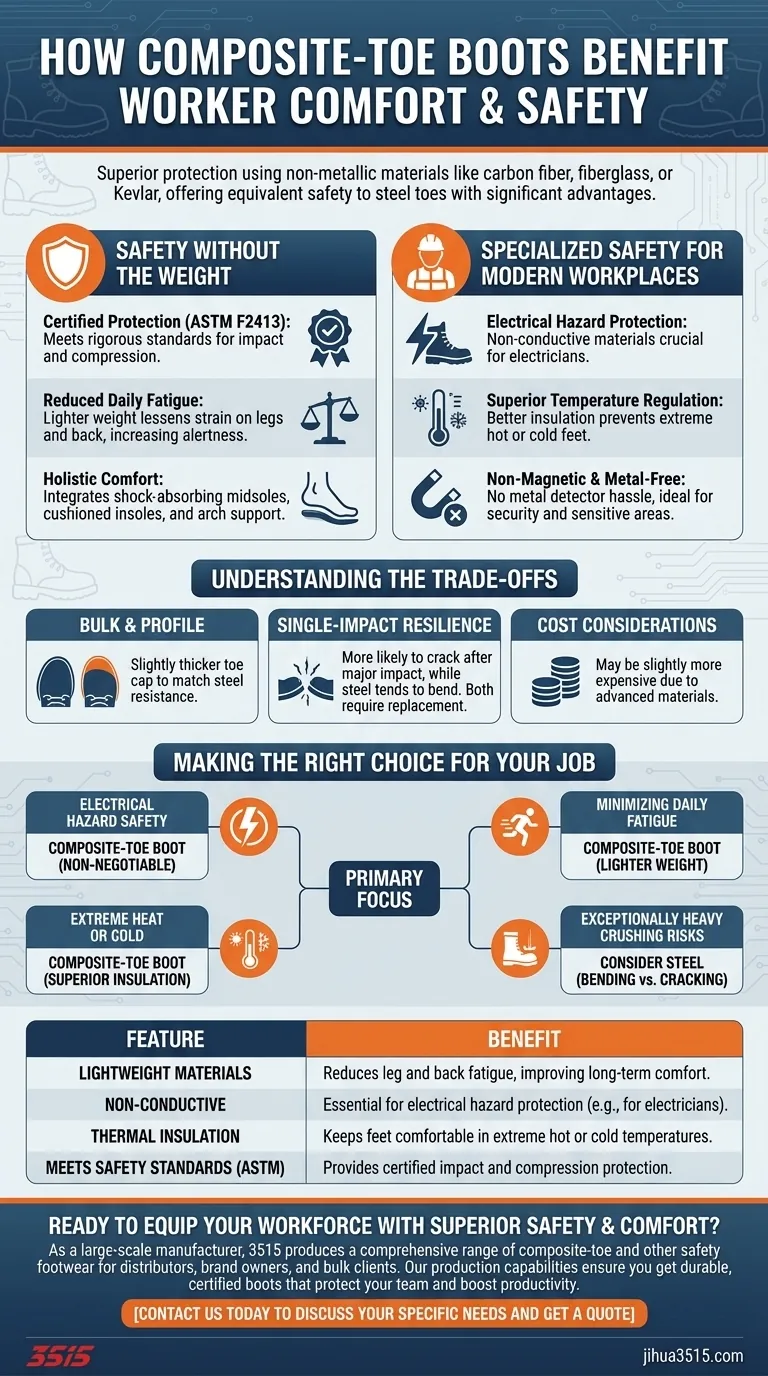

The Dual Advantage: Safety Without the Weight

The value proposition of composite-toe footwear is simple but powerful. It directly addresses the most common complaints about traditional safety boots—their weight and inflexibility—without compromising on the core mission of protecting your feet.

Meeting Rigorous Safety Standards

Composite-toe caps are engineered to meet or exceed the same industry safety standards (like ASTM F2413) as steel toes. They provide robust resistance to both impact and compression forces found in hazardous environments.

This ensures that workers in construction, manufacturing, or industrial settings receive the necessary protection against falling objects and heavy machinery.

The Critical Role of Lighter Materials

The most immediate benefit felt by the wearer is the significant reduction in weight. Lighter boots mean less strain on your feet, legs, and back over the course of a long workday.

This reduction in fatigue enhances overall job performance, increases alertness, and contributes to better long-term musculoskeletal health.

Beyond the Toe Cap: Holistic Comfort

Modern safety boots integrate comfort as a key feature. While the composite toe reduces weight, other elements like shock-absorbing midsoles, cushioned insoles, and built-in arch support work together.

These features alleviate the physical strain of standing for extended periods on hard surfaces, preventing common issues like sore spots and blisters.

Specialized Safety for Modern Workplaces

Beyond general protection, the non-metallic nature of composite materials provides unique safety advantages that are critical in certain professions.

Electrical Hazard Protection

Because materials like carbon fiber and fiberglass do not conduct electricity, composite-toe boots are an essential choice for electricians and anyone working near live circuits. This feature can be the difference between a minor incident and a serious injury.

Superior Temperature Regulation

Metal is an excellent conductor of temperature, meaning steel-toe boots can become uncomfortably cold in winter and hot in summer. Composite materials provide far better insulation, keeping the wearer's feet more comfortable in extreme weather conditions.

Non-Magnetic and Metal-Free

For workers who must pass through metal detectors frequently, such as those in security, logistics, or certain high-security industrial plants, composite-toe boots eliminate a daily hassle. Their non-magnetic properties are also vital in specific sensitive environments.

Understanding the Trade-offs

While composite-toe technology offers many advantages, an objective assessment requires acknowledging its trade-offs compared to traditional steel.

Bulk and Profile

To achieve the same level of impact resistance as steel, a composite toe cap often needs to be slightly thicker or bulkier. This can result in a more bulbous toe box, which may be a consideration for personal fit and preference.

Single-Impact Resilience

Both steel and composite toes are designed to protect you from a single, major impact, after which the footwear should be replaced. However, steel tends to bend under extreme force, while a composite toe is more likely to crack. Neither is reusable after a significant event.

Cost Considerations

The advanced materials and manufacturing processes involved can sometimes make composite-toe boots slightly more expensive than their steel-toe counterparts. This difference should be weighed as an investment in comfort, reduced fatigue, and specialized safety features.

Making the Right Choice for Your Job

Selecting the proper safety footwear is a strategic decision that directly impacts your daily performance and long-term health. Use your primary job function to guide your choice.

- If your primary focus is electrical hazard safety: A certified composite-toe boot is the non-negotiable choice.

- If your primary focus is minimizing daily fatigue: The lighter weight of composite-toe boots offers a clear advantage for anyone who walks or stands all day.

- If your primary focus is working in extreme heat or cold: Composite toes provide superior thermal insulation and will keep your feet more comfortable than steel.

- If your primary focus is working around exceptionally heavy crushing risks: While both are certified, some professionals prefer the tendency of steel to bend rather than shatter under loads that exceed safety ratings.

Ultimately, choosing the right boot is an investment in your ability to perform your job safely and effectively, day after day.

Summary Table:

| Feature | Benefit |

|---|---|

| Lightweight Materials | Reduces leg and back fatigue, improving long-term comfort. |

| Non-Conductive | Essential for electrical hazard protection (e.g., for electricians). |

| Thermal Insulation | Keeps feet comfortable in extreme hot or cold temperatures. |

| Meets Safety Standards (ASTM) | Provides certified impact and compression protection. |

Ready to equip your workforce with superior safety and comfort?

As a large-scale manufacturer, 3515 produces a comprehensive range of composite-toe and other safety footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure you get durable, certified boots that protect your team and boost productivity.

Contact us today to discuss your specific needs and get a quote!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene