Understanding the materials in a safety shoe is the single most important factor in making an informed choice. It allows you to move beyond brand names and marketing to evaluate a shoe based on its core components, ensuring you can precisely match its protective features, durability, and comfort to your specific workplace hazards and daily tasks. This knowledge transforms your choice from a guess into a calculated decision for your safety and well-being.

The material composition of a safety shoe isn't just a feature—it's the foundation of its performance. Choosing the right materials directly impacts your safety, your comfort, and the footwear's lifespan, preventing the costly and painful mistake of using the wrong tool for the job.

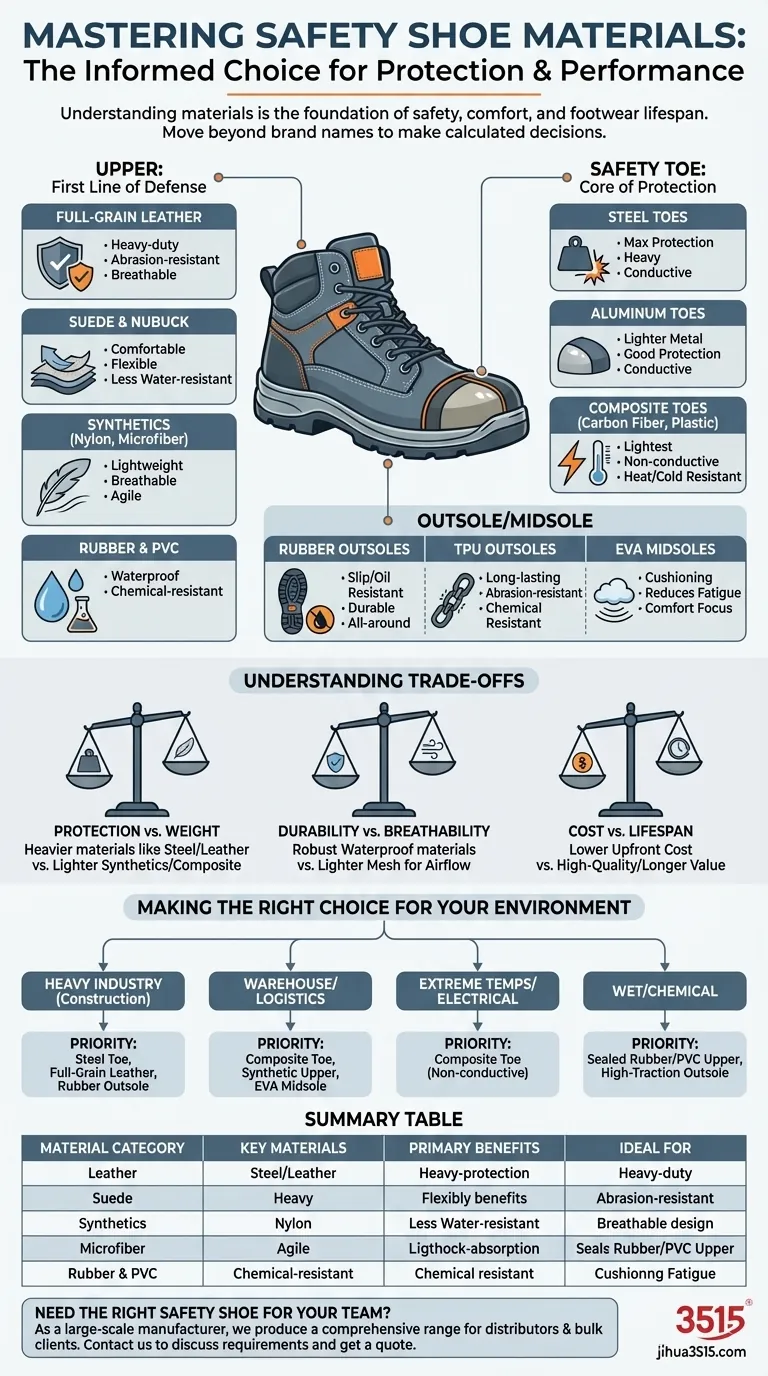

Deconstructing the Upper: The First Line of Defense

The "upper" is everything above the sole. Its material dictates the shoe's breathability, durability, flexibility, and resistance to environmental factors like water and chemicals.

Full-Grain Leather

This is the classic material for heavy-duty work boots. It offers superior durability, abrasion resistance, and breathability compared to other leather types. It molds to your foot over time but requires a break-in period.

Suede & Nubuck Leather

These are softer, more flexible leathers that provide excellent comfort. However, they are less resistant to water and stains, making them better suited for dry, indoor environments.

Synthetic Materials (Nylon, Polyester, Microfiber)

Synthetics offer a lightweight, often more breathable, and typically more affordable alternative to leather. They are excellent for light industrial work, logistics, and indoor roles where agility is key.

Rubber & PVC

These materials provide complete waterproofing and high resistance to chemicals. They are non-negotiable for work in extremely wet conditions or environments with chemical splash hazards.

The Core of Protection: Safety Toe Materials

The safety toe cap is the critical component for impact protection. The material used has a significant effect on the shoe's weight, comfort, and suitability for certain environments.

Steel Toes: The Traditional Standard

Steel offers the maximum level of protection against impact and compression and can be made with a low-profile cap. Its main drawbacks are its weight and its conductivity of heat and cold.

Aluminum Toes: The Lighter Metal

Offering similar protection to steel, aluminum toes are significantly lighter, reducing foot fatigue. They are still conductive and are often thicker than their steel counterparts.

Composite Toes: The Modern Alternative

Made from non-metal materials like carbon fiber, plastic, or Kevlar, composite toes are the lightest option. They do not conduct heat, cold, or electricity, making them essential for electricians or workers in extreme temperatures.

The Foundation: Outsole Materials and Their Purpose

The outsole is what contacts the ground. Its material determines grip, durability, and resistance to hazards like oil, chemicals, and heat.

Rubber Outsoles

Rubber is the all-around workhorse, providing excellent resistance to slips, oil, and abrasions. It is a durable and reliable choice for most general and heavy-duty work environments.

TPU (Thermoplastic Polyurethane) Outsoles

TPU is a modern material known for being exceptionally tough and long-lasting. It is highly resistant to splitting, abrasion, oil, and chemicals, often outperforming rubber in durability.

EVA (Ethylene Vinyl Acetate) Midsoles

While not an outsole, the EVA midsole is a critical comfort component. This foam material provides cushioning and shock absorption, significantly reducing fatigue. It is common in athletic-style safety shoes.

Understanding the Trade-offs

No single material is perfect for every situation. Making an informed choice means balancing competing factors to find the right shoe for your specific needs.

Protection vs. Weight

Heavier materials like steel and full-grain leather often provide the highest levels of durability and impact resistance. Lighter synthetic and composite options reduce fatigue but may offer less resistance to abrasion.

Durability vs. Breathability

Robust, waterproof materials like rubber or treated leather offer maximum protection from the elements but can trap heat and sweat. Lighter synthetic mesh provides superior airflow but is less durable and offers minimal water resistance.

Cost vs. Lifespan

Lower-cost materials can make a shoe more affordable upfront. However, a boot made from high-quality components like full-grain leather and a TPU outsole will almost always last longer, providing better value over its lifetime.

Making the Right Choice for Your Work Environment

Use your understanding of materials to select footwear that is purpose-built for your job's demands.

- If your primary focus is maximum impact protection in heavy industry (construction, manufacturing): Prioritize steel toes and durable full-grain leather uppers with a slip-resistant rubber outsole.

- If your primary focus is all-day comfort and mobility in a warehouse or logistics role: Look for a lightweight composite toe shoe with synthetic uppers and an EVA midsole for cushioning.

- If your primary focus is working in extreme temperatures or around electrical hazards: A composite toe is non-negotiable, as it does not conduct heat, cold, or electricity.

- If your primary focus is dealing with wet conditions or chemicals: Choose a boot with a sealed rubber or PVC upper and a high-traction outsole designed for slick surfaces.

By understanding these core materials, you can select safety footwear that works for you, not against you, ensuring both protection and productivity.

Summary Table:

| Material Category | Key Materials | Primary Benefits | Ideal For |

|---|---|---|---|

| Upper | Full-Grain Leather, Suede, Synthetic, Rubber/PVC | Durability, Breathability, Waterproofing | Heavy-duty, Wet conditions, Light industrial work |

| Safety Toe | Steel, Aluminum, Composite | Impact Protection, Lightweight, Non-conductive | Construction, Warehouses, Electrical work |

| Outsole | Rubber, TPU, EVA (Midsole) | Slip Resistance, Durability, Cushioning | General work, Oily surfaces, All-day comfort |

Need the Right Safety Shoe for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, ensuring you get durable, comfortable, and purpose-built footwear that meets your specific workplace safety standards.

Contact us today to discuss your requirements and get a quote for high-quality, reliable safety footwear.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Sport Style Safety Boots for Bulk Orders

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What do heavy duty boots do? Protect Your Feet in Demanding Work Environments

- Is safety-toe as good as steel toe? Choose the Right Protection for Your Job

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management