-

Deconstructing the Request: I'm acting as a trusted advisor, aiming for clarity and actionable insights. The surface question is about materials, but the real need is to understand the implications of those materials for safety and performance.

-

Analyzing the References: I'll focus on the core information: metal fasteners (brass, stainless steel) for durability and synthetic laces (nylon, polyester) for strength and flexibility. I'll discard irrelevant references about the boot's body.

-

Synthesizing and Structuring: I'll begin by directly answering the question: safety boots use metal fasteners (brass, stainless steel) and synthetic laces (nylon, polyester). My Core Takeaway will highlight the deliberate engineering balancing strength, environmental resistance, and user safety. The guide will then explain why these materials are used: metal for corrosion resistance and strength, and synthetics for high tensile strength, abrasion resistance, and water repellency.

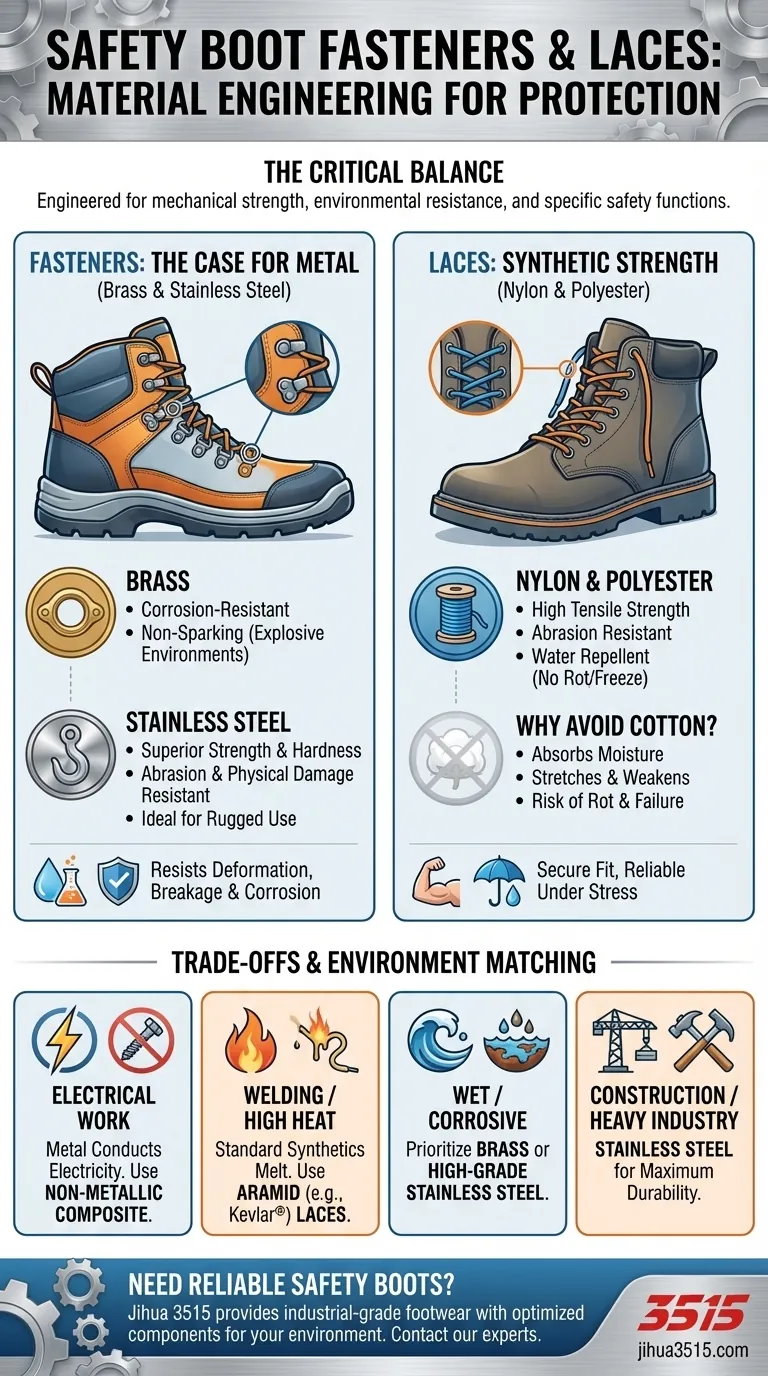

I'll include a crucial Trade-offs section. For instance, metal fasteners can conduct electricity, a critical point for electricians. I'll also explain that, while strong, synthetic laces aren't indestructible and might wear out in specific conditions. Finally, I'll provide actionable advice with targeted bullet points for different work environments (construction, electrical, wet). I'll conclude with an empowering statement, emphasizing that understanding these material choices leads to smarter choices in safety footwear. In safety footwear, every component is engineered for a specific function. The fasteners, such as eyelets and hooks, are almost always made from durable metals like brass or stainless steel. The laces, in contrast, are made from high-strength synthetic fibers, typically nylon or polyester, to provide a secure fit without failing under stress.

The material choices for safety boot fasteners and laces are not arbitrary. They represent a critical balance between mechanical strength, resistance to environmental decay, and specific occupational safety requirements like non-conductivity.

Why Material Choice Matters for Fasteners

The small metal components that hold your laces are critical points of failure. Their material composition is designed to ensure the boot remains securely on your foot throughout the most demanding conditions.

The Case for Metal: Durability and Resistance

Fasteners must withstand constant tension and abrasion. Metals like brass and stainless steel are chosen because they resist deformation and breakage far better than plastics or other materials.

Furthermore, they are highly resistant to corrosion. This ensures that exposure to water, mud, or chemicals on a worksite won't cause them to rust and weaken over time.

Brass vs. Stainless Steel

Brass is an alloy of copper and zinc, making it naturally corrosion-resistant and non-sparking. This non-sparking property can be a critical safety feature in potentially explosive environments.

Stainless steel offers superior strength and hardness, making it exceptionally resistant to physical damage and abrasion. It is the go-to choice for the most rugged and demanding work boots.

The Engineering Behind Safety Boot Laces

A boot lace is not just a string; it's a tension-bearing component that must be reliable. The choice of synthetic fibers is a deliberate decision based on performance under stress.

The Strength of Synthetics: Nylon and Polyester

Nylon and polyester are the standard for high-quality work boot laces due to their exceptional tensile strength, meaning they can withstand significant pulling force before breaking.

These synthetic materials also resist abrasion well and do not absorb water. This prevents them from stretching when wet, freezing in cold weather, or becoming susceptible to rot and mildew.

Why Natural Fibers Are Avoided

Laces made from natural fibers like cotton are unsuitable for safety footwear. Cotton readily absorbs moisture, causing it to stretch, weaken, and eventually rot. A failed lace can create a serious trip hazard or cause the boot to come off at a critical moment.

Understanding the Trade-offs and Pitfalls

While these materials are chosen for their strengths, it's important to be aware of their inherent limitations to make the safest choice for your specific job.

Metal Fastener Conductivity

A key consideration for electricians or anyone working near live circuits is that metal fasteners conduct electricity. For these roles, boots with non-metallic, composite eyelets and hooks are essential to minimize the risk of electrical shock.

Lace Durability Under Extreme Heat

While robust, standard nylon or polyester laces can melt or be severed by high heat sources like welding sparks or hot metal slag. Specialized, heat-resistant laces (often made with Aramid fibers like Kevlar®) are required for such applications.

The Myth of "Unbreakable" Laces

No lace is truly indestructible. They are a wear item that should be inspected regularly for fraying or abrasion, especially around the eyelets. Replacing worn laces is a simple but critical part of maintaining your footwear's safety.

Matching Materials to Your Work Environment

Use this guide to select the right components for your specific needs.

- If your primary focus is general construction or heavy industry: Prioritize boots with stainless steel fasteners for maximum durability against physical abuse.

- If your primary focus is electrical work: Seek out boots that explicitly feature non-metallic, composite fasteners and eyelets to eliminate conductivity risk.

- If your primary focus is welding or high-heat environments: Ensure your boots are equipped with specialized, flame-resistant laces made from Aramid fibers.

- If your primary focus is wet or corrosive environments: Look for brass or high-grade stainless steel fasteners that offer superior protection against rust and degradation.

Understanding these material choices empowers you to select safety footwear that is not just compliant, but truly optimized for your protection.

Summary Table:

| Component | Common Materials | Key Benefits |

|---|---|---|

| Fasteners | Brass, Stainless Steel | Corrosion resistance, high strength, durability |

| Laces | Nylon, Polyester | High tensile strength, abrasion resistance, water repellency |

Need reliable safety boots built with the right materials?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure every component—from durable metal fasteners to high-strength synthetic laces—is engineered for optimal performance and safety in your specific work environment.

Contact our experts today to discuss your safety boot requirements and benefit from our industrial-grade manufacturing solutions.

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What is the overall recommendation regarding steel toe boot usage? Essential for Maximum Protection

- What are steel toe boots and how are they designed? Essential Guide to Industrial Footwear Safety

- What safety features can some gumboots have? Essential PPE for Hazardous Work Environments

- Is it true that steel toe boots make your toes colder? The Truth About Cold-Weather Work Boots

- In what work situations might cowboy boots not be appropriate? A Guide to Safety & Dress Code Compliance