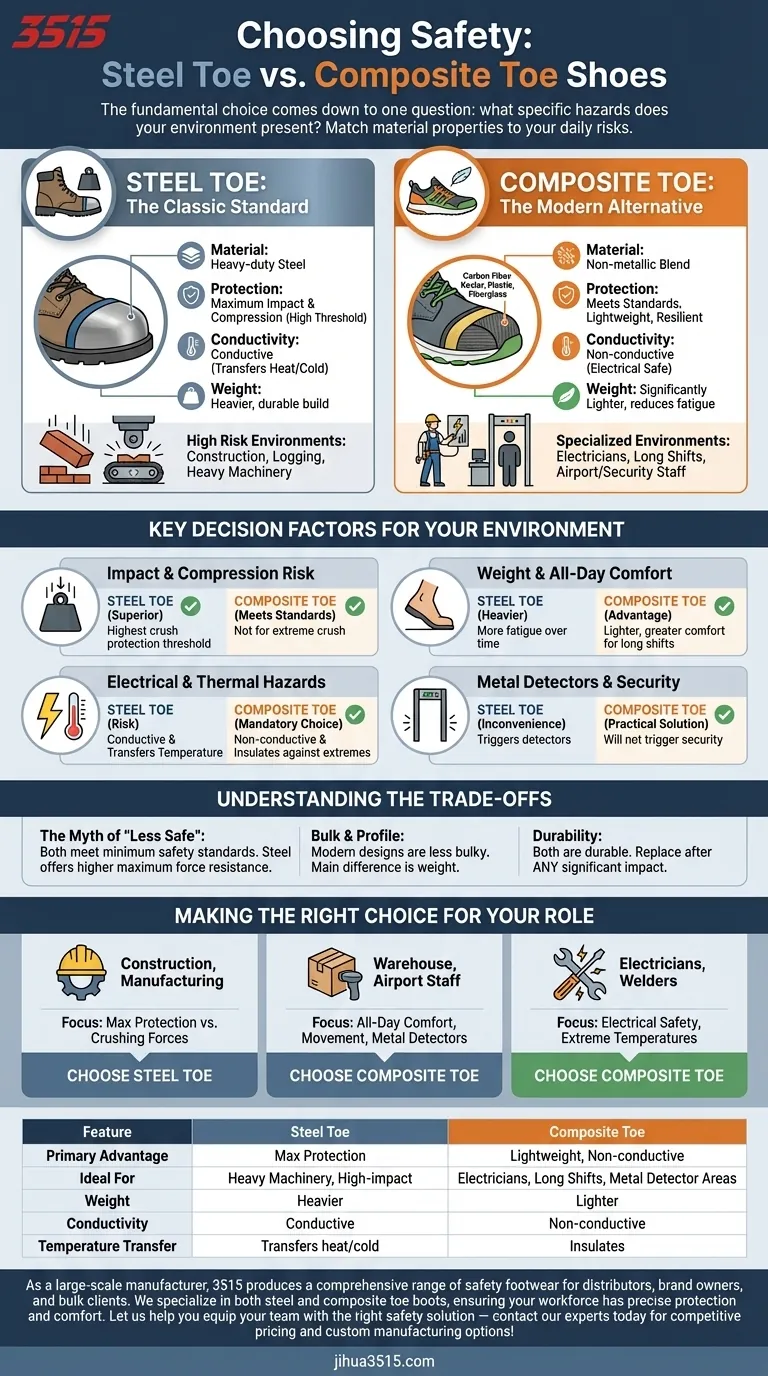

The fundamental choice between steel and composite toe shoes comes down to a single question: what specific hazards does your environment present? Steel toes offer the absolute highest level of protection against impact and compression, making them the standard for high-risk jobs. Composite toes, made from non-metallic materials like Kevlar or carbon fiber, provide a modern alternative that excels in comfort, lightweight performance, and protection against electrical or thermal hazards.

The decision is not about which toe cap is universally "better," but about correctly matching the material's inherent properties—maximum strength vs. lightweight versatility—to the specific risks and demands of your daily work.

The Core Difference: Material and Design

Understanding what each safety toe is made of is the first step. The material dictates every other performance characteristic, from weight to conductivity.

Steel Toe: The Classic Standard

A steel toe cap is exactly what it sounds like: a reinforcement made of heavy-duty steel. It is built to withstand extreme forces.

This design provides the maximum possible protection against both direct impacts (falling objects) and compression (crushing forces).

Composite Toe: The Modern Alternative

Composite toes are crafted from a blend of non-metallic materials, including carbon fiber, plastic, fiberglass, or Kevlar.

This construction makes them significantly lighter than steel and completely non-conductive, which is a critical feature for certain specialized environments.

Key Decision Factors for Your Environment

Your choice should be a calculated decision based on the primary challenges of your role. Evaluate these factors to determine the optimal fit.

Level of Impact and Compression Risk

For environments with a high risk of severe impact, such as construction sites, logging operations, or anywhere heavy machinery is used, steel toe is the superior choice. It offers a higher threshold for protection against crushing force.

While composite toes meet all required safety standards (like those from ASTM), they do not offer the same ultimate level of crush protection as steel.

Weight and All-Day Comfort

If your job involves extensive walking, climbing, or long shifts on your feet, composite toe shoes offer a distinct advantage.

Their lighter weight reduces foot fatigue over the course of a day, leading to greater comfort and potentially higher productivity.

Electrical and Thermal Hazards

This is where composite toes have a clear technical advantage. Because they contain no metal, they are non-conductive.

This makes composite toe footwear the mandatory choice for electricians or workers who face electrical hazards. The non-metallic nature also means they don't transfer cold or heat, making them far more comfortable in extreme temperature environments.

Metal Detectors and Security

For workers who must frequently pass through metal detectors, such as airport personnel, security guards, or employees at high-security facilities, composite toe shoes are the practical solution.

They will not trigger security screening devices, eliminating a significant daily inconvenience.

Understanding the Trade-offs

Neither option is perfect; each comes with inherent compromises. Being aware of these limitations is key to making an informed decision.

The Myth of "Less Safe"

A common misconception is that composite toes are unsafe. This is incorrect. Both types must meet the same minimum safety standards for impact and compression resistance set by regulatory bodies.

The difference lies in their maximum capability. Steel can withstand a higher level of force before failing, making it necessary for the most extreme-risk environments.

Bulk and Overall Profile

Historically, steel toe caps were bulkier than their composite counterparts. However, modern manufacturing has narrowed this gap significantly.

While composite designs can sometimes offer a slightly sleeker profile, the primary difference you will feel is in weight, not overall size.

Durability and Lifespan

Both steel and composite toe boots are built for durability. The steel cap itself is exceptionally resilient to damage.

A key point is that after any significant impact event, a safety boot—regardless of toe type—should be replaced, as its protective structure may be compromised.

Making the Right Choice for Your Role

Filter your decision through the lens of your primary daily objective.

- If your primary focus is maximum protection against heavy objects or crushing forces (e.g., construction, manufacturing): Choose steel toe for its unparalleled impact resistance.

- If your primary focus is all-day comfort, constant movement, or passing through metal detectors (e.g., warehouse logistics, airport staff): Choose composite toe for its lightweight and non-metallic properties.

- If your primary focus is safety from electrical hazards or working in extreme temperatures (e.g., electricians, welders): Choose composite toe for its critical non-conductive features.

By aligning your footwear's material properties with your daily risks, you ensure both regulatory compliance and functional comfort on the job.

Summary Table:

| Feature | Steel Toe | Composite Toe |

|---|---|---|

| Primary Advantage | Maximum impact/compression protection | Lightweight, non-conductive |

| Ideal For | Heavy machinery, construction, high-impact risks | Electricians, long shifts, metal detector areas |

| Weight | Heavier | Lighter |

| Conductivity | Conductive (not for electrical work) | Non-conductive (electrically safe) |

| Temperature Transfer | Transfers heat/cold | Insulates against temperature extremes |

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. We specialize in both steel toe and composite toe boots, ensuring your workforce has the precise protection and comfort they need. Our production capabilities encompass all types of shoes and boots, tailored to your specific industry hazards. Let us help you equip your team with the right safety solution — contact our experts today for competitive pricing and custom manufacturing options!

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What specific safety functions do high-performance safety shoes provide for workers? Protect Your Team on-Site

- What is the significance of the new ASTM standard for slip resistant safety footwear? A Clear Benchmark for Safety

- What role do safety shoes play within HIRADC in open-pit mining? The Ultimate Guide to Final-Line Risk Control

- Are safety shoes good for walking? Why Purpose-Built Footwear Matters for Comfort and Health

- What role do wearable IMUs play in optimizing protective equipment? Data-Driven Safety for Heavy Labor

- Which is better, steel toe or composite toe boots? Match Your Job's Hazards for Optimal Safety

- How can material engineering and ergonomic design address PPE heat and pressure? Advanced Comfort for Long-Term Safety

- What role does the Content Localization strategy play in the overseas promotion of safety shoes? Drive Global Growth