The choice between steel-toe and soft-toe boots is a critical decision that directly impacts your daily safety and comfort at work. The correct answer depends entirely on a clear-eyed assessment of your job site's specific hazards, any mandatory safety standards you must meet, and the physical demands of your role. While steel-toe boots offer essential protection against impact, soft-toe boots provide superior comfort in lower-risk settings.

Your decision is not about which boot is inherently "better," but which is explicitly appropriate for the risks you face. Steel-toe boots are the non-negotiable standard for protection against impact and compression, while soft-toe boots offer the comfort and flexibility needed for physically demanding jobs in non-hazardous environments.

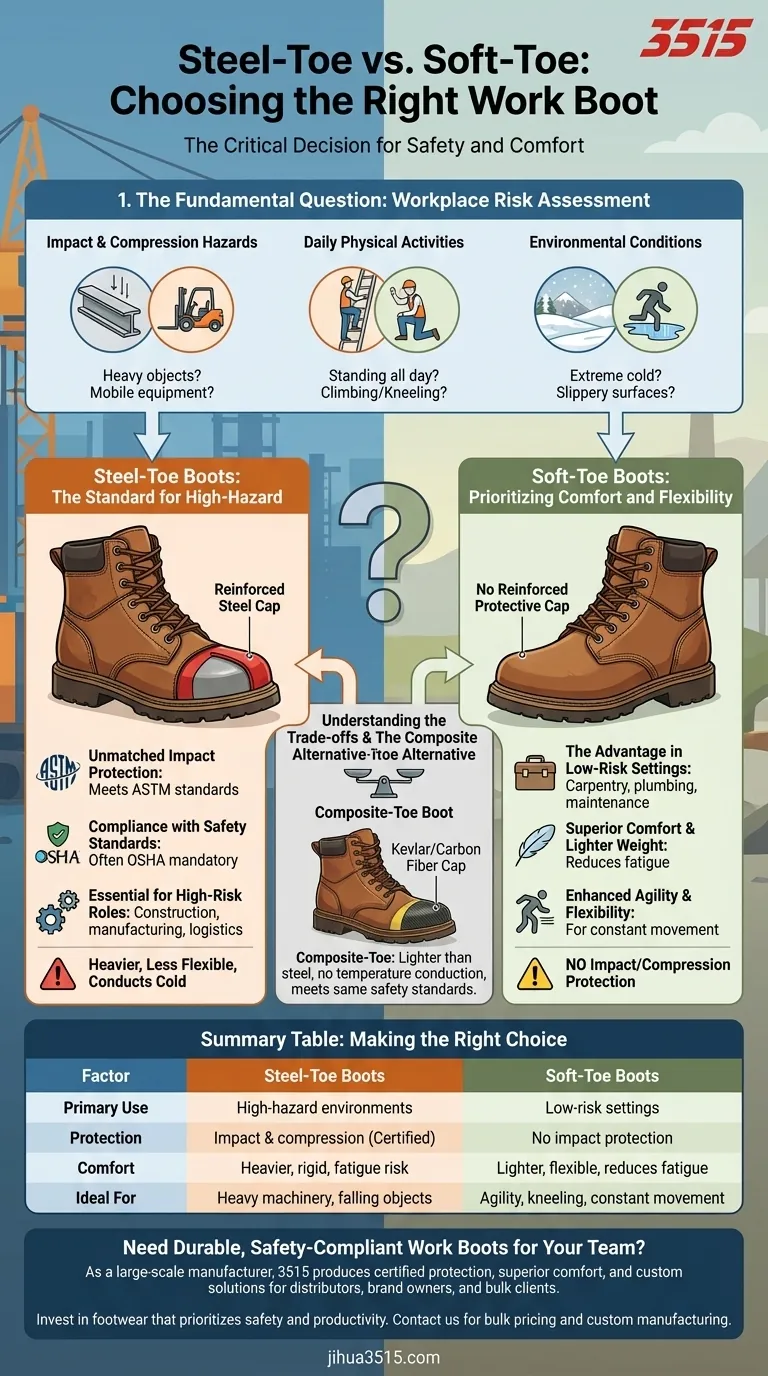

The Fundamental Question: What Are Your Workplace Risks?

Before you can choose a boot, you must first perform a simple risk assessment of your typical workday. This analysis is the foundation for making a responsible and safe decision.

Assessing Impact and Compression Hazards

The primary reason for safety-toe boots is to protect your feet from crush injuries. Ask yourself: Do I work around heavy materials, mobile equipment like forklifts, or have a risk of heavy objects falling onto my feet? If the answer is yes, a protective toe is required.

Evaluating Your Daily Physical Activities

Consider the physical nature of your job. Do you spend hours standing on hard concrete? Are you constantly climbing ladders, kneeling, or walking long distances? These activities place a premium on boot weight, flexibility, and overall comfort.

Understanding Environmental Conditions

Think about your surroundings. Do you work on uneven terrain, slippery surfaces, or in extreme temperatures? Steel can conduct cold in winter, while certain materials offer better traction or waterproofing, which are factors that exist independent of the toe type.

Steel-Toe Boots: The Standard for High-Hazard Environments

A steel-toe boot contains a reinforced steel cap over the toe area. Its purpose is singular and critical: to prevent injury from falling objects and compression.

Unmatched Impact Protection

The core function of a steel toe is to meet specific safety standards for impact and compression resistance, typically set by organizations like the ASTM (American Society for Testing and Materials). This is your frontline defense against serious workplace accidents.

Compliance with Safety Standards

Many job sites, particularly in construction, manufacturing, and logistics, are governed by OSHA (Occupational Safety and Health Administration) regulations. These rules often mandate the use of certified protective footwear, making steel-toe boots a condition of employment.

Essential for High-Risk Roles

If your job involves operating heavy machinery, working in a warehouse with rolling equipment, or handling heavy parts and materials, the protection offered by a steel toe is not a feature—it is a necessity.

Soft-Toe Boots: Prioritizing Comfort and Flexibility

Soft-toe boots have no reinforced protective cap. They are designed for roles where the risk of a foot-crushing injury is negligible, allowing designers to focus on other features.

The Advantage in Low-Risk Settings

In professions like carpentry, plumbing, or general maintenance where the primary hazards are slips or punctures rather than falling objects, a soft-toe boot is often sufficient. They provide ankle support and traction without the added bulk of a safety toe.

Superior Comfort and Lighter Weight

The most significant benefit of a soft-toe boot is its reduced weight. Removing the steel cap makes the boot lighter and more flexible, which dramatically reduces foot fatigue over a long and active day.

Enhanced Agility and Flexibility

Without a rigid toe cap, a soft-toe boot allows for more natural foot movement. This is a major advantage for workers who need to frequently squat, kneel, or work in awkward positions.

Understanding the Trade-offs

Choosing the right boot means accepting a specific set of compromises. Being aware of these trade-offs is key to making an informed decision.

The Weight and Comfort Penalty of Steel-Toes

The primary drawback of steel-toe boots is their weight and rigidity. This can lead to greater fatigue and less comfort, especially for workers who are constantly on the move. They can also be colder in winter environments as the steel conducts temperature.

The Protection Gap of Soft-Toes

The critical trade-off for a soft-toe boot is the complete absence of impact and compression protection. Choosing this option in an environment with even a small risk of falling objects is a serious safety gamble.

The "Composite-Toe" Alternative

It's important to know about composite-toe boots, which use non-metallic materials like Kevlar, carbon fiber, or plastic for protection. They meet the same safety standards as steel but are lighter and do not conduct electricity or temperature, offering a modern middle ground.

Making the Right Choice for Your Job

Your final decision should be guided by a clear understanding of your primary daily need: absolute safety or functional comfort.

- If your primary focus is compliance and protection from heavy objects: A certified steel-toe or composite-toe boot is your only safe and acceptable option.

- If your primary focus is all-day comfort in a certifiably low-risk environment: A soft-toe boot will reduce fatigue and provide greater flexibility for constant movement.

- If your primary focus is a balance of certified protection and lighter weight: Consider a composite-toe boot, which meets safety standards without the weight and temperature conductivity of steel.

Ultimately, choosing the right work boot is a direct investment in your personal safety and long-term well-being on the job.

Summary Table:

| Factor | Steel-Toe Boots | Soft-Toe Boots |

|---|---|---|

| Primary Use | High-hazard environments (construction, manufacturing) | Low-risk settings (carpentry, plumbing) |

| Protection | Impact and compression resistance (ASTM/OSHA certified) | No impact protection; focuses on slip/puncture resistance |

| Comfort | Heavier and more rigid; may cause fatigue | Lighter, flexible, and reduces foot fatigue |

| Ideal For | Jobs with heavy machinery, falling objects, or rolling equipment | Roles requiring agility, kneeling, or constant movement |

Need Durable, Safety-Compliant Work Boots for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of steel-toe, composite-toe, and soft-toe boots for distributors, brand owners, and bulk clients. Whether you need OSHA-compliant safety footwear for high-risk industries or lightweight options for agile workforces, we deliver:

- Certified Protection: Meets ASTM/OSHA standards for impact and compression resistance.

- Superior Comfort: Engineered for all-day wear with reduced fatigue.

- Custom Solutions: Tailored designs for your specific industry needs.

Invest in footwear that prioritizes safety and productivity. Contact us today for bulk pricing, catalog requests, or custom manufacturing quotes!

Visual Guide

Related Products

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Mesh Steel Toe Safety Shoes with Dial Closure Factory Production

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- Which professions commonly use safety work boots? A Guide to Industry-Specific Footwear

- What are the requirements for a protective toe cap? Meet ASTM F2413 Standards for Maximum Safety

- How can you optimize the fit of steel toe boots for better comfort? A Complete Guide to Custom Fit

- What types of safety toe boots are available? Find the Perfect Fit for Your Job's Hazards

- What tips can help ensure safety toe boots fit correctly? Achieve Optimal Protection & Comfort