To optimize the fit of your steel toe boots, you must go beyond simply wearing them. The most effective approach combines a gradual break-in period with targeted adjustments like using high-quality insoles, employing specific lacing techniques to relieve pressure points, and using boot stretchers or conditioners for stubborn areas.

True comfort in a steel toe boot is not found off the shelf; it is achieved through a systematic process of personalizing the boot's interior and structure to match the unique shape of your foot.

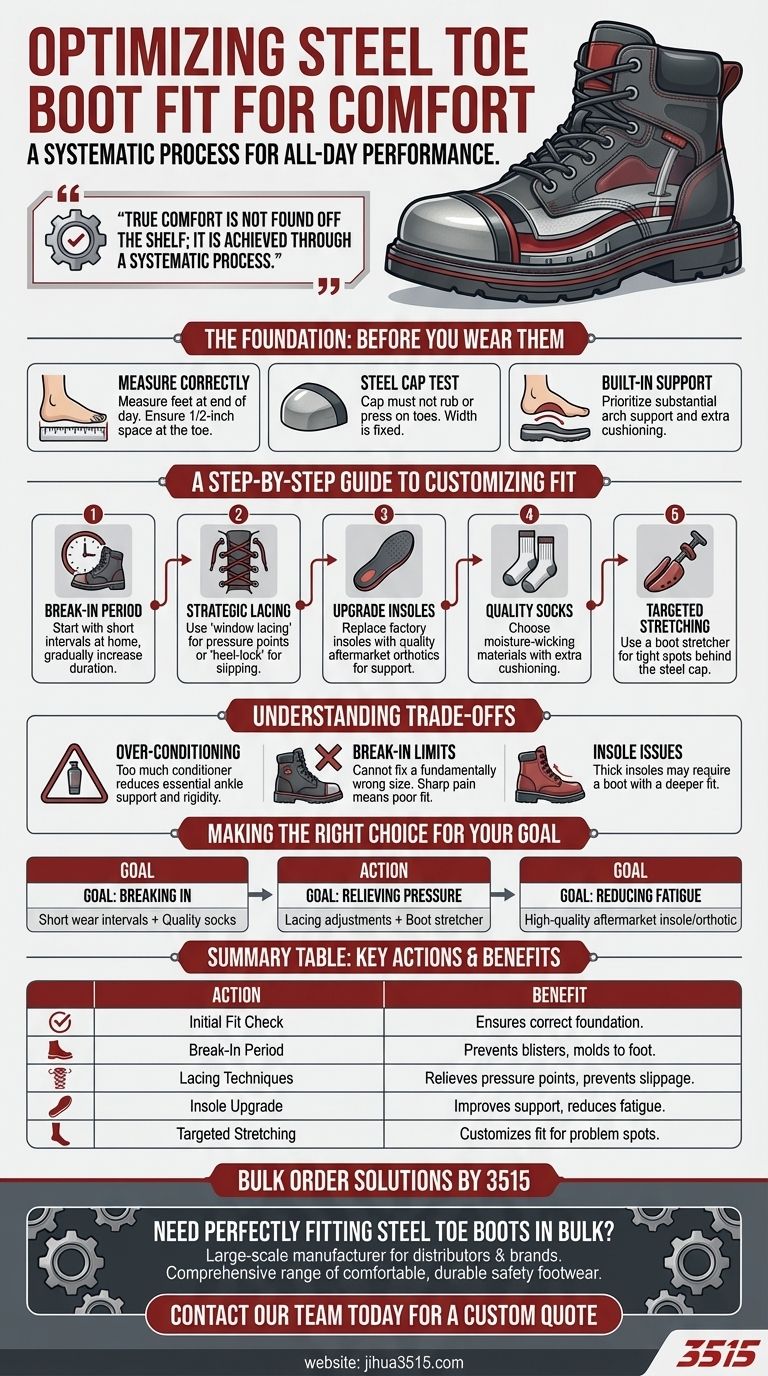

The Foundation: It Begins Before You Wear Them

Lasting comfort is impossible if the boot is fundamentally wrong for your foot. Before attempting any adjustments, ensure you have the right starting point.

Correct Foot Measurement is Non-Negotiable

Your foot size can change over time. Always measure your feet at the end of the day, as they tend to swell slightly. Ensure there is about a half-inch of space between your longest toe and the end of the boot.

The Steel Cap Test

When trying on boots, the steel toe cap should not press or rub against your toes while you stand or walk. The width of the safety cap is a fixed dimension and cannot be stretched, making this a critical initial fit point.

Prioritize Built-in Support

Look for boots designed with comfort in mind from the start. Key features include substantial arch support and extra cushioning in the midsole, which absorb shock and reduce fatigue.

A Step-by-Step Guide to Customizing Fit

Once you have a well-chosen boot, you can begin the process of molding it to your foot for optimal performance and comfort.

The Break-In Period: A Crucial First Step

Never wear a brand-new pair of boots for a full workday. Start by wearing them for just a few hours at a time at home, gradually increasing the duration over several days. This allows the leather and internal components to slowly conform to your foot's shape without causing blisters.

Strategic Lacing for Pressure Relief

Your lacing can be a powerful tool for fit adjustment. If you feel pressure on the top of your foot, try a "window lacing" technique, where you skip a set of eyelets to create a gap over the sensitive area. A "heel-lock" lacing technique can prevent your heel from slipping, which is a common cause of blisters.

Upgrading Your Insoles

The factory insoles that come with most boots offer minimal support. Investing in high-quality aftermarket insoles or orthotics is one of the most significant upgrades you can make. They provide superior arch support, cushioning, and can correct minor alignment issues.

The Unsung Hero: Quality Socks

The right socks are essential. Choose moisture-wicking materials like wool or specific synthetics to keep your feet dry and prevent blisters. A sock with extra cushioning in the heel and ball of the foot can also dramatically improve comfort.

Stretching for Problem Areas

For specific tight spots, especially in leather boots, a boot stretcher can be used to target and expand the material. This is particularly effective for widening the area just behind the steel toe cap.

Understanding the Trade-offs

Optimizing fit requires balance. Pushing an adjustment too far can compromise the boot's protective qualities.

The Danger of Over-Conditioning

Leather conditioner is excellent for softening stiff leather and making it more pliable. However, over-conditioning can make the leather too soft, reducing the critical ankle support and rigidity required for a safety boot.

The Limits of Breaking In

A break-in period can make a good-fitting boot feel great, but it cannot fix a boot that is fundamentally the wrong size or shape for your foot. If you feel sharp, pinching pain, the boot is likely too small or narrow.

When Insoles Mask a Deeper Problem

While insoles can solve many comfort issues, they can also take up extra volume inside the boot. If adding an insole makes the boot feel too tight across the top of your foot, you may need a boot with a deeper fit to begin with.

Making the Right Choice for Your Goal

Use these guidelines to focus your efforts based on the specific issue you're facing.

- If your primary focus is breaking in new boots: Wear them for short, increasing intervals and pair them with high-quality, moisture-wicking socks.

- If your primary focus is relieving specific pressure points: Adjust your lacing techniques to bypass sensitive areas and consider a boot stretcher for tight spots.

- If your primary focus is reducing all-day foot fatigue: Invest in a high-quality aftermarket insole or orthotic that provides proper arch support.

Ultimately, treating your boot as a customizable piece of essential equipment is the key to all-day comfort and safety.

Summary Table:

| Optimization Step | Key Action | Primary Benefit |

|---|---|---|

| Initial Fit Check | Measure feet, test steel cap fit | Ensures correct foundation |

| Break-In Period | Wear for short, increasing intervals | Prevents blisters, molds boot to foot |

| Lacing Techniques | Use window lacing or heel-lock methods | Relieves pressure points, prevents slippage |

| Insole Upgrade | Install high-quality aftermarket insoles | Improves arch support and reduces fatigue |

| Targeted Stretching | Use a boot stretcher on tight areas | Customizes fit for specific problem spots |

Need perfectly fitting steel toe boots in bulk? As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, designed with comfort and durability in mind. Let us help you equip your workforce with reliable, comfortable footwear. Contact our team today to discuss your bulk order needs and receive a custom quote.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Sport Style Safety Boots for Bulk Orders

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What's the difference between steel toe and safety-toe boots? Choose the Right Protection for Your Job

- Are steel or composite toe boots OSHA approved? Decoding the Standards for Workplace Safety

- What is the article's conclusion about choosing between steel and composite toe caps? Match Your Job to the Right Safety.

- What are the key properties of steel that make it suitable for toe caps? Maximum Protection & Durability

- How does composite toe compare to steel toe? Choose the Right Safety for Your Job

- What are the main reasons steel toe boots cause discomfort? Unlock All-Day Comfort & Safety

- In which work environments are steel toe shoes particularly necessary? Essential for Construction, Warehousing & More

- What are the most common types of safety toe caps? Choose the Right Protection for Your Job