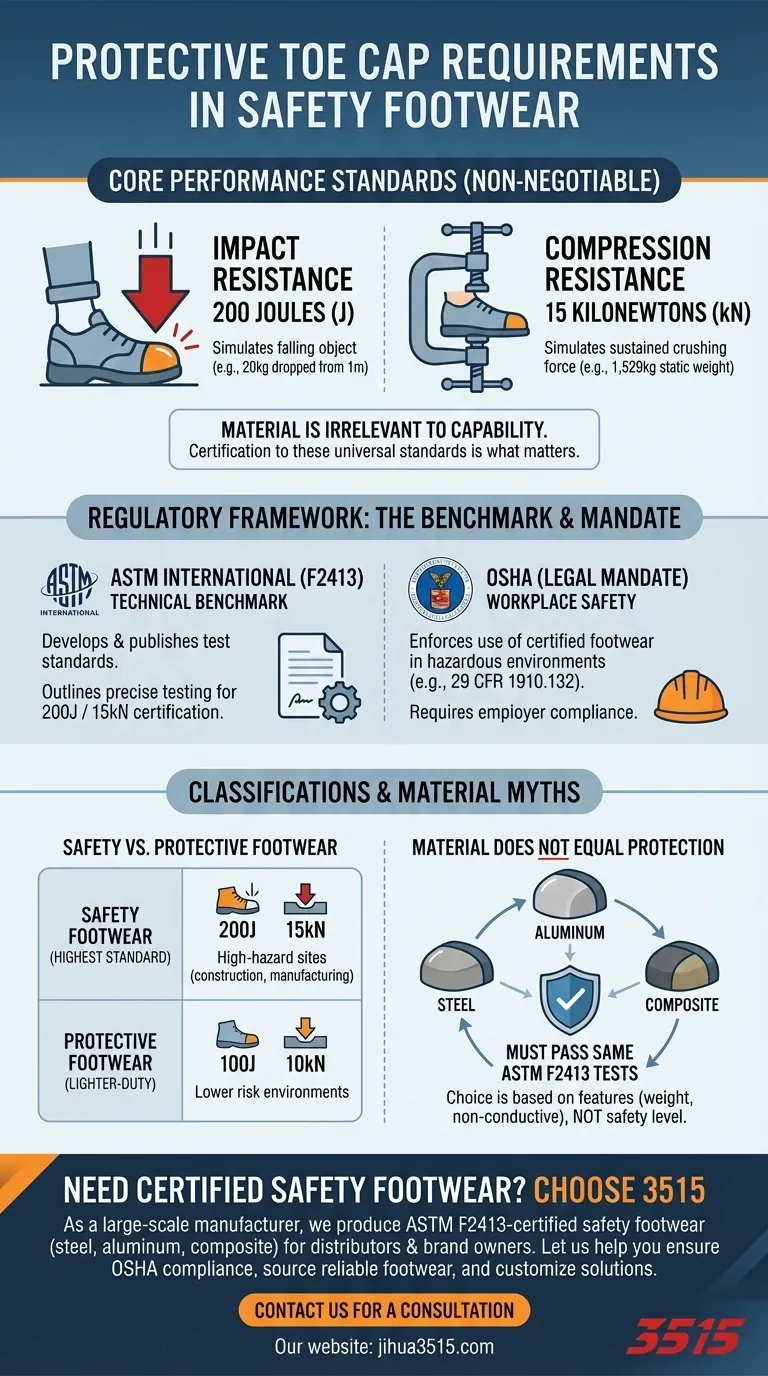

At its core, a protective toe cap in safety footwear must meet two non-negotiable performance standards. It must be able to withstand an impact of 200 Joules from a drop test and resist a static compression force of 15 kilonewtons (kN). These requirements are the benchmark for what is considered true "safety footwear."

The specific material used for a toe cap—whether steel, aluminum, or a non-metallic composite—is irrelevant to its protective capability. What matters is that it has been independently tested and certified to meet the universal impact and compression standards set by organizations like ASTM International.

Deconstructing the Performance Standards

To understand the requirements, we must look at the two distinct forces a safety toe is designed to protect against: a sudden impact from a falling object and a sustained crushing force from a rolling object.

The Impact Test (200 Joules)

The 200 Joule (J) rating measures the toe cap's ability to protect against a direct blow from above. This is simulated in a "drop test."

While the physics are complex, you can think of 200 Joules as the energy generated by a 20-kilogram (approx. 44 lbs) object dropped from a height of one meter (approx. 3.3 feet). The toe cap must withstand this impact without fracturing or deforming to a point that would injure the foot.

The Compression Test (15 kN)

The 15 kilonewton (kN) rating measures the toe cap's resistance to a slow, crushing force, simulating a scenario where a heavy object rolls onto the foot.

A force of 15 kN is equivalent to approximately 1,529 kilograms (or nearly 3,400 lbs) of static weight. The toe cap must endure this immense pressure to protect the toes from being crushed.

The Regulatory Framework: ASTM and OSHA

These numbers are not arbitrary; they are part of a structured system managed by technical and governmental bodies to ensure worker safety.

ASTM F2413: The Technical Benchmark

ASTM International (formerly the American Society for Testing and Materials) is the organization that develops and publishes the technical standards.

The standard ASTM F2413 is the primary specification for performance requirements for protective footwear. It outlines the precise testing methods and criteria, including the 200 J impact and 15 kN compression tests, that a boot must pass to be certified.

OSHA: The Legal Mandate

The Occupational Safety and Health Administration (OSHA) is the U.S. government agency that enforces workplace safety.

OSHA does not write the test standards itself. Instead, it requires employers to ensure their employees use protective footwear in any environment where foot injuries from falling objects, rolling objects, or electrical hazards are present. OSHA regulations (like 29 CFR 1910.132) mandate that this footwear must meet the standards set by organizations like ASTM.

Understanding the Classifications and Trade-offs

Not all protective footwear is created equal. The standards allow for different levels of protection based on the anticipated workplace hazards.

Safety Footwear: The Highest Standard

This is the category most people think of. It adheres to the 200 Joule impact and 15 kN compression ratings. It is intended for high-hazard environments like construction sites, manufacturing plants, and warehouses.

Protective Footwear: A Lighter-Duty Option

A lower classification exists for "protective" shoes, which are tested to a lesser standard of 100 Joule impact and 10 kN compression. This category is suitable for work environments with lower risks of severe impact or crushing injuries.

Material Does Not Equal Protection

A common misconception is that one material, like steel, is inherently "stronger" or "safer" than another, like a composite.

This is false. All materials must pass the exact same ASTM F2413 tests to earn the same safety rating. The choice between steel, aluminum, or composite is a matter of secondary features like weight, cost, or whether a non-metallic, non-conductive toe is needed.

Making the Right Choice for Your Goal

Your decision should always be based on a thorough hazard assessment of the work environment.

- If your primary focus is compliance in a high-hazard industry: You must select footwear explicitly certified to ASTM F2413 with the highest ratings for impact (I/75) and compression (C/75), which correspond to the 200 J and 15 kN standards.

- If your primary focus is on a specific feature like weight or thermal conductivity: You can choose between steel, aluminum, or composite materials, but only after confirming that the specific model meets the required ASTM protection level for your workplace.

- If your primary focus is a lower-risk environment: You may consider "protective" footwear with a lower rating, but you must first verify that this level of protection is sufficient according to your official risk assessment.

Ultimately, understanding these foundational requirements empowers you to look beyond marketing claims and select footwear based on certified, life-saving performance standards.

Summary Table:

| Requirement | Test Standard | Real-World Equivalent |

|---|---|---|

| Impact Resistance | 200 Joules | 20kg object dropped from 1m height |

| Compression Resistance | 15 kN | 1,529kg (3,400 lbs) of static weight |

Need Safety Footwear That Meets All Standards?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM F2413-certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective shoes and boots with steel, aluminum, and composite toe caps that meet the highest safety requirements.

Let us help you:

- Ensure full OSHA compliance for your workforce

- Source reliable, certified safety footwear at scale

- Customize solutions for your specific industry hazards

Contact us today for a consultation and get footwear that truly protects.

Visual Guide

Related Products

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- How do metatarsal guards enhance work shoe safety? Prevent Crushing Foot Injuries on the Job

- How are steel and composite toe caps tested for safety? Discover the Uniform Standard

- How does puncture-resistant (PR) safety footwear work? The Ultimate Guide to Underfoot Protection

- What are the advantages of KPU moulding material for labour protection shoes? Superior Durability & Comfort

- What are the key protective features of safety shoes? Essential Guide for Workplace Safety