To put it simply, the primary types of safety toe boots are steel toe, composite toe, and alloy toe. Each uses a different material for the protective toe cap, offering a distinct blend of protection, weight, and suitability for various work environments.

The core decision is not about finding the "strongest" toe but about matching the material's specific properties—like weight, conductivity, and cost—to the unique demands and hazards of your job.

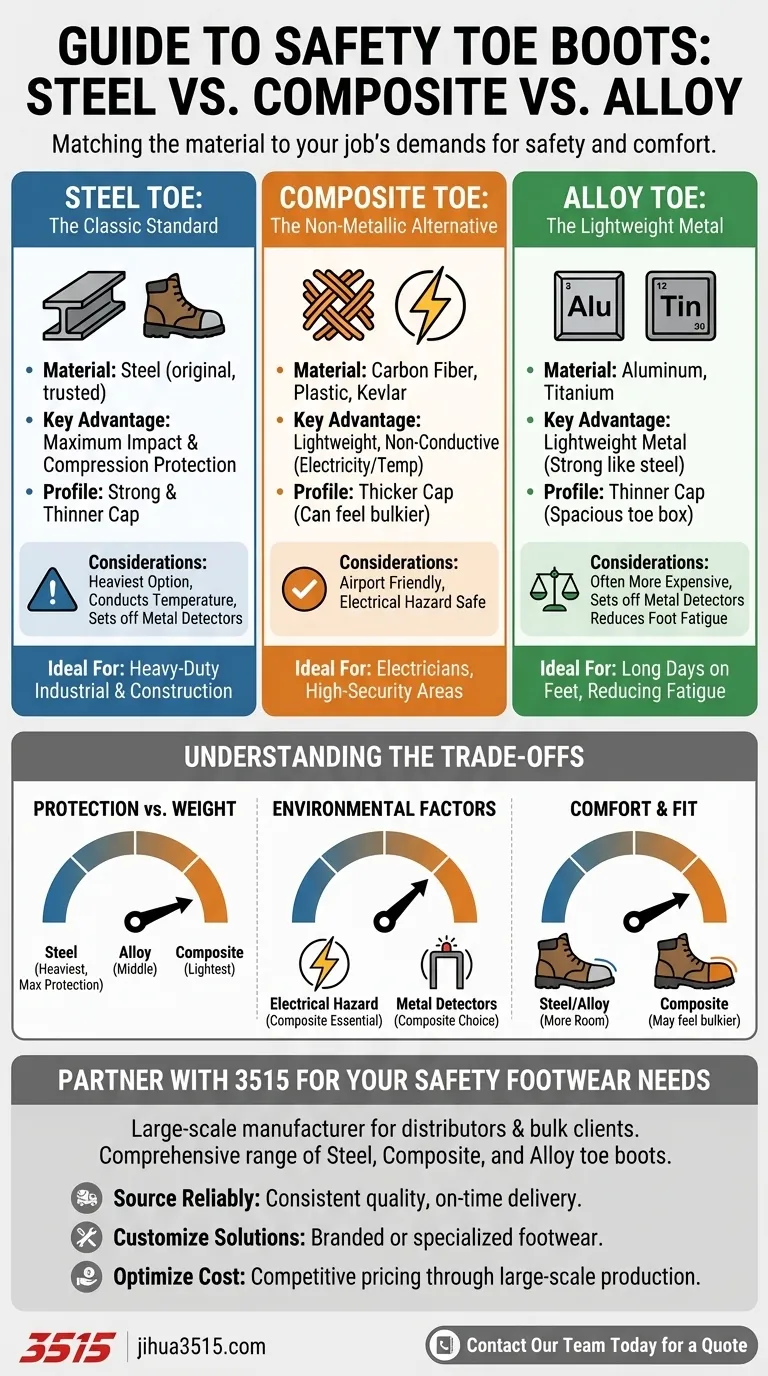

Breaking Down the Safety Toe Materials

Choosing the right safety boot begins with understanding the fundamental differences between the materials used in the protective toe cap. Each has been engineered to solve a specific set of problems on the job site.

Steel Toes: The Classic Standard

Steel was the original material for safety toes and remains a trusted standard for heavy-duty protection. It offers maximum resistance to impact and compression.

The primary advantage of steel is its strength. Because it's so robust, the toe cap can be made thinner than other materials while still meeting safety standards, resulting in a less bulky boot profile.

However, steel is the heaviest option and readily conducts temperature, making it potentially uncomfortable in extreme heat or cold. It will also set off metal detectors.

Composite Toes: The Non-Metallic Alternative

Composite toes are crafted from non-metallic materials like carbon fiber, plastic, or Kevlar. This makes them a popular choice for electricians or workers in high-security areas.

Their key benefit is being lightweight and non-conductive of electricity or temperature. This makes them ideal for environments with electrical hazards or where metal detectors are present.

While they meet the same ASTM safety standards as steel, the composite cap must be thicker to provide equivalent protection, which can sometimes make the boot feel bulkier in the toe box.

Alloy Toes: The Lightweight Metal

Alloy toes, typically made from materials like aluminum or titanium, offer a modern compromise. They provide the strength of a metal toe cap but are significantly lighter than steel.

These boots are often 30-50% lighter than their steel-toed counterparts, reducing foot fatigue over a long day. Like steel, they are thinner than composite caps, allowing for a more spacious toe box.

The main trade-off is often cost, as alloy toe boots can be more expensive. They are also metallic and will set off metal detectors.

Understanding the Trade-offs

No single safety toe is universally superior; each comes with a set of compromises. Your choice directly impacts your daily comfort and safety.

Protection vs. Weight

While all certified safety toes meet the same impact and compression standards, their weight differs significantly. Steel is heaviest, alloy is in the middle, and composite is the lightest. This weight difference becomes a major factor in foot fatigue by the end of a shift.

Environmental Factors

Your work environment is a critical consideration. If you work around live circuits, a non-metallic composite toe is essential for electrical hazard protection. If you pass through metal detectors frequently, composite is again the clear choice.

Comfort and Fit

The thickness of the toe cap material affects the internal space of the boot. Steel and alloy caps can be thinner, potentially offering more room. A thicker composite cap might make the boot feel bulkier, so trying them on is crucial.

Making the Right Choice for Your Goal

Ultimately, the best boot depends entirely on your priorities and the hazards you face.

- If your primary focus is maximum protection in a heavy industrial or construction setting: Steel toe offers time-tested, heavy-duty performance at a great value.

- If your primary focus is working in an environment with electrical hazards or metal detectors: Composite toe is the non-negotiable choice for safety and convenience.

- If your primary focus is reducing foot fatigue without sacrificing metal's strength: Alloy toe provides a lightweight, comfortable solution for long days on your feet.

Selecting the right safety toe is a foundational step in ensuring both your safety and your comfort on the job.

Summary Table:

| Safety Toe Type | Core Material | Key Advantage | Main Consideration | Ideal For |

|---|---|---|---|---|

| Steel Toe | Steel | Maximum impact/compression protection | Heaviest; conducts temperature | Heavy-duty industrial work |

| Composite Toe | Carbon Fiber, Kevlar | Lightweight; non-conductive | Thicker cap can feel bulkier | Electrical hazards, high-security areas |

| Alloy Toe | Aluminum, Titanium | Lightweight metal; strong | Often more expensive | Reducing foot fatigue without sacrificing strength |

Ready to Equip Your Team with the Right Safety Boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of steel toe, composite toe, and alloy toe boots, ensuring you get the perfect combination of safety, comfort, and durability for your specific needs.

We help you:

- Source Reliably: Get consistent quality and on-time delivery for your orders.

- Customize Solutions: Develop branded or specialized footwear tailored to your market.

- Optimize Cost: Benefit from competitive pricing through our efficient large-scale production.

Let's discuss your requirements. Contact our team today for a quote and see how we can become your trusted manufacturing partner.

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What factors should be considered when choosing the appropriate type of safety footwear? A Guide to Maximum Protection

- What standards must protective footwear meet? A Guide to ASTM F2413 and F2412 Compliance

- What are the benefits of a composite toe? Discover Lighter, Safer, and More Comfortable Work Footwear

- Why is waterproofing important in motorcycle boots? Stay Safe and Comfortable on Every Ride

- How does high-performance safety footwear protect against pathogens? Secure the Biological Safety Perimeter

- Why is moisture management a critical design feature for safety boots? Boost Mining Safety and Worker Skin Health.

- In what ways do shoes protect your feet? Essential Safety Features Explained

- Why is appropriate work footwear important on job? Essential Guide to Safety & Compliance