When choosing between steel and composite toe caps, the decision hinges on four key factors: your work environment's electrical and temperature hazards, the physical demands of your job, your budget, and personal comfort. Both materials are required to meet the same ASTM F2413 safety standards for impact and compression, meaning one is not inherently "safer" than the other from a purely protective standpoint.

The core decision is not about which material offers better protection, but which provides the right properties for your specific job. Steel is the cost-effective, traditional standard, while composite offers a modern, lightweight, and non-conductive alternative for specialized environments.

The Foundation: Equal Safety Standards

Before comparing differences, it's critical to understand that both materials start from the same baseline of certified protection. This ensures your choice is about features, not fundamental safety.

The ASTM F2413 Standard

All legitimate safety footwear, whether steel or composite, must be tested and certified to meet the ASTM F2413 standard. This means both have passed identical tests for impact and compression resistance, giving you proven protection against falling objects and crushing forces.

What "Composite" Actually Means

The term "composite" refers to non-metallic materials. These toe caps are typically crafted from a blend of advanced materials like Kevlar, carbon fiber, fiberglass, and specialized plastics. This construction is what gives them their unique properties.

Key Differentiating Factors

The best choice for you emerges when you analyze how the properties of steel and composite materials align with your daily tasks and work environment.

Weight and All-Day Comfort

Composite toe caps are significantly lighter than steel toe caps. While this may seem minor, the weight difference reduces fatigue over a long workday, especially for those who walk or stand for extended periods.

Conductivity and Environmental Hazards

This is the most critical safety differentiator. Steel is a conductor of heat, cold, and electricity. Composite materials are non-conductive, making them insulators.

If you work in extreme cold or heat, a steel toe will transfer those temperatures to your foot. More importantly, for electricians or anyone working near live circuits, a non-conductive composite toe is an essential safety feature.

Cost and Style Availability

Steel has been the industry standard for decades. As a result, steel toe boots are generally less expensive and are available in a much wider variety of styles and brands. Composite technology is newer and more costly to produce, which is reflected in the final price.

Understanding the Trade-offs

Choosing between steel and composite is an exercise in balancing priorities. Neither option is perfect for every situation.

The Steel Toe Compromise

With a steel toe, you gain cost savings and proven durability. The trade-off is accepting greater weight, which can lead to fatigue, and full conductivity, which makes it unsuitable for certain electrical or temperature-extreme environments.

The Composite Toe Compromise

With a composite toe, you gain superior comfort from its lighter weight and enhanced safety from its non-conductive properties. The trade-off is a higher initial cost and potentially fewer style options to choose from. After a significant impact, a composite cap should be replaced, as damage may not be visible.

Making the Right Choice for Your Role

To select the best safety toe, align its core characteristics with your primary job requirements.

- If your primary focus is cost-effectiveness in a standard construction or manufacturing role: Steel toe is the reliable, budget-friendly industry standard.

- If your primary focus is all-day comfort and reducing leg fatigue: The significantly lighter weight of a composite toe is the superior choice for active jobs.

- If you work with or near live electrical hazards: A non-conductive composite toe is a non-negotiable safety requirement.

- If you work in extreme outdoor heat or cold: A non-conductive composite toe will provide significantly more comfort by not transferring temperatures.

Ultimately, choosing the right safety toe is about selecting the smartest material for your specific workday.

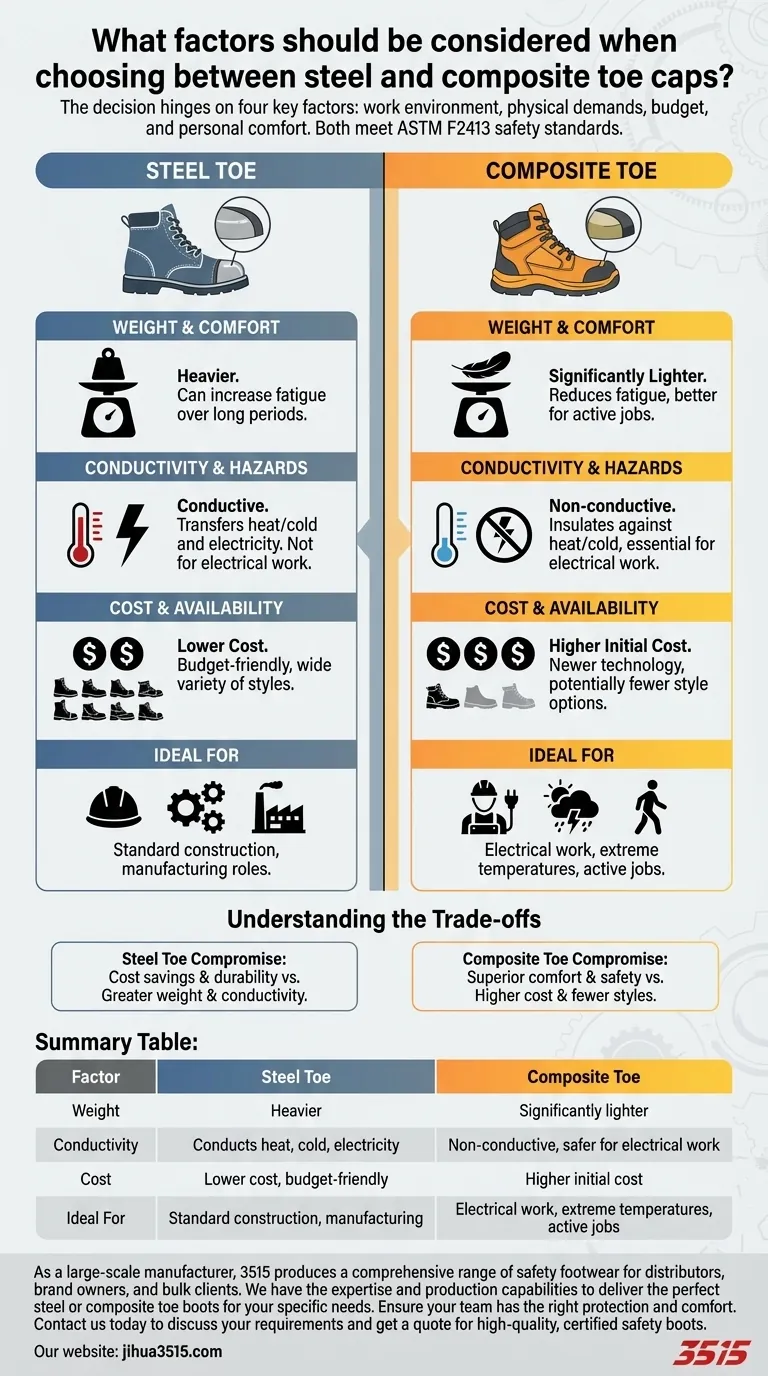

Summary Table:

| Factor | Steel Toe | Composite Toe |

|---|---|---|

| Weight | Heavier | Significantly lighter |

| Conductivity | Conducts heat, cold, electricity | Non-conductive, safer for electrical work |

| Cost | Lower cost, budget-friendly | Higher initial cost |

| Ideal For | Standard construction, manufacturing | Electrical work, extreme temperatures, active jobs |

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. We have the expertise and production capabilities to deliver the perfect steel or composite toe boots for your specific needs.

Ensure your team has the right protection and comfort. Contact us today to discuss your requirements and get a quote for high-quality, certified safety boots.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What are the common problems with steel toe boots? How to Prevent Foot Pain & Fatigue

- How does composite toe compare to steel toe? Choose the Right Safety for Your Job

- What role do steel-toe safety shoes play in high-rise construction? Essential PPE for Vertical Build Security

- In what work environments are steel-toe boots recommended? Essential Safety for High-Risk Industries

- How do alloy and aluminum toes compare to steel toes? Lighter, Thinner, More Comfortable.

- What are the benefits of steel toe caps? Maximum Impact Protection & Durability

- What causes corns in steel toe boots and how can they be prevented? Master the Perfect Fit to Avoid Pain

- In which work environments are steel toe shoes particularly necessary? Essential for Construction, Warehousing & More