When choosing safety footwear, the primary difference is not in the level of protection but in weight and comfort. Alloy and aluminum toes meet the same official safety standards as steel toes, but they accomplish this at a significantly lower weight—often 30-50% lighter. This makes them a superior choice for reducing fatigue over long workdays.

The decision between steel, alloy, and aluminum safety toes is not a matter of which is "safer," as all certified options provide the same impact and compression resistance. The real choice is a trade-off between weight, toe-box volume, and material properties that affect all-day comfort.

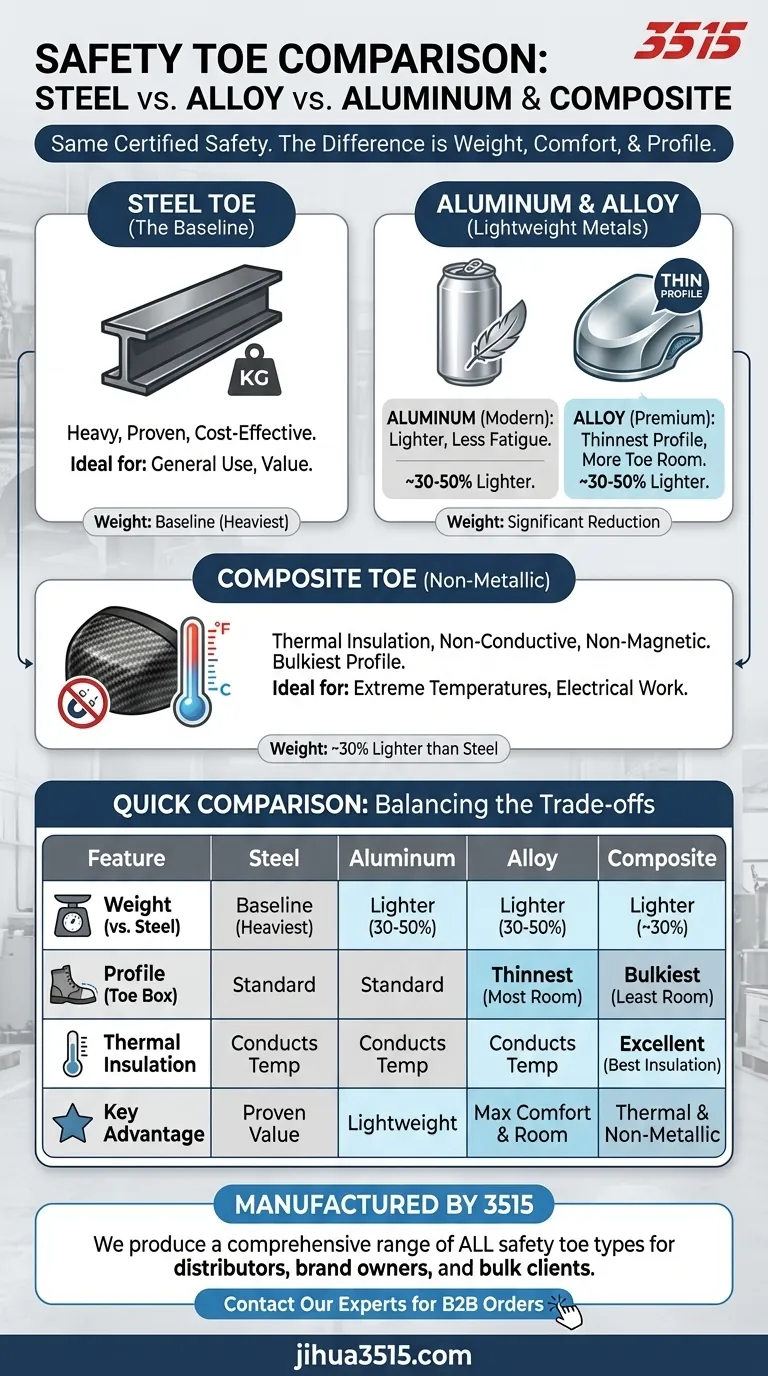

The Core Comparison: Steel vs. Lighter Metals

To make an informed choice, it's essential to treat steel as the baseline and understand how the alternatives improve upon its characteristics.

The Foundation: Steel Toes

Steel is the traditional material for safety toes. It offers exceptional strength and has been the industry standard for decades, providing a reliable and often cost-effective solution for foot protection.

Its primary drawback is its weight, which can contribute to leg fatigue during extended wear.

The Modern Alternative: Aluminum Toes

Aluminum toes deliver the same level of impact protection as steel but are a much lighter material.

By significantly reducing the weight at the end of your foot, aluminum caps can make boots feel more comfortable and less cumbersome, especially after many hours on your feet.

The Premium Option: Alloy Toes

Alloy toes are typically made from a blend of lightweight metals like titanium and aluminum. They represent the peak of modern safety toe technology.

Not only are they 30-50% lighter than steel, but they are also stronger, allowing them to be engineered with a thinner profile. This creates more room inside the boot's toe box, a critical feature for comfort.

Expanding the Field: Why Composite Toes Matter

While you asked about metals, no discussion is complete without understanding the most common non-metallic alternative: composite toes.

The Non-Metallic Choice: Composite Toes

Composite toes, made from materials like carbon fiber, fiberglass, or Kevlar, are a popular metal-free option. They are approximately 30% lighter than steel.

Because these materials are not as inherently strong as metal, a composite cap must be thicker and bulkier to meet the same safety standards, which can reduce space in the toe box.

The Key Advantage: Thermal Insulation

The most significant benefit of composite toes is their lack of thermal conductivity.

Unlike steel, aluminum, or alloy, composite materials do not transfer cold or heat. This makes them vastly superior for anyone working in extreme high or low temperatures.

Understanding the Trade-offs

Choosing the right material requires balancing its benefits against its inherent compromises.

Weight vs. Bulk

Steel is the heaviest. Alloy and aluminum are the lightest.

However, composite toes, while lighter than steel, are typically the bulkiest of all options to achieve the required safety rating. For those who value a roomy toe box, a thin-profile alloy toe is often the best choice.

Strength vs. Profile

The high strength of metal allows for a thinner protective cap. Alloy toes are the strongest and therefore can be the thinnest.

This thin profile not only increases comfort but can also give the footwear a sleeker, less "industrial" appearance.

Environmental Factors

If you work in extreme cold or heat, a metal toe cap will conduct that temperature directly to your foot, causing significant discomfort. Composite is the only practical choice for these environments.

Furthermore, composite toes are non-magnetic and do not conduct electricity, making them essential for electricians or workers who pass through metal detectors frequently.

Making the Right Choice for Your Work

Select your safety toe material based on the primary demands of your job.

- If your primary focus is maximum all-day comfort and toe room: An alloy toe is your best option due to its combination of the lowest weight and thinnest profile.

- If your primary focus is working in extreme cold or heat: A composite toe is the only choice that will insulate your feet from the temperature.

- If your primary focus is a balance of proven protection and value: The traditional steel toe remains a reliable and cost-effective standard.

- If your primary focus is a lightweight, metal-free boot: A composite toe provides certified safety without conducting electricity or setting off metal detectors.

Ultimately, understanding these material differences empowers you to choose safety footwear based on your specific daily demands, not just a generic safety rating.

Summary Table:

| Feature | Steel Toe | Aluminum Toe | Alloy Toe | Composite Toe |

|---|---|---|---|---|

| Weight (vs. Steel) | Baseline (Heaviest) | 30-50% Lighter | 30-50% Lighter | ~30% Lighter |

| Toe-Box Profile | Standard | Standard | Thinnest | Bulkiest |

| Key Advantage | Cost-Effective & Proven | Lightweight Metal | Lightweight & Roomy | Thermal Insulation, Non-Metallic |

| Ideal For | General Use, Value | Reducing Leg Fatigue | Maximum All-Day Comfort | Extreme Temperatures, Electrical Work |

Find Your Perfect Fit with 3515 Manufacturer

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of steel toe, alloy toe, aluminum toe, and composite toe boots, ensuring you get the precise combination of protection, comfort, and value your customers need.

Ready to equip your workforce with superior safety footwear? Contact our experts today to discuss your requirements and discover how we can support your business.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- Is safety-toe as good as steel toe? Choose the Right Protection for Your Job

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- Do snake bite boots work? Your Ultimate Guide to Effective Snake Bite Protection

- How long can you wear safety boots? The Lifespan is Determined by Wear, Not Time