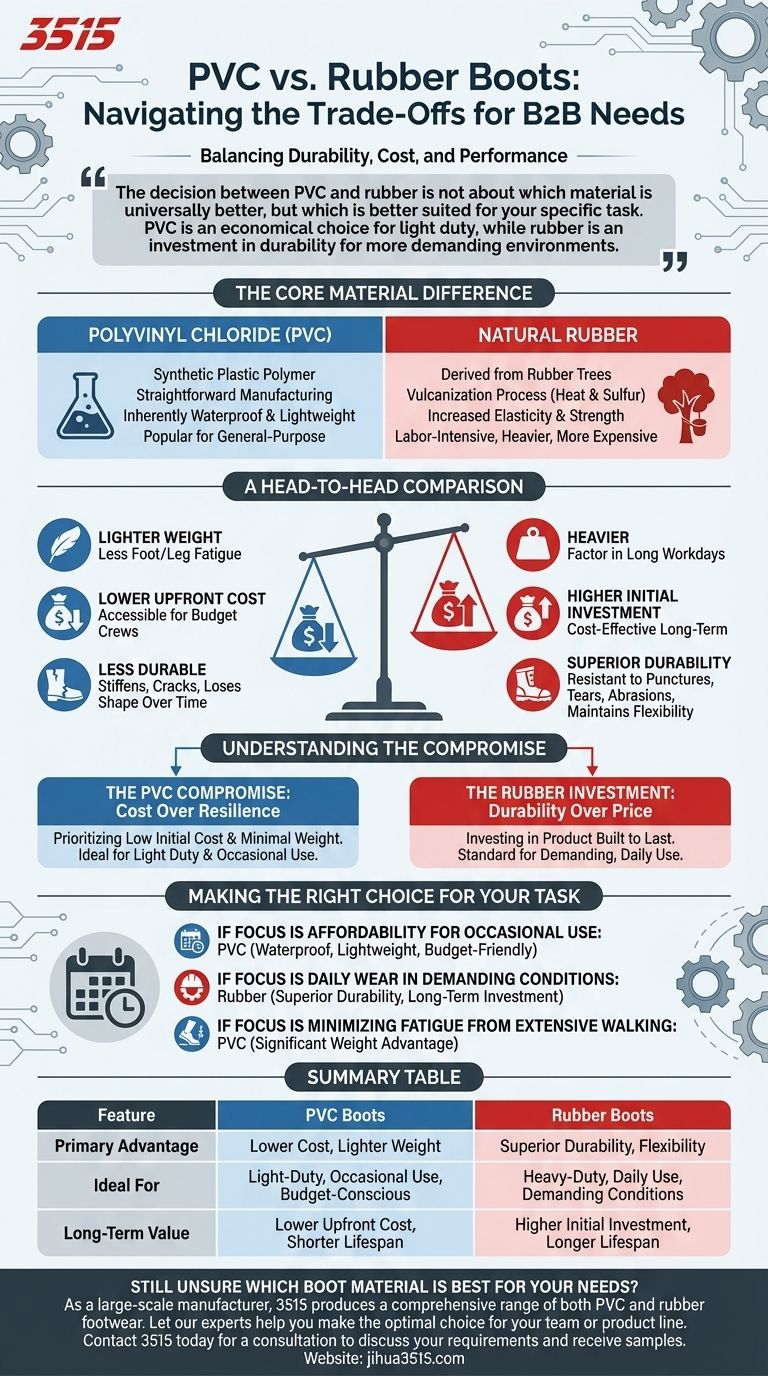

When choosing between PVC and rubber boots, the primary trade-off is sacrificing long-term durability for a lower initial cost and lighter weight. PVC boots are more affordable and easier to wear for long periods of walking, but they are stiffer and less resilient than their natural rubber counterparts, which offer superior durability at a higher price and weight.

The decision between PVC and rubber is not about which material is universally better, but which is better suited for your specific task. PVC is an economical choice for light duty, while rubber is an investment in durability for more demanding environments.

The Core Material Difference

To understand the trade-offs, it's essential to understand what each material is. They are fundamentally different, which directly impacts their performance, cost, and longevity.

Polyvinyl Chloride (PVC)

PVC is a synthetic plastic polymer. Its manufacturing process is straightforward and cost-effective, which is why PVC boots are significantly more affordable.

This material is inherently waterproof and lightweight, making it a popular choice for general-purpose boots.

Natural Rubber

Natural rubber is derived from the latex of rubber trees. This raw material undergoes a process called vulcanization, which involves heating it with sulfur to improve its elasticity and strength.

This labor-intensive process makes natural rubber boots heavier and more expensive, but it also gives them their hallmark durability and flexibility.

A Head-to-Head Comparison

Each material's properties create a distinct set of advantages and disadvantages in the field.

Durability and Longevity

Natural rubber has a clear advantage in durability. It is more resistant to punctures, tears, and abrasions, and it maintains its flexibility over a longer lifespan.

PVC is less durable. Over time, it can become stiff, lose its original shape, and is more susceptible to cracking, especially with heavy use.

Weight and User Fatigue

PVC is significantly lighter than rubber. This is a major benefit for jobs that require frequent or extensive walking, as it can noticeably reduce foot and leg fatigue.

The density and vulcanization process make rubber boots heavier, which can be a factor during long workdays.

Cost: Upfront vs. Long-Term

PVC boots have a much lower upfront cost, making them an accessible option for occasional use or for outfitting a large crew on a budget.

Rubber boots require a higher initial investment. However, their extended lifespan in demanding conditions can often make them more cost-effective over the long term, as they need to be replaced less frequently.

Understanding the Trade-offs

The choice between these two materials comes down to balancing your immediate needs with long-term performance expectations.

The PVC Compromise: Cost Over Resilience

When you choose PVC, you are prioritizing a low initial cost and minimal weight. The compromise is in durability and long-term comfort.

These boots are ideal for situations where they won't be subjected to constant, heavy abuse and where budget is a primary driver.

The Rubber Investment: Durability Over Price

Opting for rubber means you are investing in a product built to last. You accept a higher upfront cost and a heavier boot in exchange for superior resilience and longevity.

This is the standard for industries and tasks where boots face harsh conditions daily and reliability is non-negotiable.

Making the Right Choice for Your Task

Your specific application should be the deciding factor.

- If your primary focus is affordability for occasional use: PVC boots offer a waterproof, lightweight, and budget-friendly solution.

- If your primary focus is daily wear in demanding conditions: The superior durability and resilience of rubber boots make them a worthwhile long-term investment.

- If your primary focus is minimizing fatigue from extensive walking: The lighter weight of PVC can be a significant advantage over heavier rubber alternatives.

Choosing the right material ensures your footwear is an asset, not a liability.

Summary Table:

| Feature | PVC Boots | Rubber Boots |

|---|---|---|

| Primary Advantage | Lower Cost, Lighter Weight | Superior Durability, Flexibility |

| Ideal For | Light-Duty, Occasional Use, Budget-Conscious | Heavy-Duty, Daily Use, Demanding Conditions |

| Long-Term Value | Lower Upfront Cost, Shorter Lifespan | Higher Initial Investment, Longer Lifespan |

Still Unsure Which Boot Material is Best for Your Needs?

As a large-scale manufacturer, 3515 produces a comprehensive range of both PVC and rubber footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of work boots, ensuring you get the right combination of durability, comfort, and value for your specific application.

Let our experts help you make the optimal choice for your team or product line.

Contact 3515 today for a consultation to discuss your requirements and receive samples.

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- High Performance Fire-Retardant Waterproof Safety Boots

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- Who would benefit from investing in gumboots? Unlock Protection for Work & Play

- How did Wellington boots transition to civilian use? A Lesson in Innovation and Adaptation

- What are the drawbacks of rubber gardening shoes? Understanding the Trade-offs of Waterproof Footwear

- How is natural rubber different from synthetic materials like PVC and Neoprene in boots?

- What activities are Wellington boots suitable for? A Guide to Dry Feet in Any Environment

- What are the characteristics of EVA rain boots? Lightweight Comfort for Casual & Recreational Use

- What materials are used in the construction of PVC boots? A Guide to Durable, Waterproof Footwear

- Why are rubber boots suitable for outdoor play in the rain? For Ultimate Waterproof Protection