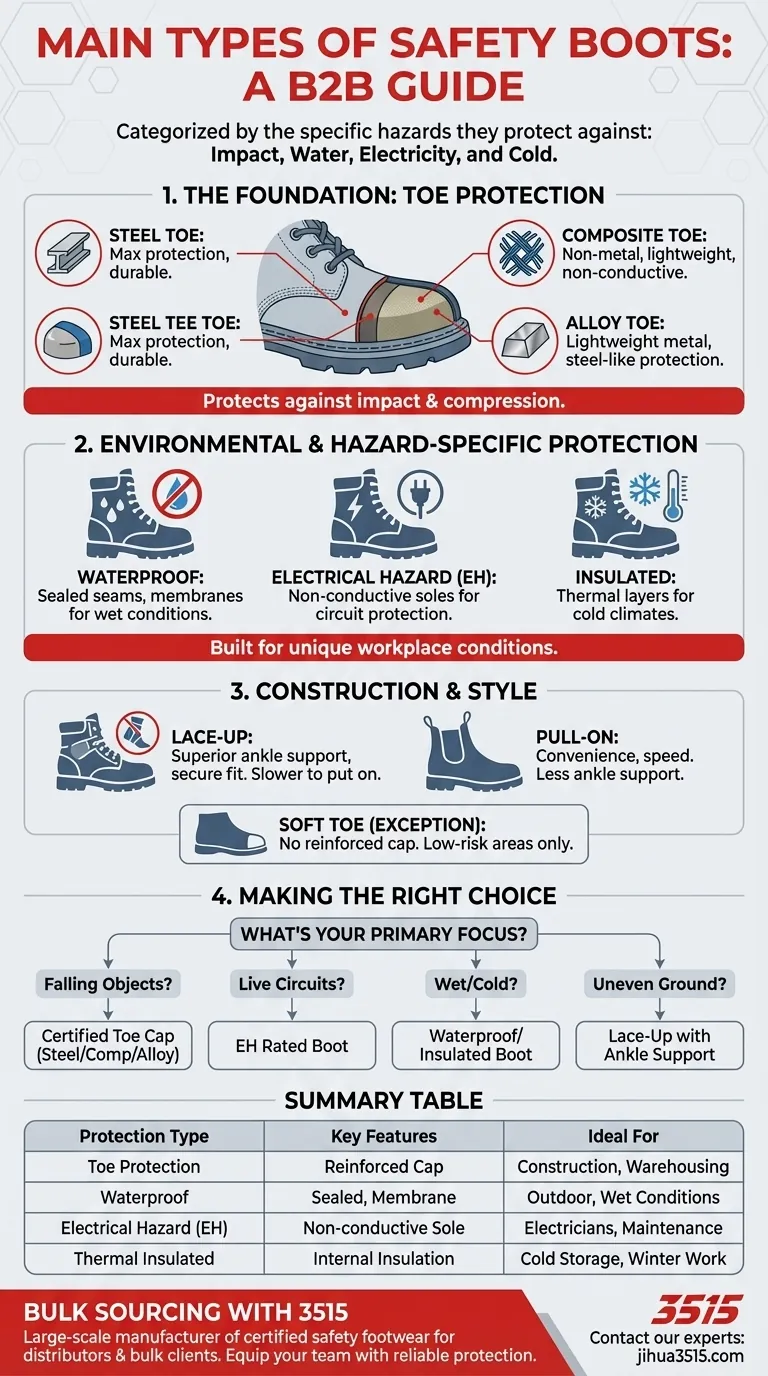

In short, safety boots are categorized by the specific hazards they protect against. The primary types discussed are those offering toe protection, waterproofing, electrical hazard resistance, and thermal insulation. Each is designed to mitigate risks in specific work environments, from construction sites to refrigerated warehouses.

The most critical distinction in safety footwear isn't about style, but function. Choosing the right boot requires matching its specific protective features—like the type of toe cap or its electrical rating—to the known hazards of your job.

Deconstructing Safety Boot Features

The term "safety boot" is a broad category. To understand the options, we must break them down by the specific protection they offer. A single boot can, and often does, incorporate multiple safety features.

The Foundation: Toe Protection

This is the most fundamental feature of a safety boot. It involves a reinforced cap integrated into the front of the boot to protect against impact and compression from heavy objects.

The main materials used for this reinforcement are:

- Steel Toe: The traditional standard, known for maximum protection and durability.

- Composite Toe: Made from non-metal materials like carbon fiber or plastic. They are lighter and don't conduct heat, cold, or electricity.

- Alloy Toe: Constructed from lightweight metals like aluminum or titanium, offering protection similar to steel but with less weight.

Environmental & Hazard-Specific Protection

Beyond toe protection, boots are designed to handle specific environmental conditions and unique workplace hazards.

- Waterproof Boots: Essential for outdoor work or jobs involving wet conditions. These boots use waterproof membranes and sealed seams to keep feet dry and prevent discomfort or health issues.

- Electric Hazard (EH) Boots: These are built with non-conductive soles and heels to protect the wearer from open electrical circuits. This is a critical feature for electricians and maintenance workers.

- Insulated Boots: Designed for cold environments, these boots incorporate insulation to maintain foot temperature and prevent frostbite. They are crucial for those working in refrigeration, cold climates, or winter conditions.

Understanding the Trade-offs: Construction & Style

The way a boot is constructed significantly impacts its performance, comfort, and suitability for a given task. While not a "safety feature" in the same way as a steel toe, the construction method is a vital consideration.

Lace-Up vs. Pull-On

The two most common construction styles each have distinct advantages and disadvantages.

- Lace-Up Boots: Offer a secure, adjustable fit that provides superior ankle support. This is critical for walking on uneven terrain where a twisted ankle is a constant risk. However, they can be slower to put on and take off.

- Pull-On Boots: Provide convenience and speed, making them easy to slip on and off. They often offer better protection against debris or splashes falling into the boot but typically provide less ankle support than their lace-up counterparts.

Soft Toe: The Exception

It's important to note the existence of soft toe boots. While they are a type of work boot, they lack a reinforced protective toe cap. They are suitable only for jobs where impact and compression hazards are not present.

Making the Right Choice for Your Goal

Selecting the correct boot is a matter of matching its features to your specific work environment and its associated risks.

- If your primary focus is protection from falling objects: Prioritize a boot with a certified steel, composite, or alloy toe cap.

- If your primary focus is working around live circuits: You must select a boot with an explicit Electric Hazard (EH) rating.

- If your primary focus is working in wet or cold conditions: Look for boots with genuine waterproof membranes and thermal insulation.

- If your primary focus is stability on uneven ground: Choose a lace-up boot that provides firm and reliable ankle support.

Ultimately, understanding the specific hazards you face is the first and most important step in choosing the right protection for your feet.

Summary Table:

| Protection Type | Key Features | Ideal For |

|---|---|---|

| Toe Protection | Steel, Composite, or Alloy Toe Cap | Construction, Warehousing |

| Waterproof | Sealed seams, waterproof membrane | Outdoor work, wet conditions |

| Electrical Hazard (EH) | Non-conductive sole & heel | Electricians, Maintenance |

| Thermal Insulated | Internal insulation | Cold storage, winter work |

Need to source the right safety boots in bulk?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. We ensure your workforce has the precise protection they need, from steel toe boots to EH-rated and insulated models.

Let us help you equip your team with reliable, high-quality footwear.

Contact our experts today to discuss your requirements

Visual Guide

Related Products

- Premium Waterproof Nubuck Safety Boots for Wholesale

- Durable Steel Toe Safety Boots Wholesale & Custom Manufacturing

- High Performance Fire-Retardant Waterproof Safety Boots

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium KPU Injection Athletic Style Safety Shoes

People Also Ask

- What standards must safety toe boots meet? Ensure Your Footwear Meets ASTM F2413

- What tips can help ensure safety toe boots fit correctly? Achieve Optimal Protection & Comfort

- How does routine boot maintenance benefit workplace safety? Proactive PPE Protection for Your Workforce

- What additional safety equipment might be needed with work boots? Complete Your PPE System for Total Protection

- What other types of protective workwear are commonly used on worksites? Essential PPE for Complete Safety