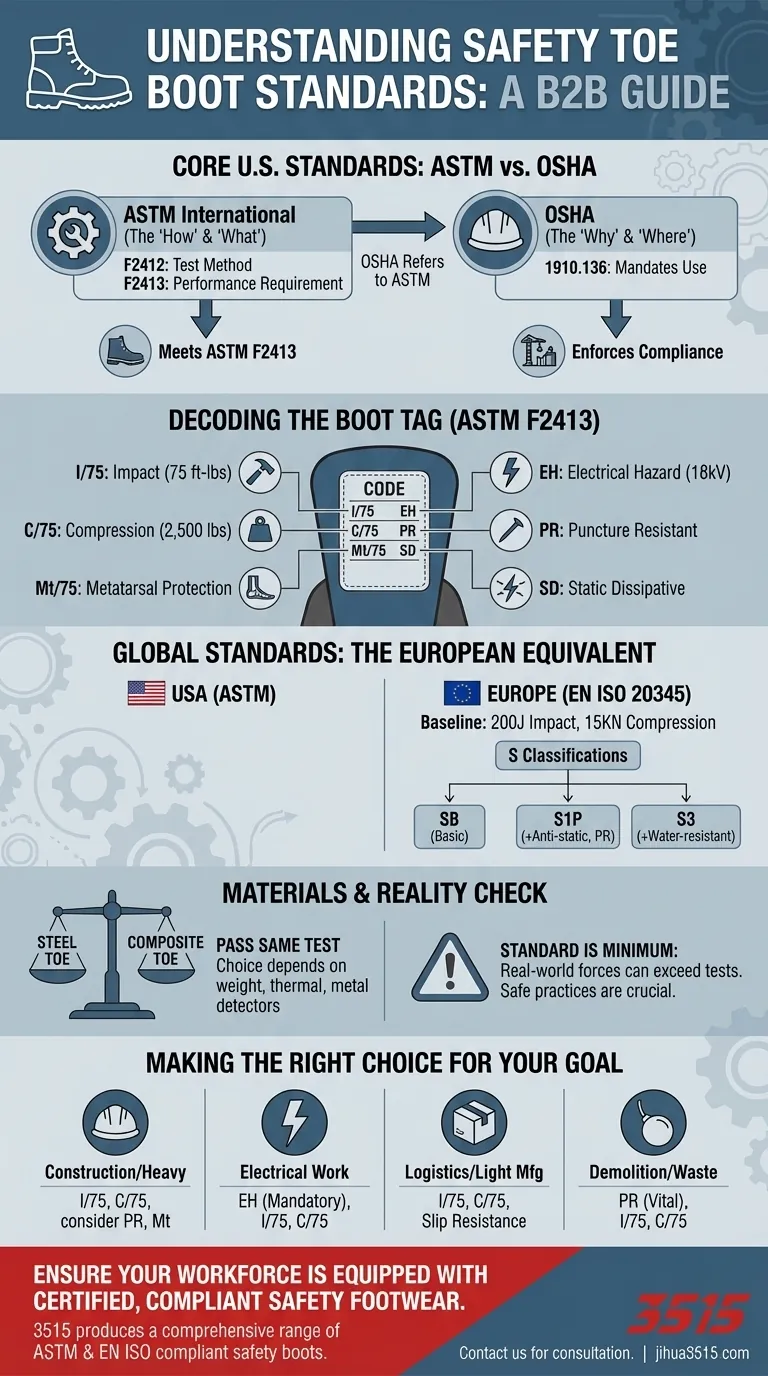

In the United States, all legitimate safety toe boots must meet the performance requirements of ASTM F2413. This standard, set by the American Society for Testing and Materials, is the benchmark for protective footwear. While OSHA (Occupational Safety and Health Administration) mandates the use of such footwear in hazardous environments, it is the ASTM standard that defines the specific safety criteria a boot must pass.

The codes and standards on a safety boot's tag are not just bureaucratic labels; they are a precise language that tells you exactly what hazards the boot is designed to protect you from. Understanding this language is the key to matching your gear to your specific worksite risks.

Decoding the Core U.S. Standards

To understand footwear compliance, you must know the distinct roles of ASTM and OSHA. One creates the test, and the other enforces its use.

The Role of ASTM: The "How" and "What"

ASTM International sets the technical standards for a vast range of products, including safety footwear. Two standards are critical here.

- ASTM F2412: This is the test method. It outlines the precise procedures for testing footwear for impact resistance, compression resistance, and other safety features.

- ASTM F2413: This is the performance requirement. It specifies the minimum performance levels that footwear must meet when subjected to the F2412 tests. This is the standard you will see referenced on the boot's tag.

Essentially, a boot is tested according to F2412 to prove that it meets F2413.

The Role of OSHA: The "Why" and "Where"

OSHA is the government agency responsible for ensuring safe and healthful working conditions.

OSHA's standard 1910.136 mandates that employers require protective footwear in workplaces where there is a danger of foot injuries. However, OSHA does not create its own footwear standard; it defers to standards like ASTM F2413 as a means of compliance.

Understanding the Safety Ratings on Your Boot's Tag

An ASTM F2413-compliant boot will have a tag (typically sewn inside the tongue) with a specific code. This code breaks down the boot's specific protections.

Impact (I) and Compression (C) Resistance

This is the foundational rating for any safety toe. It certifies the toe cap's ability to protect you from falling objects and crushing forces.

The rating is typically I/75 and C/75.

- I/75: The toe box can withstand an impact of 75 foot-pounds.

- C/75: The toe box can withstand a compressive load of 2,500 pounds.

Metatarsal (Mt) Protection

This rating indicates additional protection for the top of your foot (the metatarsal bones), which is vulnerable to drop hazards. If a boot has this, its tag will include Mt/75.

Electrical Hazard (EH) Protection

An EH rating signifies that the footwear is constructed with non-conductive, electrical-shock-resistant soles and heels. These boots are designed to protect the wearer from open circuits of up to 18,000 volts under dry conditions.

Other Key Protections

You may see other codes depending on the boot's intended use, such as:

- PR: Puncture Resistant footwear has a plate inside the sole to prevent sharp objects from penetrating.

- SD: Static Dissipative footwear reduces the buildup of static electricity.

Global Standards: The European Equivalent

While ASTM is the U.S. standard, you may encounter another, particularly if you work for an international company.

EN ISO 20345

This is the primary European standard for safety footwear. While the testing principles are similar to ASTM, the rating system is different.

The baseline requirement is a toe cap that can withstand 200 joules of impact and a compression test of 15 kilonewtons (KN).

The "S" Classifications

European standards use "S" codes to denote the package of protective features.

- SB: The basic safety standard (200-joule toe cap).

- S1P: Includes SB features plus anti-static properties and a puncture-resistant midsole.

- S3: Includes all S1P features plus a water-resistant upper.

Common Pitfalls and Key Considerations

Choosing the right boot goes beyond simply finding one that meets a standard.

Steel vs. Composite: Both Must Pass the Same Test

The material of the toe cap—be it steel, aluminum, or a composite material—does not change the standard. A composite toe boot rated I/75 C/75 has passed the exact same impact and compression tests as a steel toe boot with the same rating. The choice between them comes down to factors like weight, thermal conductivity, and whether you pass through metal detectors.

A Standard is a Minimum Requirement

Remember that these tests are performed in a controlled laboratory environment. A certified boot provides a specific, tested level of protection, but a real-world accident can involve forces that exceed any standard. Proper awareness and safe work practices are just as crucial as your personal protective equipment.

Making the Right Choice for Your Goal

Use the boot's tag to match its features to the specific hazards of your job.

- If your primary focus is construction or heavy industry: You need a boot rated I/75 and C/75, and you should strongly consider additional ratings like Puncture Resistance (PR) or Metatarsal (Mt).

- If your primary focus is electrical work: The Electrical Hazard (EH) rating is non-negotiable, in addition to the mandatory I/75 and C/75 toe protection.

- If your primary focus is logistics or light manufacturing: The core I/75 and C/75 protection is essential, with slip resistance often being a critical factor not covered by these core ratings.

- If your primary focus is demolition or waste management: A Puncture Resistant (PR) rating is vital to protect the soles of your feet from nails, rebar, and other sharp debris.

Understanding these standards empowers you to make an informed decision that actively protects you from harm.

Summary Table:

| Standard | Region | Key Requirement |

|---|---|---|

| ASTM F2413 | USA | Impact (I/75) & Compression (C/75) resistance |

| OSHA 1910.136 | USA | Mandates use of ASTM-compliant footwear |

| EN ISO 20345 | Europe | 200-joule toe cap impact resistance |

| Common Ratings | --- | --- |

| EH | Electrical Hazard protection | |

| Mt/75 | Metatarsal protection | |

| PR | Puncture Resistant sole |

Ensure your workforce is equipped with certified, compliant safety footwear.

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM F2413 and EN ISO 20345 compliant safety boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear, from basic steel toe to specialized EH and metatarsal guard boots, ensuring you get the right protection for your specific industry hazards.

Contact us today for a consultation on your safety footwear needs and discover how we can deliver quality, compliance, and value.

Visual Guide

Related Products

- Premium Waterproof Nubuck Safety Boots for Wholesale

- Premium Grain Leather Safety Boots for Bulk Supply

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- What core protection functions do industrial-grade Safety Shoes provide during drilling and blasting in a quarry?

- How do safety shoes and ergonomic measures protect workers? Prevent Musculoskeletal Injuries in Waste Management

- What advantages do wearable pressure insole systems offer over waist-mounted sensors for fall risk assessment? Discover Precision Safety

- What is the necessity of professional safety shoes in hospital nursing? Protect Your Health with Ergonomic Footwear

- Are there any limitations to oil resistant safety boots? Key Risks and How to Mitigate Them

- What are the benefits of using waterproof safety shoes during mining road maintenance and dust suppression activities?

- What standard must protective footwear comply with? Meet OSHA & ASTM F2413 Requirements

- What are some alternatives to firefighter boots? Find the Right Footwear for Non-Fireground Duties