Beyond the basics, a truly safe worksite relies on a comprehensive system of Personal Protective Equipment (PPE) designed to shield workers from specific, identifiable hazards. This includes gear for head protection against falling objects, eye and face protection from debris, hearing protection from loud machinery, respiratory equipment to prevent inhalation of toxins, and specialized suits or vests for high-visibility and environmental defense.

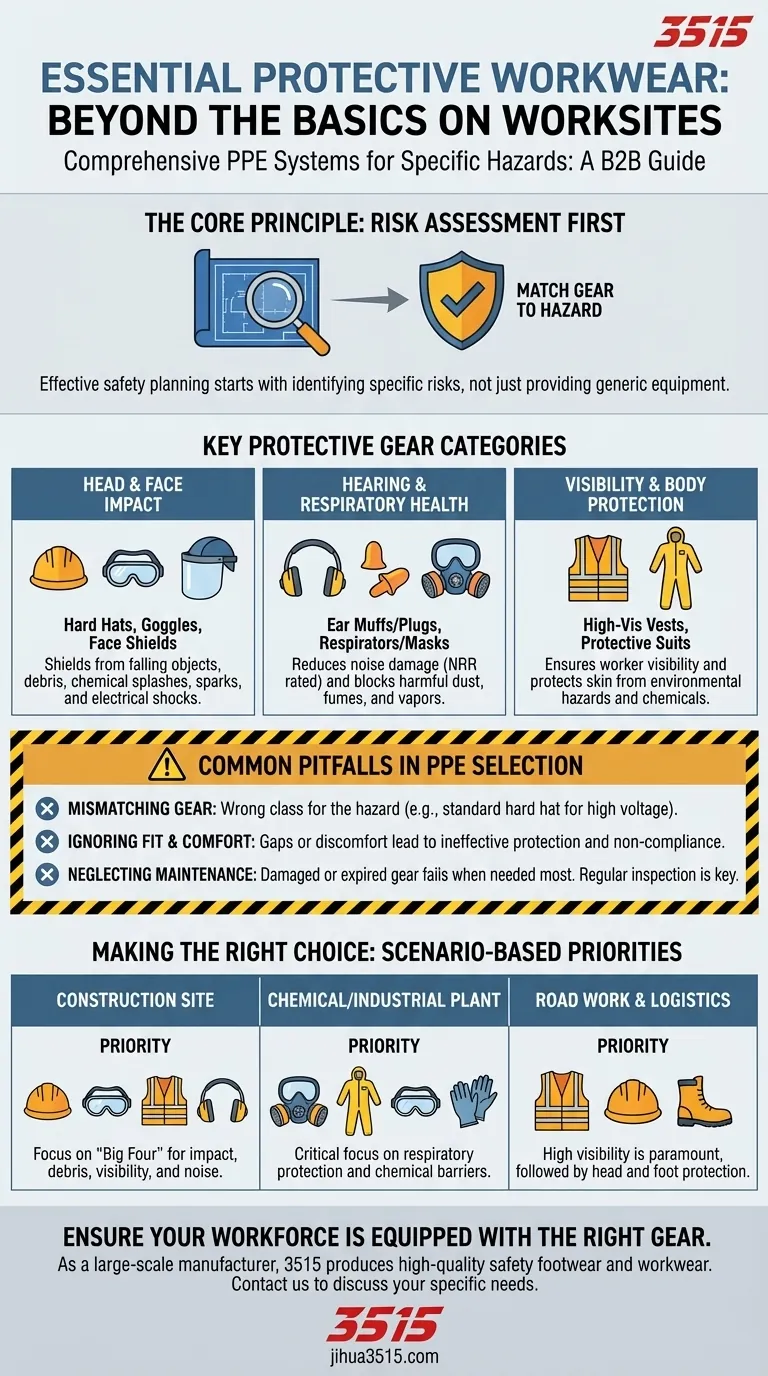

The core principle of protective workwear is not just to have it, but to match the right piece of equipment to the specific hazard. Effective safety planning involves a thorough risk assessment of the environment to determine exactly what protection is required.

Protecting the Head and Face from Impact

Your head and face are critically vulnerable to a range of worksite hazards, from direct impact to flying particles. The right equipment is your first line of defense.

Hard Hats and Safety Helmets

A hard hat is the most fundamental piece of head protection. Its primary purpose is to shield the head from falling objects, collisions with fixed objects, and electrical shocks.

Different classes of hard hats are rated for different levels of impact and electrical resistance, making it crucial to select one appropriate for the job's specific risks.

Goggles and Face Shields

Safety goggles are essential for protecting the eyes from dust, airborne debris, and chemical splashes. They form a protective seal around the eyes, offering more complete coverage than standard safety glasses.

For tasks like welding, grinding, or handling potent chemicals, a face shield provides a broader barrier. It protects the entire face from sparks, splashes, or intense heat, and is typically worn in conjunction with safety goggles.

Guarding Hearing and Respiratory Health

Some of the most serious worksite dangers are the ones you can't see or immediately feel, like damaging noise levels and airborne contaminants.

Ear Muffs and Earplugs

Continuous exposure to loud machinery causes irreversible hearing damage. Earplugs and ear muffs are designed to reduce noise exposure to a safe level.

The choice between them often depends on the noise level, duration of exposure, and user comfort. Both are rated with a Noise Reduction Rating (NRR) to help you select the appropriate level of protection.

Face Masks and Filters

Worksites can generate dust, fumes, vapors, and other toxic substances that are hazardous when inhaled. Face masks and respirators with specialized filters are critical for protecting your lungs.

The type of filter required depends entirely on the specific contaminant you need to block, ranging from simple particulate masks to complex cartridge respirators for chemical vapors.

Ensuring Visibility and Body Protection

Protecting the body from environmental hazards and ensuring workers are seen by equipment operators are final, crucial layers of safety.

Reflective and High-Visibility Vests

In any environment with moving vehicles or equipment, especially in low-light conditions, visibility is paramount. Reflective vests make workers stand out, dramatically reducing the risk of struck-by accidents.

Protective Suits

For handling hazardous materials, working in extreme weather, or dealing with chemical spills, a full protective suit may be necessary. These suits are designed to shield the skin and body from chemical burns, contamination, or severe temperatures.

Common Pitfalls in PPE Selection

Simply providing equipment is not enough. The effectiveness of any PPE program hinges on avoiding common mistakes that undermine its protective value.

Mismatching the Gear to the Hazard

The most common failure is choosing the wrong class of equipment. A standard hard hat offers no protection from high-voltage electricity, and a basic dust mask is useless against chemical fumes. A risk assessment must identify the specific hazard.

Ignoring Proper Fit and Comfort

If PPE doesn't fit correctly, it cannot provide adequate protection. Goggles that leave gaps, respirators that don't seal, or earplugs that are too loose are all ineffective. Furthermore, uncomfortable gear is less likely to be worn consistently.

Neglecting Inspection and Maintenance

All PPE has a limited lifespan and is subject to wear and tear. A cracked hard hat, a scratched face shield, or a clogged respirator filter can fail when needed most. Regular inspection and replacement are non-negotiable.

Making the Right Choice for Your Goal

Selecting the right combination of PPE depends entirely on the environment and the tasks being performed.

- If your primary focus is a general construction site: Prioritize the "big four"—a proper hard hat for impact, safety goggles for debris, a high-visibility vest, and hearing protection for use around loud equipment.

- If your primary focus is a chemical or industrial plant: Respiratory protection becomes critical, requiring careful selection of masks and filters matched to the specific airborne contaminants present.

- If your primary focus is road work or logistics: High-visibility vests are the most important piece of equipment, followed by head protection and safety-toed boots.

Ultimately, a safe worksite is the result of a deliberate culture that correctly identifies risks and empowers every worker with the right tools to mitigate them.

Summary Table:

| Body Part / Hazard | Essential Protective Gear | Key Function |

|---|---|---|

| Head & Impact | Hard Hats / Safety Helmets | Protects from falling objects, impacts, and electrical shocks. |

| Eyes & Face | Safety Goggles / Face Shields | Shields from debris, chemical splashes, sparks, and heat. |

| Hearing | Earplugs / Ear Muffs | Reduces noise exposure to prevent hearing damage (rated by NRR). |

| Lungs & Respiration | Face Masks / Respirators with Filters | Blocks inhalation of dust, fumes, vapors, and toxic substances. |

| Visibility & Body | High-Visibility Vests / Protective Suits | Ensures worker visibility and protects from environmental hazards. |

Ensure your workforce is equipped with the right protective gear. As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality safety footwear and workwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and specialized footwear designed to meet rigorous worksite demands.

Contact us today to discuss your specific needs and benefit from our expertise in durable, reliable protective solutions.

Visual Guide

Related Products

- Premium Waterproof Nubuck Safety Boots for Wholesale

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

People Also Ask

- What is the purpose of safety toe boots? Ultimate Protection for Your Work Environment

- What are the signs that safety toe boots are worn out and need replacement? Ensure Your Workplace Safety

- How can foot scanners help in selecting the right safety toe boots? Get a Perfect Fit with 3D Data

- What standards must safety toe boots meet? Ensure Your Footwear Meets ASTM F2413

- How does routine boot maintenance benefit workplace safety? Proactive PPE Protection for Your Workforce