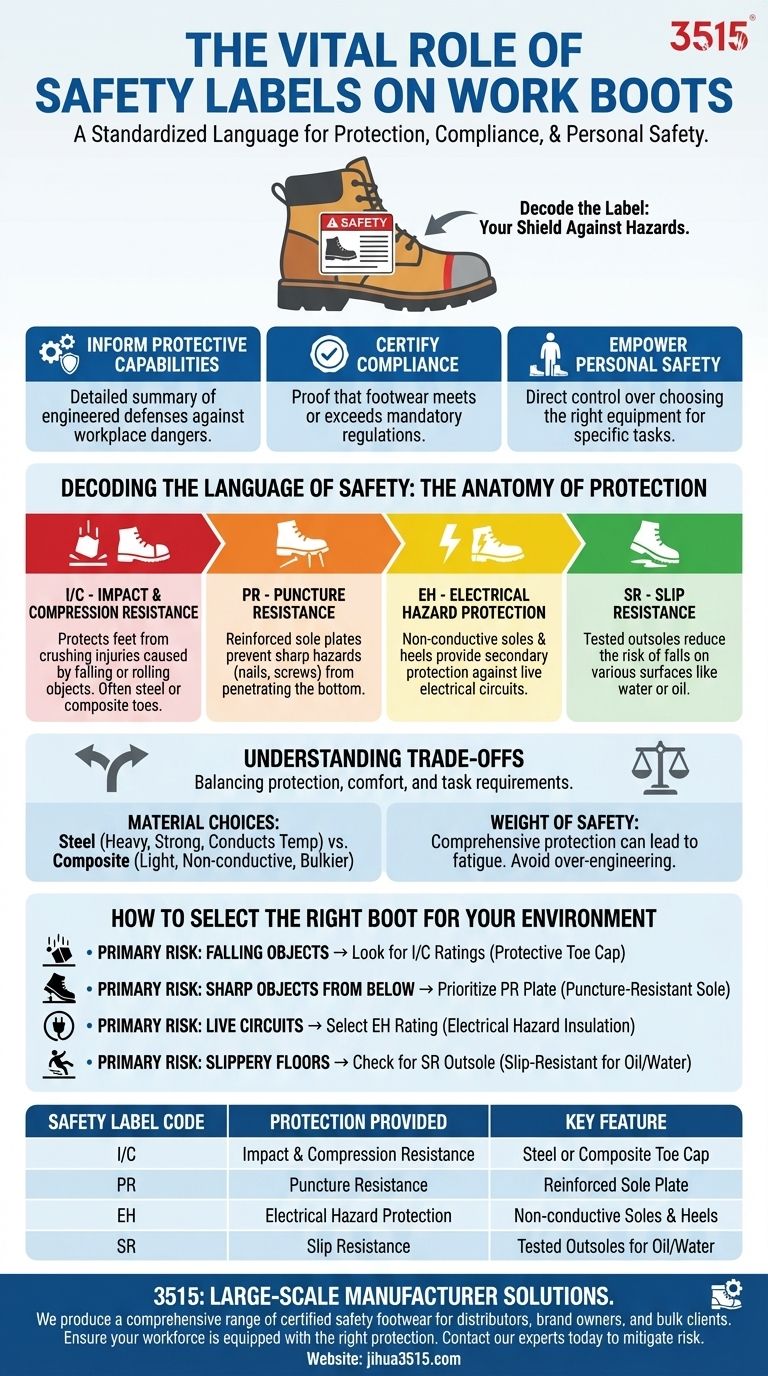

At its core, a safety label on a work boot is a standardized language communicating its specific protective capabilities. These labels serve three primary purposes: they inform the wearer about the boot's engineered defenses against workplace hazards, they certify compliance with mandatory safety regulations, and they empower you to actively ensure your own personal safety by choosing the right equipment for the job.

Understanding these labels transforms your perspective from simply buying footwear to selecting a critical piece of Personal Protective Equipment (PPE) that is precisely engineered for specific, known risks.

Decoding the Language of Safety

A safety label is not a marketing feature; it is a technical specification. It provides a clear, concise summary of how the boot is designed to protect you from the physical dangers present in your work environment.

The Anatomy of Protection

Each code or symbol on a safety label corresponds to a specific protective feature built into the boot's construction. These are the most common protections you will find.

- Impact & Compression Resistance: This is the most recognized feature, often provided by steel toes or lighter-weight composite toes. They are designed to protect your feet from crushing injuries caused by heavy falling or rolling objects.

- Puncture Resistance: Many job sites have sharp hazards like nails, screws, or rebar on the ground. Boots with reinforced sole plates prevent these objects from penetrating the bottom of the boot and causing serious injury.

- Electrical Hazard (EH) Protection: Specialized EH-rated footwear is constructed with non-conductive, shock-resistant soles and heels. This feature provides a secondary source of protection against accidental contact with live electrical circuits.

- Slip Resistance: The boot's outsole is a critical safety component. Labels can indicate that a boot has been tested for slip resistance on various surfaces, such as those covered in water or oil, reducing the risk of falls.

The Role of Regulatory Compliance

In many industries, government bodies and safety organizations mandate specific levels of foot protection. These regulations are not suggestions; they are legal requirements for employers.

A safety label serves as proof that the footwear meets or exceeds these established standards. For both an employer and an employee, using properly labeled boots is a key part of maintaining a compliant and safe workplace, preventing fines and liability.

Understanding the Trade-offs

Selecting the right safety boot involves balancing protection with the practical demands of your job. No single boot is perfect for every task, and understanding the inherent trade-offs is crucial.

Material Choices Matter

The choice between a steel toe and a composite toe is a classic example. Steel offers maximum protection and is often less bulky, but it is heavier and conducts temperature. Composite materials are lighter and don't conduct heat or cold, but may be slightly bulkier to achieve the same safety rating.

The Weight of Safety

More protective features often mean a heavier, more rigid boot. While a boot with a steel toe, puncture plate, and metatarsal guard offers comprehensive protection, its weight can lead to fatigue over a long workday. This can be a safety issue in itself.

Mismatched Protection

A common pitfall is choosing a boot that is over-engineered for your specific environment. A heavy-duty puncture-resistant boot designed for a construction site may be cumbersome and unnecessary for an electrician who primarily needs an EH rating and flexibility.

How to Select the Right Boot for Your Environment

Your choice should always be driven by a clear assessment of the primary risks you face daily.

- If your primary risk is falling objects: Look for labels specifying impact (I) and compression (C) ratings, which confirm the strength of the protective toe cap.

- If your primary risk is sharp objects from below: Prioritize boots with a labeled puncture-resistant (PR) plate built into the sole.

- If your primary risk is contact with live circuits: You must select footwear clearly marked with an Electrical Hazard (EH) rating for proper insulation.

- If your primary risk is slippery floors: Check for labels indicating a slip-resistant (SR) outsole designed for the specific conditions you work in, such as oil or water.

By learning to read the label, you take direct control over your personal safety in any work environment.

Summary Table:

| Safety Label Code | Protection Provided | Key Feature |

|---|---|---|

| I/C | Impact & Compression Resistance | Steel or Composite Toe Cap |

| PR | Puncture Resistance | Reinforced Sole Plate |

| EH | Electrical Hazard Protection | Non-conductive Soles & Heels |

| SR | Slip Resistance | Tested Outsoles for Oil/Water |

Ensure Your Workforce is Equipped with the Right Protection

Choosing the correct safety footwear is critical for compliance and on-the-job safety. As a large-scale manufacturer, 3515 produces a comprehensive range of certified work boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety footwear, from steel-toe boots to EH-rated and slip-resistant models, ensuring you get precisely what your team needs.

Let us help you mitigate risk and enhance workplace safety.

Contact our experts today to discuss your specific requirements and discover the right safety solutions for your business.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- How do safety features in work boots contribute to overall comfort and safety? Unlock the Secret to All-Day Protection

- Why are waterproof work boots important and who should use them? Essential Foot Protection for Outdoor & Wet Work

- What are the temperature ratings and recommended uses for 400g insulated boots? Your Guide to Winter Warmth

- Why is safety the top priority when selecting oilfield work boots? Essential Protection for High-Risk Environments

- What does the 'EH' in ASTM F2413-18 M/I/C EH PR MT stand for? Decode Safety Boot Labels for Maximum Protection

- What organization provides safety standards for work boots? Meet ASTM International, the Key to OSHA Compliance

- What are the consequences of wearing ill-fitting work boots? Protect Your Health and Safety

- What safety advantages do insulated boots offer beyond warmth? Dielectric Protection & Superior Grip