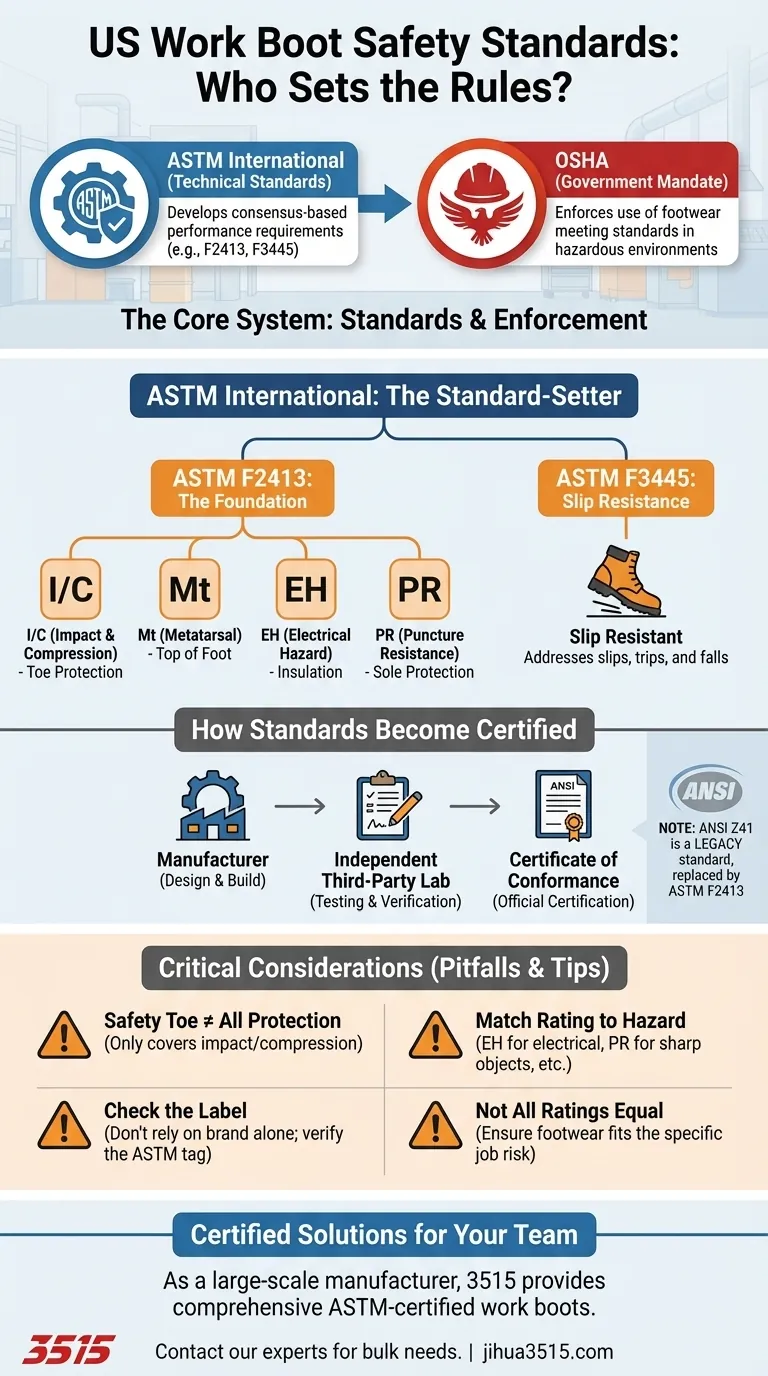

In the United States, the primary organization that provides the technical safety standards for work boots is ASTM International, formerly known as the American Society for Testing and Materials. This organization develops the consensus-based performance requirements that footwear must meet to be considered protective. Government bodies like the Occupational Safety and Health Administration (OSHA) then often require compliance with these ASTM standards for workplace safety.

The core system for ensuring work boot safety relies on two key entities: ASTM International, which develops the technical testing standards, and OSHA, which mandates and enforces the use of protective footwear that meets those standards in hazardous environments.

The Key Player: ASTM International

ASTM International creates the foundational documents that define what "safe" means for footwear. These are not laws, but highly respected technical standards developed by industry experts.

What is ASTM?

ASTM is a global organization that develops and publishes voluntary consensus technical standards for a wide range of materials, products, systems, and services. For work boots, they define the specific tests and performance results required for a boot to earn a safety rating.

The Core Standard: ASTM F2413

This is the cornerstone specification for protective footwear. It establishes the minimum requirements for performance in several critical areas, including:

- Impact (I) and Compression (C) Resistance: Protects the toes from falling objects and crushing forces.

- Metatarsal (Mt) Protection: Guards the top of the foot from impact.

- Electrical Hazard (EH) Resistance: Insulates the wearer from open electrical circuits.

- Puncture Resistance (PR): Protects the sole of the foot from sharp objects like nails.

The Slip Resistance Standard: ASTM F3445

Because slips, trips, and falls are among the most common workplace injuries, a separate standard was developed to address this specific hazard. ASTM F3445-21 outlines the performance requirements for footwear sole slip resistance, providing a more reliable measure than older methods.

How Standards Become Requirements

A standard written by ASTM only becomes a rule when an authority like a government agency or an employer requires it. This is where the system ensures widespread protection.

The Role of OSHA

The Occupational Safety and Health Administration (OSHA) is the U.S. government agency responsible for ensuring safe and healthful working conditions. OSHA regulations mandate that employers provide, and employees use, protective footwear in workplaces where there is a danger of foot injuries. While OSHA sets the rule, it points to standards like ASTM F2413 as the benchmark for acceptable footwear.

Independent Third-Party Testing

A manufacturer cannot simply claim their boots meet ASTM standards. To be officially certified, the footwear must be tested by an independent, third-party laboratory. This lab issues a Certificate of Conformance that verifies the product meets the specific performance criteria outlined in the standard, ensuring unbiased and reliable safety ratings.

The Legacy of ANSI

You may occasionally see references to the American National Standards Institute (ANSI) regarding safety boots. The previous standard was ANSI Z41, but it was withdrawn and replaced by the ASTM F2413 standard. Today, ASTM is the current and relevant standard-developing organization for protective footwear in the U.S.

Common Pitfalls to Avoid

Understanding the standards is crucial, but misinterpreting them can lead to a false sense of security.

"Safety Toe" is Not Enough

A boot labeled "safety toe" only guarantees it has passed the impact and compression tests for the toe area. It does not mean it is puncture-resistant or protects against electrical hazards unless it is explicitly rated for those features. Always check the specific ASTM labels inside the boot.

Not All Ratings Are Created Equal

Work boots are tested and rated for specific hazards. A boot that is excellent for a construction site with puncture risks may be entirely wrong for an electrician who needs EH-rated protection. The hazard dictates the necessary standard.

Relying on Brand Alone

While reputable brands are more likely to comply with standards, the only true confirmation is the official ASTM certification label. This label breaks down exactly which protections the boot offers.

Making the Right Choice for Your Hazard

Use the specific ASTM ratings to match your footwear to the risks of your job.

- If your primary focus is protection from falling objects: Look for boots with an ASTM F2413 I/75 C/75 rating, which is the highest standard for impact and compression.

- If your primary focus is working around live circuits: You must select boots with an EH (Electrical Hazard) rating to ensure they provide the necessary insulation.

- If your primary focus is preventing slips on wet or oily surfaces: Prioritize boots that are explicitly certified to the ASTM F3445-21 slip resistance standard.

- If your primary focus is protection from nails or sharp debris: Ensure the boot is clearly marked with the PR (Puncture Resistant) rating.

Understanding these standards empowers you to look beyond marketing and verify the specific protections your footwear provides.

Summary Table:

| Standard | Key Focus | Protection Provided |

|---|---|---|

| ASTM F2413 | Foundational Safety | Impact/Compression (I/C), Metatarsal (Mt), Electrical Hazard (EH), Puncture (PR) |

| ASTM F3445 | Slip Resistance | Reduces slips, trips, and falls on wet or oily surfaces |

| ANSI Z41 | Legacy Standard | Withdrawn and replaced by ASTM F2413 |

Need Certified Safety Footwear for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified work boots and shoes for distributors, brand owners, and bulk clients. We ensure every pair meets the precise requirements of standards like ASTM F2413 and F3445, providing the verified protection your workforce needs.

Let us help you select the right footwear for your specific hazards. Contact our experts today to discuss your requirements and get a quote.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- What materials are used in Chemical Resistant boots for additional protection? Choose the Right Defense for Your Workplace

- What industries benefit from heavy duty work boots? Essential PPE for High-Risk Environments

- What are the requirements for compression resistance in safety toe boots? Ensure OSHA & ASTM F2413 Compliance

- What are the characteristics of a good outsole for work boots? Find the Right Traction & Durability

- What is the origin of engineer boots? Born in the 1930s for Industrial Workers

- Why is conditioning or oiling leather work boots important? Prevent Cracking & Extend Boot Life

- What are the key requirements for wildland firefighting boots? NFPA-Certified Safety & Durability

- Which material is recommended for work boots in cold, wet environments? Neoprene for Superior Warmth