When fitting engineer boots, the most critical factors are a snug fit over the instep and accepting some initial heel slippage. Because they are laceless, the boot must hold your foot securely across the top; this is non-negotiable. While the leather will stretch slightly in width and mold to your foot over time, it will never stretch in length, so ensure your toes have adequate room from the start.

The core challenge of fitting an engineer boot is finding a size that secures your foot without laces. Success hinges on getting the instep fit correct, as this is what prevents your foot from sliding, while understanding that initial heel slip is a normal part of the break-in process for stiff, well-made footwear.

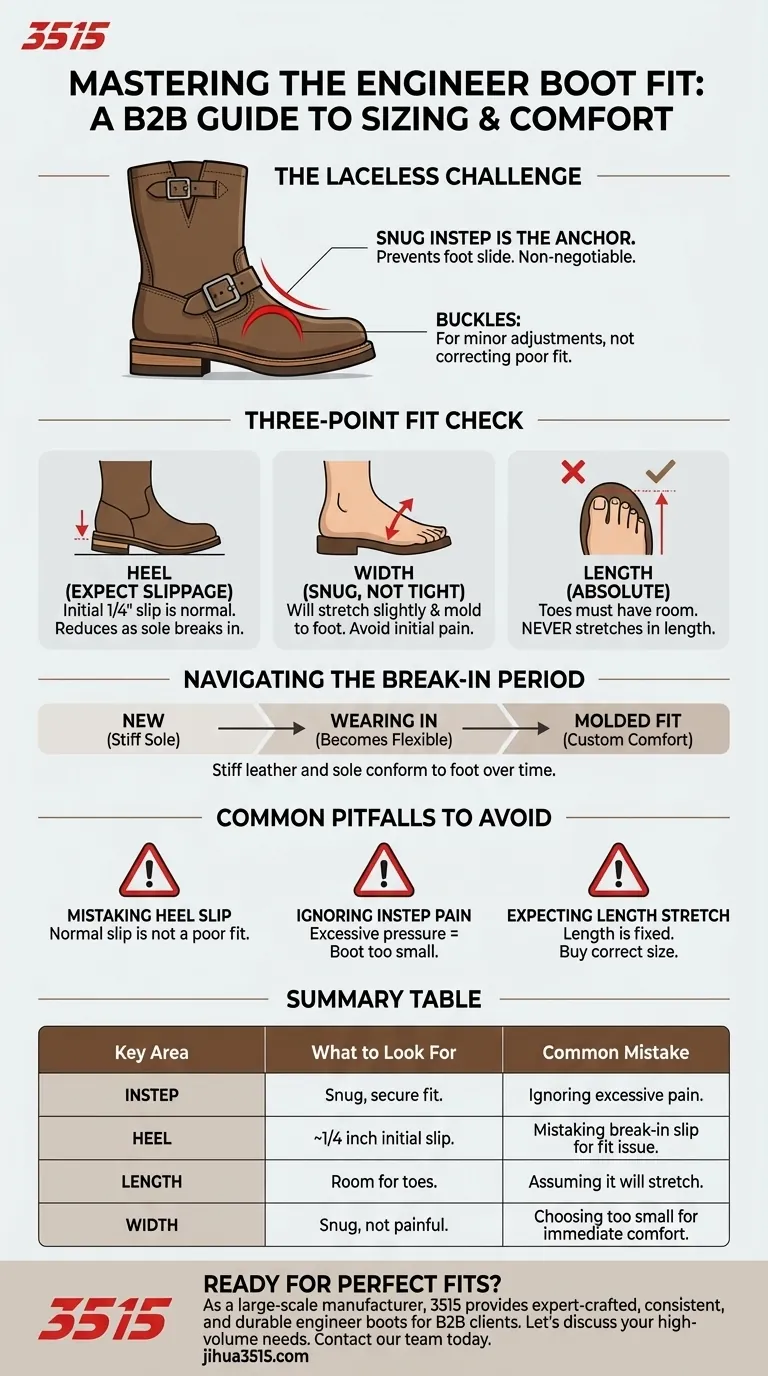

The Unique Challenge of a Laceless Fit

Engineer boots are a tall, laceless style defined by their durable construction and adjustable buckles. This unique design requires a different approach to fitting compared to standard laced boots.

The Instep is Your Anchor

Without laces to tighten the boot, the fit across the instep (the arched top part of your foot) becomes the single most important factor.

A proper fit means the boot should feel snug and secure over your instep. This is what holds your foot in place and prevents it from sliding forward.

The True Purpose of the Buckles

The buckles at the ankle and top of the shaft are for minor adjustments, not for correcting a poor fit.

They help customize the fit around your ankle and calf, but they cannot compensate for a boot that is too loose or too tight over the instep.

Heel, Width, and Length: The Three-Point Check

When you try on the boots, assess three key areas. Your heel should have some initial slippage, typically a quarter-inch or so. This is normal and will lessen as the stiff sole breaks in.

The width should be snug but not painfully tight. Full-grain leather will stretch and mold slightly to the width of your foot.

Finally, the length is absolute. Your toes should not be touching the end of the boot. Unlike width, the length will not stretch.

Navigating the Break-In Period

Quality engineer boots are built with durable full-grain leather and often a Goodyear welt construction, meaning they require a break-in period to conform to your foot.

Understanding Normal Heel Slippage

Initial heel slip occurs because the new, stiff leather sole doesn't flex easily with your foot's movement.

As you wear the boots, the sole will become more flexible and a pocket will form for your heel, drastically reducing or eliminating this slippage. Excessive, sloppy slippage, however, may indicate the boot is too large.

How the Boot Molds to You

The break-in process is your foot making an impression on the leather. The leather upper will soften and shape around your foot's unique contours.

The cork or leather footbed will also compress and mold to the bottom of your foot, creating a custom and comfortable fit over time.

Common Pitfalls in Sizing Engineer Boots

Avoiding a few common mistakes is crucial for finding the right fit and preventing a costly error.

Mistaking Heel Slip for a Poor Fit

The most common error is returning a pair of boots that are the correct size because of initial heel slippage. Remember that this is a temporary and expected part of the break-in process for high-quality, stiff boots.

Ignoring Instep Pressure

Conversely, do not ignore excessive pressure or pain on your instep. If getting the boot on is a major struggle or the top of your foot feels painfully compressed, the boot is too small in volume for your foot, regardless of its length.

Assuming They Will Stretch in Length

Never buy engineer boots with the expectation that they will get longer. While the width will give a little, the length is fixed. Ensure you have comfortable room for your toes from day one.

Making the Right Choice for Your Foot

Your approach to sizing depends on your ability to try the boots on and your familiarity with the specific brand's sizing.

- If you are a first-time buyer: Prioritize trying the boots on in a store. Feeling the instep pressure and the amount of heel slip is the most reliable way to ensure a proper fit.

- If you are buying online: Carefully measure your foot and consult the manufacturer's specific sizing guide. Pay close attention to reviews that mention if a boot runs large, small, or true to size.

- If your primary focus is a perfect fit: Be prepared for the break-in period. Wear thick socks initially and wear the boots for short periods around the house to help the leather mold to your foot without causing excessive discomfort.

Ultimately, a well-fitted engineer boot becomes an extension of your foot, offering unmatched durability and comfort once broken in.

Summary Table:

| Key Fitting Area | What to Look For | Common Mistake to Avoid |

|---|---|---|

| Instep | Snug, secure fit that holds the foot in place. | Ignoring excessive pressure or pain. |

| Heel | Some initial slippage (about 1/4 inch) is normal. | Mistaking normal break-in slip for a poor fit. |

| Length | Toes should not touch the end of the boot. | Assuming the boot will stretch in length. |

| Width | Snug but not painfully tight; will stretch slightly. | Choosing a size too small for immediate comfort. |

Ready for Engineer Boots That Fit Perfectly?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of high-quality shoes and boots, including engineer boots built for superior comfort and longevity.

We help you provide your customers with:

- Expertly crafted boots designed with the key fitting principles in mind.

- Consistent, reliable sizing across large production runs.

- Durable materials that mold to the foot for a custom fit.

Let's discuss your footwear needs. Contact our team today to explore how we can support your business with high-volume, quality manufacturing.

Visual Guide

Related Products

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What is the recommended method for cleaning boot leather? A Step-by-Step Guide to Preserve Your Boots

- What makes engineer boots suitable for motorcycle riding? Classic Style Meets Core Protection

- What materials are used in comfortable Western-style work boots? Unlock All-Day Comfort & Durability

- What are the key features of structural firefighting boots? Engineered for Ultimate Protection & Performance

- Why should extreme heat be avoided when drying work boots? Protect Your Investment & Safety

- What type of sole is used in wildland firefighter boots and why? Essential Heat-Resistant Lug Soles

- What structural features are important in Wellington work boots? Ensure Slip-On Safety and Support

- What are the features of zip-up work boots? Unlock Speed, Safety, and Comfort