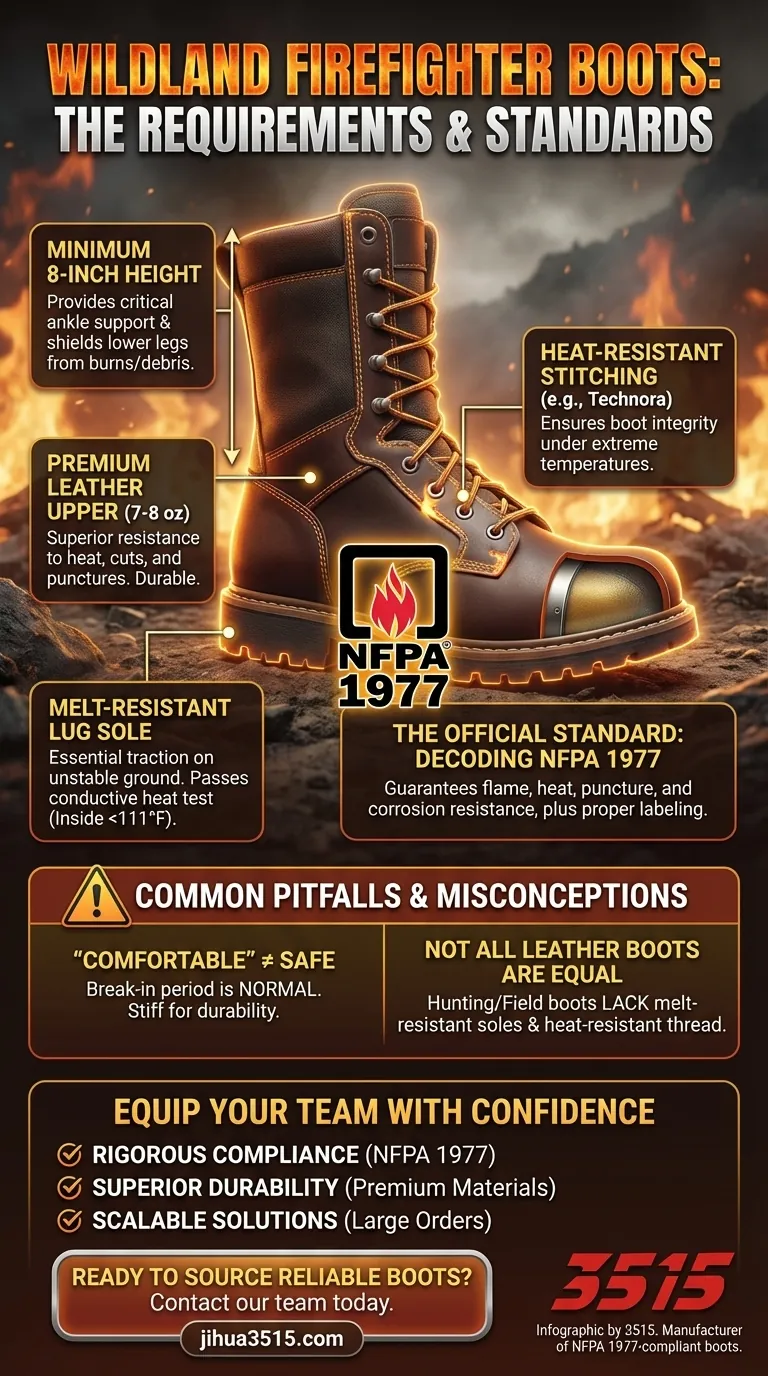

To be considered a wildland firefighter boot, a boot must meet a strict set of requirements designed for extreme environments. At a minimum, it must be a lace-up leather work boot at least 8 inches tall, measured from the bottom of the heel. Crucially, it must feature a lug-style sole made from melt-resistant material to provide traction and protection from ground heat.

The core requirements for wildland fire boots are not just a checklist; they form an essential system of safety. Each specification—from the 8-inch height to the heat-resistant stitching—is a direct response to the specific, life-threatening hazards encountered on the fireline.

Why These Boot Standards Are Non-Negotiable

A wildland fire environment is one of the most demanding workplaces on earth. Firefighters navigate steep, unstable terrain covered in ash and hidden debris, all while being exposed to extreme radiant and conductive heat. The right boot is not just equipment; it's a critical piece of personal protective equipment (PPE).

The 8-Inch Height Rule: Stability and Shielding

The minimum 8-inch height is mandated for two primary reasons. First, it provides essential ankle support, helping to prevent sprains and fractures when walking on uneven ground for long hours.

Second, the height acts as a shield, protecting the lower leg from burns, abrasions, and the intrusion of hot embers and sharp debris.

Material and Construction: Your First Line of Defense

Wildland boots are required to have an exterior made of durable, premium leather, typically seven or eight ounces thick. This material provides excellent resistance to heat, cuts, and punctures.

All stitching must use heat-resistant thread, like Technora. This ensures the boot doesn’t fall apart when exposed to high temperatures, a failure point for standard work boots.

The Sole: Your Connection to Unstable Ground

The sole is perhaps the most specialized component. It must be made of a melt-resistant rubber compound and feature a deep, aggressive lug pattern.

This design provides critical traction on loose soil, rock, and ash. The sole itself must also pass a conductive heat test, ensuring the inside of the boot does not exceed 111°F when the exterior is exposed to heat, protecting the foot from ground fire.

The Official Standard: Decoding NFPA 1977

The National Fire Protection Association (NFPA) sets the definitive standard for wildland firefighting protective clothing and equipment, including boots. This is NFPA 1977.

Key NFPA 1977 Requirements

- Flame Resistance: The boot cannot melt, drip, or burn through after a short, direct flame exposure.

- Heat Resistance: The boot must not delaminate or have its components melt when exposed to high ambient heat.

- Puncture & Cut Resistance: The upper portion of the boot must demonstrate a high level of resistance to penetration from sharp objects.

- Corrosion Resistance: All metal parts, such as eyelets and hooks, must resist corrosion and be securely attached.

- Labeling: A permanent interior label must clearly state that the boot complies with NFPA 1977 standards.

Common Pitfalls and Misconceptions

Choosing the right boot involves understanding the necessary trade-offs and avoiding dangerous assumptions. Safety and function must always come before comfort or aesthetics.

"Comfortable" Does Not Equal "Safe"

A new wildland boot should not feel overly comfortable or flexible right out of the box. The stiffness and substantial feel come from the heavy-duty leather and robust construction required for durability and protection.

A significant break-in period is normal and necessary. Firefighters should always acquire new boots well before they are needed to allow time for this process.

Not All Leather Boots Are Created Equal

It is critical to distinguish certified wildland boots from other types of high-ankled leather boots, such as hunting or riding "field boots."

While they may look similar, these other boots lack the melt-resistant soles, heat-resistant thread, and specific material testing required by NFPA 1977. Wearing them on a fireline is a significant safety risk.

Making the Right Choice for Your Role

Selecting a boot is about matching certified protection to your specific needs. Always verify NFPA 1977 compliance as the first step.

- If you are a new firefighter: Prioritize a certified boot with a proper, snug fit and purchase it well in advance to allow for a thorough break-in period.

- If you are purchasing for a crew: Verify NFPA 1977 certification for every model and focus on durability and sole construction as the primary criteria.

- If you are operating in unique terrain: Be aware of regional exceptions, such as Alaska's exemption from the lug sole requirement, but never compromise on the core heat and flame resistance standards.

Ultimately, your boots are the foundation that allows you to work safely and effectively in a hazardous environment.

Summary Table:

| Key Requirement | Purpose & Benefit |

|---|---|

| Minimum 8-Inch Height | Provides critical ankle support and shields lower legs from burns and debris. |

| Premium Leather Upper | Offers superior resistance to heat, cuts, and punctures for long-lasting durability. |

| Melt-Resistant Lug Sole | Ensures essential traction on unstable ground and protects feet from conductive heat. |

| Heat-Resistant Stitching | Prevents boot failure by ensuring seams hold up under extreme temperatures. |

| NFPA 1977 Certification | Guarantees the boot meets all official standards for flame, heat, and puncture resistance. |

Equip Your Team with Confidence

As a large-scale manufacturer, 3515 produces NFPA 1977-compliant wildland fire boots built for the extreme demands of the fireline. We provide durable, certified footwear for distributors, brand owners, and bulk clients who prioritize the safety of their crews.

Our production capabilities ensure:

- Rigorous Compliance: Every boot meets or exceeds NFPA 1977 standards.

- Superior Durability: We use premium materials designed to withstand the harshest conditions.

- Scalable Solutions: We support large orders with consistent quality and reliable delivery.

Ready to source reliable wildland fire boots? Contact our team today to discuss your specific needs and receive a quote.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Wholesale Lightweight Tactical Boots Custom Manufacturer for Desert & Combat Use

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

People Also Ask

- What is the purpose of steel toe caps in firefighter boots? Maximum Impact & Crush Protection

- What is the core protective function of steel-toe safety shoes in preventing lower limb injuries caused by chainsaws?

- What safety standards should oilfield work boots meet? Ensure OSHA & ASTM F2413 Compliance

- How do work boots provide impact and compression resistance? The Science Behind the Protective Toe Cap

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear