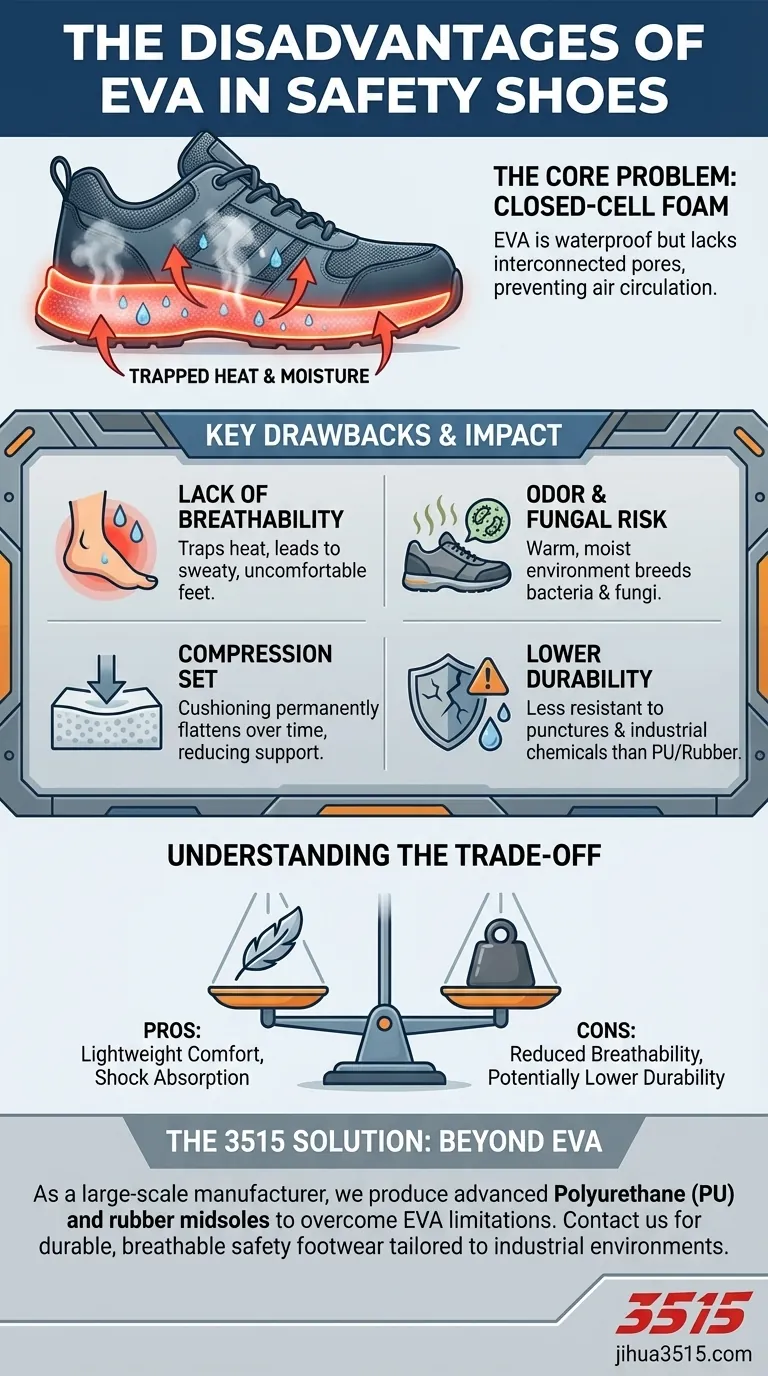

At its core, the primary disadvantage of using EVA foam in safety shoes is its lack of breathability. Because EVA is a closed-cell foam and inherently waterproof, it does not allow air to circulate, which can lead to excessive moisture, heat buildup, and unpleasant odors inside the shoe during long periods of wear.

The decision to choose a safety shoe with an EVA midsole is a direct trade-off: you gain significant lightweight comfort and shock absorption at the cost of reduced breathability and potentially lower durability under harsh industrial conditions.

The Core Problem: Trapped Heat and Moisture

Ethylene-vinyl acetate (EVA) is prized for being exceptionally lightweight and providing excellent cushioning. However, the very properties that make it a great shock absorber also create its biggest drawback in a work environment.

Lack of Breathability

EVA is a closed-cell foam. This structure means the gas bubbles inside the material are not interconnected.

This design is what makes EVA waterproof and a great insulator, but it also completely prevents air exchange.

Consequently, the heat and sweat generated by your feet have nowhere to escape, creating a hot, humid environment inside the shoe.

Potential for Odor and Fungal Growth

The warm, moist environment created by non-breathable EVA is an ideal breeding ground for bacteria and fungi.

This can lead to persistent, unpleasant odors that are difficult to remove from the shoe.

More critically, it can increase the risk of foot health issues like athlete's foot over time, especially for individuals prone to sweating.

Understanding the Trade-offs

Choosing a safety shoe involves balancing competing priorities. While EVA offers clear benefits, its weaknesses are significant in certain contexts.

Durability and Compression Set

EVA's softness, while comfortable, can also be a liability. Over time and under the repeated stress of walking and standing, EVA midsoles can suffer from "compression set."

This means the foam permanently flattens and loses its ability to bounce back, reducing its cushioning and supportive properties.

In demanding industrial environments with heavy loads or long hours on hard surfaces, an EVA midsole may wear out faster than one made from more resilient materials like Polyurethane (PU).

Puncture and Chemical Resistance

While the outsole of a safety shoe provides the primary barrier, the material of the midsole also matters.

EVA is softer and less dense than materials like rubber or PU. This makes it more susceptible to being compromised by sharp objects that might penetrate the outsole.

Additionally, its resistance to certain industrial oils and chemicals may be lower than other more robust compounds, potentially leading to degradation of the midsole over time.

Making the Right Choice for Your Goal

The suitability of EVA in your safety footwear depends entirely on your work environment and daily tasks.

- If your primary focus is light-duty work and maximum comfort: An EVA midsole is an excellent choice for roles with lots of walking but minimal exposure to harsh conditions, such as in logistics, warehousing, or light assembly.

- If your primary focus is durability in a harsh environment: You should consider safety shoes with Polyurethane (PU) or rubber midsoles, as they offer superior resistance to compression, chemicals, and abrasion.

- If your primary focus is managing foot heat and moisture: Prioritize shoes with breathable upper materials and moisture-wicking linings, and be aware that an EVA midsole will contribute to heat retention regardless of other features.

Ultimately, understanding the material properties of your footwear empowers you to select the right tool for the job.

Summary Table:

| Disadvantage | Impact on the Wearer |

|---|---|

| Lack of Breathability | Traps heat and moisture, leading to sweaty, uncomfortable feet. |

| Potential for Odor | Creates a breeding ground for bacteria and fungi. |

| Compression Set | Cushioning permanently flattens over time, reducing support. |

| Lower Durability | Less resistant to harsh conditions, chemicals, and punctures compared to PU or rubber. |

Don't let the wrong material compromise safety and comfort.

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including advanced Polyurethane (PU) and rubber midsoles designed to overcome the limitations of EVA.

We help you provide durable, breathable, and high-performance safety footwear tailored to your clients' specific industrial environments.

Contact us today to discuss your safety shoe requirements and request a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

People Also Ask

- Why is UHF Passive RFID Preferred Over Barcodes for Safety Boots in Farms? Boost Your Tracking Efficiency Today

- Why is an industrial-grade buffing machine essential for safety shoe sole-bonding? Achieve Superior Bonding Integrity

- Why is the assessment of comfort and fit in occupational protective footwear critical for preventing skin diseases?

- What factors should be considered when choosing safety shoes for a specific work environment? Match Hazards to Certified Protection

- What materials are used in non-steel safety toes? A Guide to Lighter, Safer Footwear

- How does S3 protection differ from S2? Matching Safety Footwear to Your Work Hazards

- What factors should be considered when choosing safety shoes? A Complete Guide to Workplace Foot Protection

- What are the dual benefits of high-performance safety shoes? Boost Protection and Comfort in Workplace Safety