Okay, so I've got this question about choosing safety shoes. My role here is to be the trusted technical advisor, the expert they can rely on. These are smart folks, they need a clear, unbiased guide.

The real question, though, isn't what factors matter, it's how to make the right choice without getting hurt or ripped off. They need a system, not just a shopping list.

I need to make sure I'm thinking critically, connecting ideas instead of just regurgitating info. I'll stay focused and use language everyone can understand. Short paragraphs, bolding key stuff, and some real-world examples should do the trick.

2. Analyzing the References:

I've got a bunch of references to work with. Some are better than others.

- Ref 1: Offers the basics: toes, uppers, etc. Good structure.

- Ref 2: Too generic. Won't use it.

- Ref 3: Bingo! This one's gold, with actionable advice on identifying hazards.

- Ref 4 & 5: Focus on comfort and performance, which is also important.

- Ref 6: Practical tips like getting fitted by an expert.

- Ref 7 & 8: I'll use the principles from these, but the focus is wrong for these users.

- Ref 9: The OSHA stuff is crucial for compliance.

3. Synthesizing and Structuring the Article:

I'll start with a direct answer: The primary factors are the hazards of your workplace, the required protection standards (like OSHA), and the need for proper fit and comfort for long-term wear.

Choosing safety shoes is all about hazard assessment. The right shoe neutralizes your risks while giving the necessary comfort and support.

I'll build it step-by-step:

-

H2: The Foundation: A Hazard-First Approach I'll start here.

- H3: Identify Your Specific Risks: Falling objects, electrical hazards, punctures, slips...

- H3: Decode the Protection Classifications: Explain the ratings based on Ref 9.

- H3: Verify Certification and Compliance: Check labels, use reputable suppliers.

-

H2: Deconstructing the Shoe: Key Components and Materials

- H3: The Safety Toe (Steel, Composite, Aluminum): The key here

- H3: The Outsole (Traction and Resistance): For traction.

- H3: The Midsole and Insole (Support and Protection): I'll mention puncture resistance and comfort.

- H3: The Upper Materials (Durability and Breathability): This is about long-lasting and breathable.

-

H2: Understanding the Trade-offs: Protection vs. Comfort

- H3: The Myth of Maximum Cushioning: I'll explain here. More is not always better.

- H3: The Weight of Protection: Heavier protection can be tiring.

- H3: Breathability vs. Water Resistance: I'll talk about this balancing act.

-

H2: Finalizing Your Choice: Fit and Function

- H3: Why Fit is Non-Negotiable: A bad fit is a hazard, Ref 5 is great.

- H3: Sizing for the Full Day: Feet swell during the day.

- H3: The Role of Insoles and Socks: Mention orthotics, thicker socks.

-

H2: Making the Right Choice for Your Environment

- I'll bullet-point some key takeaways.

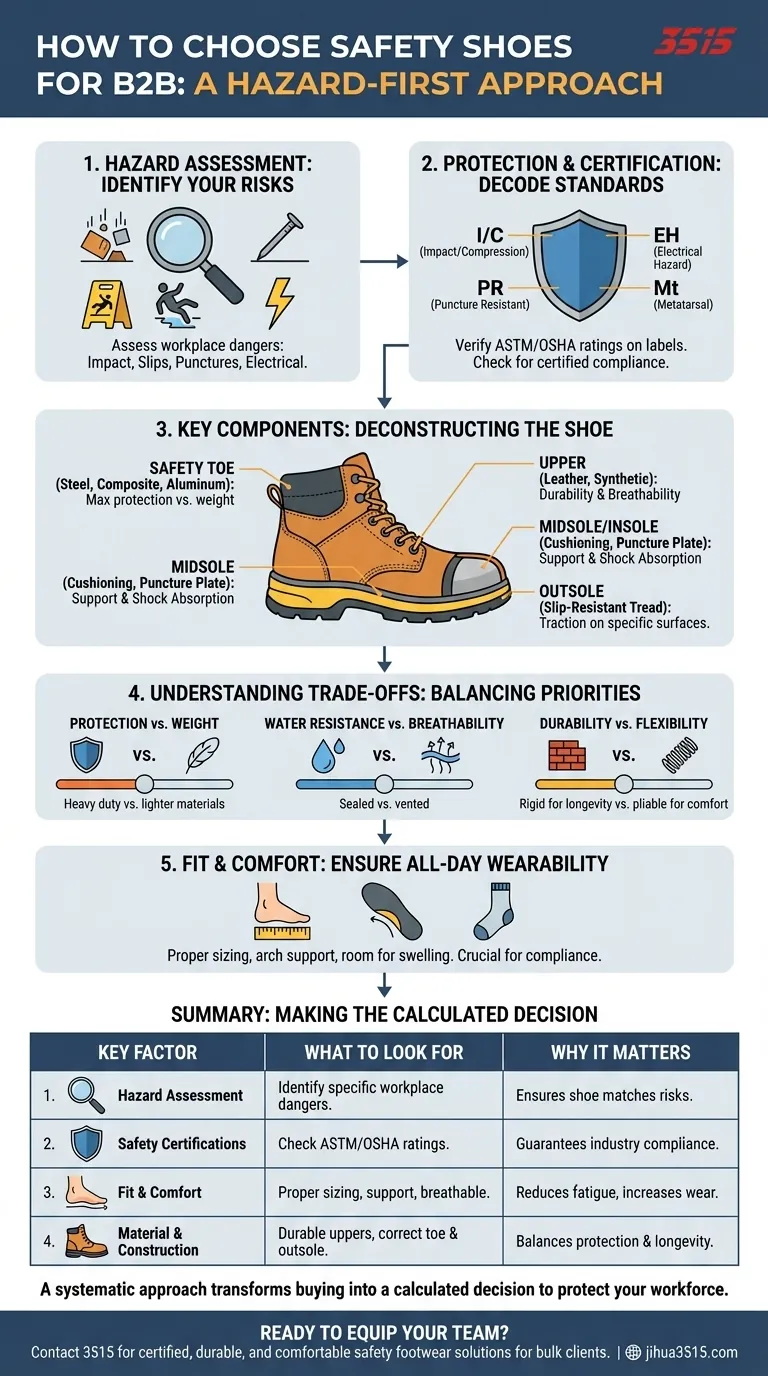

I'll end with something empowering: "A systematic approach transforms buying safety shoes from a guess into a calculated decision that protects your most valuable asset." To choose the right safety shoes, you must move beyond brand and style and focus on a three-part evaluation. The process involves first identifying the specific hazards of your work environment, then matching those risks to certified protection features, and finally ensuring a proper fit for all-day comfort and effectiveness.

The most common mistake is choosing safety shoes based on a single feature, like a steel toe, or general comfort. A truly effective choice is the result of a systematic hazard assessment, where the shoe is selected as a specific tool to neutralize the precise risks you face on the job.

The Foundation: A Hazard-First Approach

Before you even look at a shoe, you must analyze your environment. The shoe is a solution to a problem, and you must define the problem first.

Identify Your Specific Risks

The most critical step is a clear-eyed assessment of your daily tasks. Are you working around heavy machinery where objects could fall or roll onto your feet? Do you walk on surfaces slick with oil or water? Is there a risk of stepping on sharp objects like nails? Are you exposed to live electrical circuits?

Decode Protection Classifications

Safety shoes are not one-size-fits-all; they are highly specialized. Look for official classifications, such as those compliant with OSHA (Occupational Safety and Health Administration) standards. These labels certify protection against specific threats like impact (I), compression (C), metatarsal (Mt), puncture resistance (PR), or electrical hazards (EH).

Verify Certification

Authenticity is paramount. A shoe's protective claims must be backed by certification. You can verify this by checking the information on the shoe's label, purchasing from reputable suppliers, and asking for the manufacturer's technical data sheets if you have any doubts.

Deconstructing the Shoe: Key Components

Understanding the anatomy of a safety shoe allows you to evaluate how its construction aligns with your needs for protection, durability, and comfort.

The Safety Toe

This is the most well-known feature. Steel toes offer maximum protection but are heavier and conduct temperature. Composite toes (made of materials like carbon fiber, Kevlar, or plastic) are lighter, don't conduct electricity or temperature, but can be bulkier.

The Outsole

The outsole is your connection to the ground. Its primary job is slip resistance, with tread patterns and materials designed for specific surfaces like water, oil, or uneven terrain. It can also provide resistance to heat, chemicals, and abrasion.

The Midsole and Insole

The midsole provides cushioning and absorbs shock. For some jobs, a puncture-resistant plate is embedded in the midsole to protect against nails and other sharp objects. The insole provides arch support and cushioning, which is critical for comfort during long shifts.

The Upper Materials

The "upper" is the part of the shoe that covers the foot. Leather is a traditional choice known for durability and breathability. Synthetic materials can offer lighter weight and enhanced water resistance. The right choice depends on whether your priority is ruggedness, flexibility, or protection from moisture.

Understanding the Trade-offs

There is no perfect shoe; every design choice is a balance of competing priorities. Understanding these trade-offs is key to making an informed decision.

Protection vs. Weight

More protection often means more weight. A steel toe, metatarsal guard, and puncture-resistant plate create a highly protective but heavy shoe. This can lead to significant fatigue over a long day. Lighter composite materials are an alternative, but you must ensure they meet the required safety rating for your environment.

Water Resistance vs. Breathability

A fully waterproof boot is excellent for wet environments but will trap sweat, leading to discomfort and potential foot health issues. A more breathable shoe will be more comfortable in hot, dry conditions but offers little protection from the elements. Choose based on your most common working conditions.

Durability vs. Flexibility

Rigid, heavy-duty shoes are built for maximum durability in harsh environments but can feel stiff and require a break-in period. More flexible shoes are comfortable out of the box but may not stand up to the same level of abuse.

Making the Right Choice for Your Environment

Select your footwear by matching its specific, certified features to the hazards you have identified in your workplace.

- If your primary focus is protection from impact: Prioritize shoes with a certified safety toe (steel or composite) and consider a metatarsal guard if the risk involves the top of your foot.

- If your primary focus is preventing slips: Scrutinize the outsole's tread and material composition, ensuring it is rated for the specific surfaces you encounter, such as oily or wet floors.

- If your primary focus is all-day comfort: Look for lighter-weight composite toes and shoes with excellent arch support and cushioning, but never sacrifice the required safety certifications.

- If your primary focus is electrical safety: You must choose a shoe specifically rated for either Electrical Hazard (EH) to provide insulation or Static Dissipative (SD) to prevent static buildup.

A systematic approach transforms buying safety shoes from a guess into a calculated decision that protects your most valuable professional asset.

Summary Table:

| Key Factor | What to Look For | Why It Matters |

|---|---|---|

| Hazard Assessment | Identify risks like falling objects, slips, punctures, electrical hazards. | Ensures the shoe matches your specific workplace dangers. |

| Safety Certifications | Look for ASTM/OSHA ratings (e.g., I/C for impact/compression, EH for electrical hazard). | Guarantees the shoe meets industry standards for protection. |

| Fit & Comfort | Proper sizing, arch support, breathable materials, and room for movement. | Reduces fatigue and increases compliance for all-day wear. |

| Material & Construction | Durable uppers (leather/synthetics), slip-resistant outsoles, appropriate toe type (steel/composite). | Balances protection, durability, and comfort for long-term use. |

Ready to equip your team with the right safety footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities ensure you get durable, compliant, and comfortable footwear tailored to your specific workplace hazards.

Contact us today for a consultation and let us help you protect your workforce with reliable, high-performance safety shoes.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Sport Style Safety Boots for Bulk Orders

People Also Ask

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear