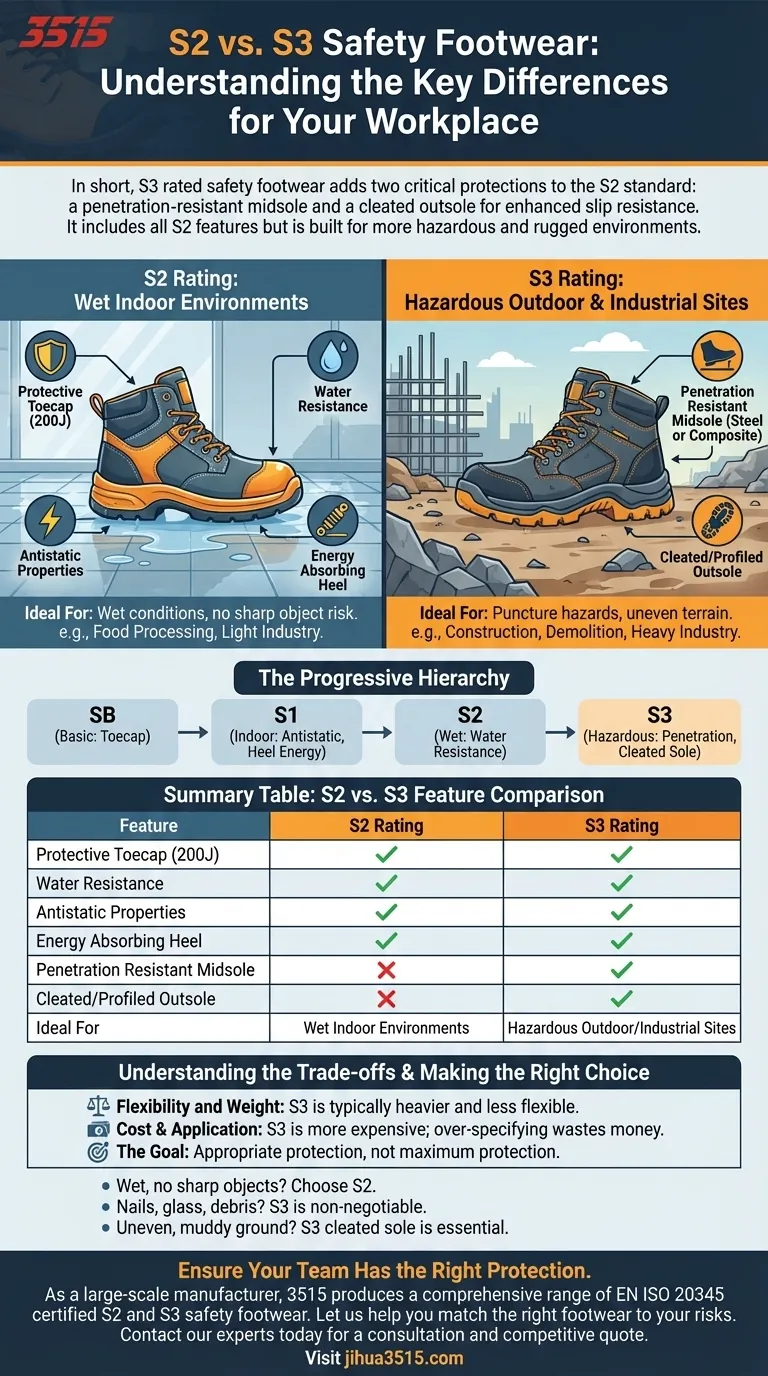

In short, S3 rated safety footwear adds two critical protections to the S2 standard: a penetration-resistant midsole and a cleated outsole for enhanced slip resistance. It includes all the features of an S2 boot, such as water resistance and a protective toecap, but is built for more hazardous and rugged environments.

The decision between S2 and S3 is not about which is "better," but about accurately matching the footwear's specific protections to the risks present in your work environment. S3 is designed for sites with puncture hazards and uneven terrain.

The Foundation: A Progressive Safety Standard

To understand the difference between S2 and S3, it's essential to see them as part of a progressive hierarchy. Each level builds upon the last, adding more specific protections.

SB: The Basic Requirement

All certified safety footwear starts at the SB (Safety Basic) level. This guarantees the most fundamental feature: a protective toecap resistant to a 200-joule impact.

S1: The Indoor Standard

The S1 rating adds features for drier, indoor environments. It includes everything in SB, plus a fully enclosed heel, antistatic properties, and energy absorption in the heel area.

S2: Adding Water Resistance

An S2 rating incorporates all S1 features but adds a critical element: water resistance and absorption. This makes it the standard for work in damp or wet conditions where there is no risk of sharp objects underfoot.

The Key Distinction: S3's Specialized Protections

The move from S2 to S3 introduces protections for physically demanding and hazardous job sites, specifically addressing threats from the ground up.

Penetration Resistance (P)

This is the most significant addition. S3 footwear includes a puncture-resistant midsole, typically made of steel or a composite material. This plate protects your foot from being pierced by sharp objects like nails, screws, or glass on the ground.

Profiled or Cleated Outsole

While S2 footwear has a standard slip-resistant sole, S3 specifies a profiled or cleated outsole. This means the sole has deeper lugs and a more aggressive tread pattern, providing superior grip and stability on loose, uneven, or soft surfaces like mud, gravel, and outdoor terrain.

Understanding the Trade-offs

Choosing a higher rating isn't always the best solution. It's vital to consider the practical implications of the additional features.

Flexibility and Weight

The penetration-resistant midsole, particularly if it's steel, can add weight and reduce the overall flexibility of the boot compared to an S2 equivalent. This can impact comfort over a long day if the protection isn't strictly necessary.

Cost and Application

S3 footwear is typically more expensive due to the extra materials and manufacturing involved. An S3 boot in a food processing plant (a wet environment with no puncture risk) would be over-specified, unnecessarily costing more and potentially being less comfortable than a more suitable S2 boot.

The Myth of "Over-Protection"

The goal is appropriate protection, not maximum protection. Wearing a heavy, rigid S3 boot in an environment that only requires S1P (S1 with puncture resistance) can lead to unnecessary fatigue without adding relevant safety benefits.

Making the Right Choice for Your Environment

Your risk assessment should be the deciding factor. Match the boot's rating directly to the hazards you face.

- If your primary focus is working in wet conditions with no risk of sharp objects on the floor: An S2 boot provides the necessary water resistance and safety features without the added weight and cost of S3.

- If your primary focus is working on construction sites, in demolition, or any environment with nails, glass, or sharp debris: The penetration-resistant midsole of an S3 boot is a non-negotiable safety requirement.

- If your primary focus is working outdoors on uneven, loose, or muddy ground: The superior grip from the cleated outsole of an S3 boot is essential for preventing slips and falls.

Choosing the right safety footwear is about matching the specific protections to the real-world hazards you face each day.

Summary Table:

| Feature | S2 Rating | S3 Rating |

|---|---|---|

| Protective Toecap (200J) | ✓ | ✓ |

| Water Resistance | ✓ | ✓ |

| Antistatic Properties | ✓ | ✓ |

| Energy Absorbing Heel | ✓ | ✓ |

| Penetration Resistant Midsole | ✗ | ✓ |

| Cleated/Profiled Outsole | ✗ | ✓ |

| Ideal For | Wet indoor environments (e.g., food processing) | Hazardous outdoor/industrial sites (e.g., construction, demolition) |

Ensure Your Team Has the Right Protection

Choosing the correct safety standard is critical for workplace safety and compliance. As a large-scale manufacturer, 3515 produces a comprehensive range of EN ISO 20345 certified S2 and S3 safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, ensuring you get durable, comfortable, and fully certified footwear tailored to your specific hazards.

Let us help you match the right footwear to your risks.

Contact our experts today for a consultation to discuss your requirements and receive a competitive quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

People Also Ask

- What materials are used for safety toes? Choose Steel, Composite, or Aluminum for Your Work Boots

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- Are employers required to provide steel-toe rubber boots at no cost to employees? Yes, under OSHA rules.

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What are the primary protective functions of composite-toe boots? A Guide to Modern Safety Footwear