Choosing the right safety shoe is not about finding a single "best" pair; it is about conducting a precise analysis of your work environment's unique hazards. The correct choice hinges on matching the specific certified protections of the footwear directly to the identified risks, such as impact from falling objects, electrical currents, or slippery surfaces.

The most critical error is selecting safety footwear based on a generic label. A truly effective safety program moves beyond this, requiring a formal hazard assessment of the specific work environment first, and only then selecting footwear certified to mitigate those exact risks.

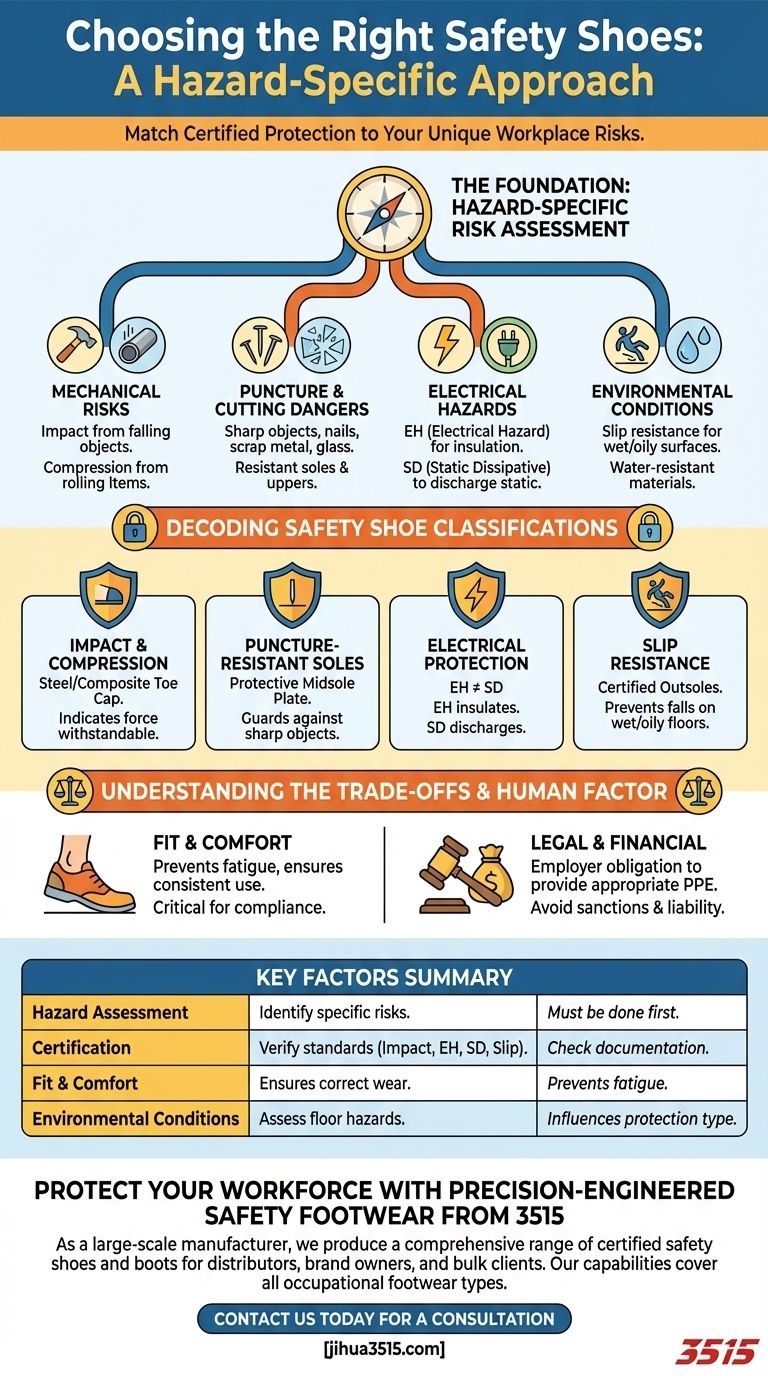

The Foundation: A Hazard-Specific Risk Assessment

Simply mandating "safety shoes" is insufficient and creates a false sense of security. A methodical assessment is the only way to ensure genuine protection and compliance.

Why a Generic Approach Fails

Every workplace has a unique risk profile. A shoe designed for a construction site may offer poor protection against the chemical or electrical hazards found in a laboratory or manufacturing plant.

According to the National Safety Council, tens of thousands of work-related foot injuries occur annually, many of which could be prevented by properly matched Personal Protective Equipment (PPE).

Identifying Mechanical Risks

The most common hazards are mechanical. Look for heavy objects, tools, or materials that could be dropped, causing an impact injury.

Also, consider items like pipes, wheels, or heavy carts that could roll over a foot, causing a compression injury.

Assessing Puncture and Cutting Dangers

Environments with nails, scrap metal, glass, or sharp tools require specific protection. The soles and uppers of the footwear must be resistant to puncture.

Evaluating Electrical Hazards

Working near live or even potentially live electrical circuits demands footwear with a certified Electrical Hazard (EH) rating.

Conversely, environments where the buildup of static electricity is a concern (e.g., electronics manufacturing) require Static Dissipative (SD) footwear to prevent damage to sensitive components.

Analyzing Environmental Conditions

The floor surface is a primary source of risk. Note the presence of water, oils, or other liquids that necessitate footwear with certified slip resistance.

Wet conditions also demand water-resistant or waterproof materials to ensure worker health and comfort.

Decoding Safety Shoe Classifications

Once you have identified the hazards, you must match them to the shoe's certified capabilities. This information is found on the shoe's label and in the manufacturer's technical data sheets.

The Importance of Certification

Always verify the authenticity of safety certifications. Source footwear from reputable suppliers who can provide technical documentation confirming the shoe meets specific national or international safety standards.

Core Protection: Impact and Compression

This is the most fundamental feature of a safety shoe, typically provided by a steel, alloy, or composite toe cap. The rating indicates the amount of force the toe can withstand.

Puncture-Resistant Soles

If you identified sharp objects as a risk, you must select a shoe with a protective plate in the midsole. This is a separate feature from the safety toe.

Choosing the Correct Electrical Protection

EH and SD ratings are not interchangeable. EH-rated shoes are designed to insulate the wearer from the ground, reducing the risk of electric shock. SD shoes are designed to safely discharge static electricity to the ground.

Understanding the Trade-offs

The safest shoe is useless if it isn't worn. Practical considerations are just as important as technical specifications.

The Human Factor: Fit and Comfort

A poorly fitting shoe can cause pain and fatigue, leading workers to improperly wear or avoid their PPE altogether.

The footwear must fit correctly, be appropriate for the duration of the shift, and allow for any necessary insoles.

Legal and Financial Implications

Employers are legally obligated to provide, maintain, and replace appropriate safety footwear in high-risk areas.

Failure to do so can result in significant sanctions from labor inspections and exposes the business to liability in the event of an injury.

Making the Right Choice for Your Environment

Your hazard assessment should directly guide your final selection. Prioritize the most significant risks for your specific operational context.

- If your primary focus is construction or heavy industry: Prioritize footwear with the highest available impact and compression ratings, along with puncture-resistant soles.

- If your primary focus is electrical work: Verify the shoe has the correct Electrical Hazard (EH) rating and is not confused with a Static Dissipative (SD) model.

- If your primary focus is a service or indoor manufacturing environment: Emphasize certified slip-resistant outsoles and consider comfort and weight for long shifts.

- If your primary focus is working around sharp objects: Ensure the footwear explicitly includes a certified puncture-resistant plate in the sole.

Ultimately, treating safety footwear as a critical, engineered control is the key to preventing injury and building a resilient safety culture.

Summary Table:

| Key Factor | Description | Key Consideration |

|---|---|---|

| Hazard Assessment | Identify specific risks in the work environment. | Must be done before selecting footwear. |

| Certification | Look for standards like impact, compression, EH, SD, or slip resistance. | Verify with manufacturer documentation. |

| Fit & Comfort | Ensures the shoe is worn correctly and consistently. | Prevents fatigue and improves compliance. |

| Environmental Conditions | Assess floors for liquids, sharp objects, or electrical hazards. | Directly influences the type of protection needed. |

Protect your workforce with precision-engineered safety footwear from 3515. As a large-scale manufacturer, we produce a comprehensive range of certified safety shoes and boots tailored for distributors, brand owners, and bulk clients. Whether your environment demands impact resistance, electrical hazard protection, or superior slip resistance, our production capabilities cover all types of occupational footwear. Contact us today for a consultation and let us help you build a safer workplace.

Visual Guide

Related Products

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Wholesale Leather Safety Boots with Customizable Protective Toe

People Also Ask

- Why is chemical-resistant and waterproof footwear essential for manual car wash operations? Ensure Worker Safety

- What boots do they wear on oil rigs? Essential Safety Footwear for Harsh Conditions

- When should safety shoes be worn? Protect Your Workforce from Common Hazards

- What additional protection levels were introduced beyond the standard S1-S3 ratings? S4 to S7 Explained

- What occupational hazards does industrial Safety Footwear address in high-risk environments? Essential Lab Safety Guide

- What is the primary role of material physics equipment in safety shoe outsoles? Balance Grip and Longevity

- Why are laced boots preferred over pull-on boots for firefighting? Superior Ankle Support for Maximum Safety

- Why are professional safety shoes essential for sanitation workers? Maximize Occupational Safety with Specialized Boots